10 repair kits and accessories, 900 series digital meters w / pulser, Electrical installation information – Fill-Rite 900D Series Digital Liquid Meter User Manual

Page 10

10

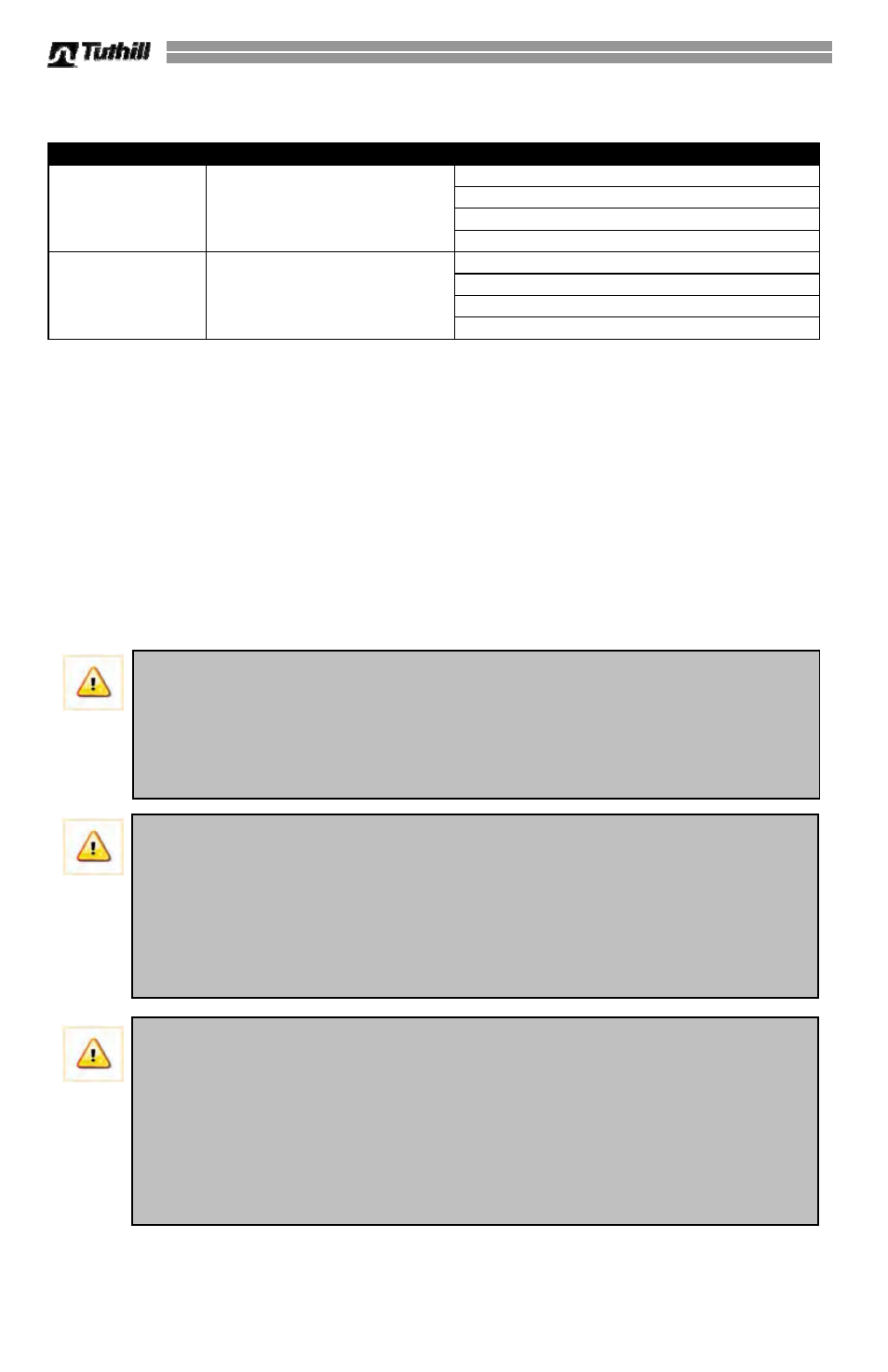

Repair Kits and Accessories

Kit #

Description

Contents

901DPMK300V

900 Series Meter (gallons)

with Inlet Flange for FR300

& FR700 Pumps

900 Series Meter (gallons)

Inlet Flange (4-hole)

Required O-rings

Required Fasteners

901DPLMK300V

900 Series Meter (liters)

with Inlet Flange for FR300

& FR700 Pumps

900 Series Meter (liters)

Inlet Flange (4-hole)

Required O-rings

Required Fasteners

900 Series Digital Meters w / Pulser

Certain 900 Series Digital Meters (model number suffix of DP) can be powered externally and

are equipped with an integral electronic pulser uni t for use with Fuel Management Systems.

The Fuel Management System must be configured for current sinking or contact closure types

of signals. The meter provides ten counts per unit of measure (in gallon, liter, and quart units of

measure only; pulser does not operate in ounce, pint, or user specific units of measure).

Electrical Installation Information

There are multiple electrical configurations for the 900D Series Digital Meter, featuring two

different power sources. It is critical that the meter be installed and wired correctly to ensure

correct, safe operation.

WARNING! Electrical wiring should be performed ONLY by a licensed electrician

in compliance with local, state, and national electrical codes (NEC/ANSI/NFPA 70,

NFPA30, and NFPA 30A in US installations for example), as appropriate to the

intended use of the meter.

The barrier must be properly connected to an earth

grounded. Improper installation of this meter and barrier can result in equipment

failure or damage, serious bodily injury, or death!

CAUTION! For meter installations using external power, the power should come

from a dedicated circuit. No other equipment should be powered by this circuit.

Wiring must be of sufficient size to carry the correct current for the meter. Voltage

drop will vary with distance to meter and size of wire; refer to the National

Electrical Code (NEC), or local codes, for Voltage Drop Compensation to be sure

you are using the correct size wire for your application. Wiring between the

barrier and meter

MUST NOT exceed 850’. Refer to “Typical Installation” wiring

information document DC000675-010 (included in the meter box) for details.

IMPORTANT! Explosion Proof versus Intrinsically Safe:

There is a distinct difference between a product that is “Explosion Proof” versus a

product that is “Intrinsically Safe”. Intrinsically Safe products are built so they do

not generate enough heat or energy to cause ignition or explosion. They are safe

to use in an explosive atmosphere (i.e.: around fuel tanks, etc. where explosive

vapors may be present). An Explosion Proof product is one that is designed to

contain an explosion internally if one should occur. Understanding the difference

between the two is critical when installing a new item to be certain the installation

is safe and to code.