M. compressed air requirements, Compressed air supply air pressure, Reversing timer spin/dwell adjustments – American Dryer Corp. AD-120ES User Manual

Page 38: Timing legend

34

American Dryer Corp.

113386 - 14

Compressed Air Supply

Air Pressure

Normal

80 psi

5.51 bar

551 kPa

Minimum Supply

70 psi

4.82 bar

482 kPa

Maximum Supply

90 psi

6.21 bar

621 kPa

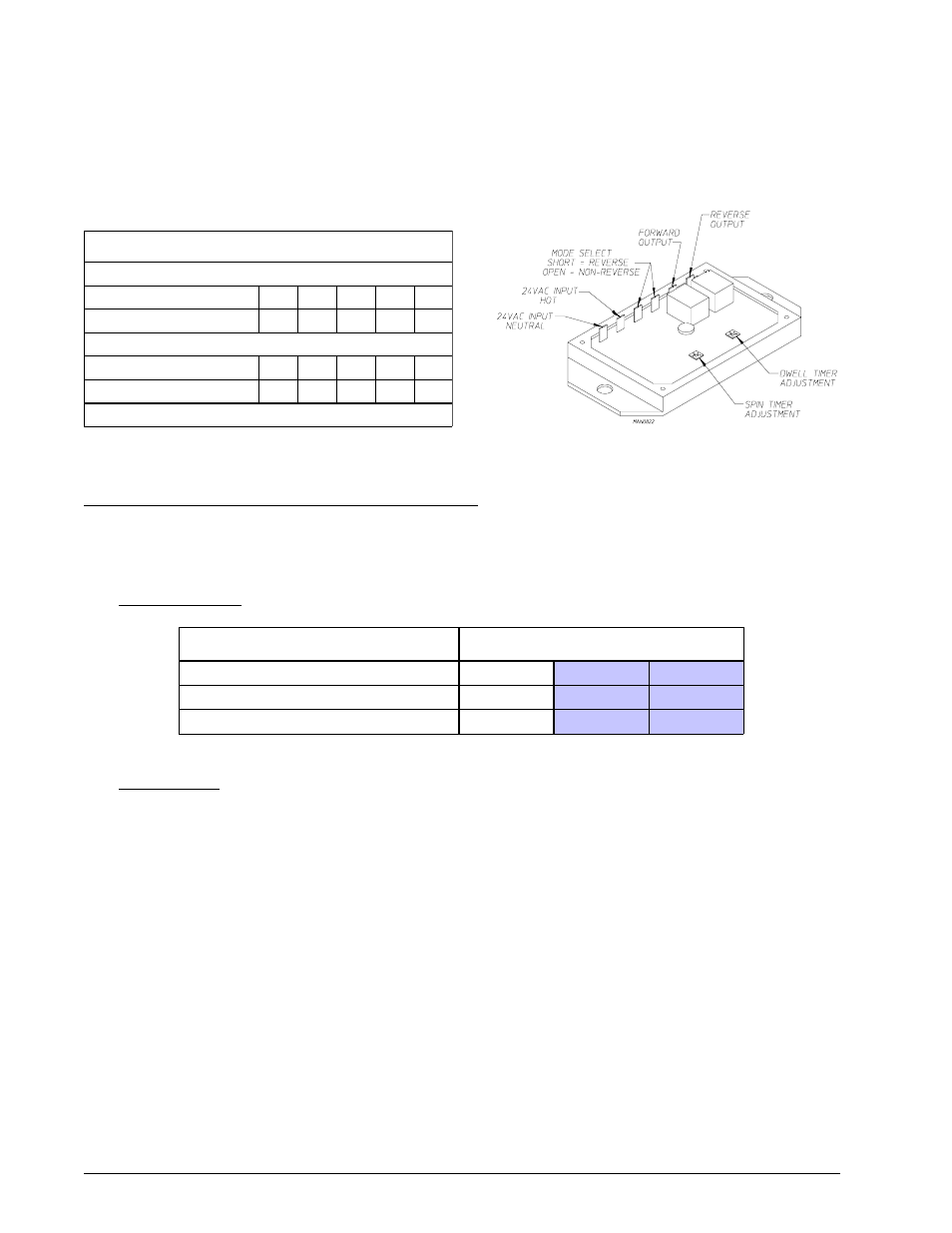

TIMING LEGEND

SPIN TIME

Adjustment Position Number

1

2

3

4

5

Time in Seconds*

30

60

90

120

150

DWELL (STOP) TIME

Adjustment Position Number

1

2

3

4

5

Time in Seconds*

5

6.3

7.6

8.9

10.2

* Values shown are +/- 1-second.

REVERSING TIMER SPIN/DWELL ADJUSTMENTS

Timer models have an electronic reversing timer in the electrical service box, which is located in the upper left

rear area of the dryer.

Both the Dwell (stop) Time and the basket (tumbler) Spin Time are adjustable by mode selection switches

located on the electronic timer (as noted in the illustration below).

M. COMPRESSED AIR REQUIREMENTS

Steam dryers require an external supply of compressed air, with a volume of 4.25 cfh @ 80 psi (0.12 cmh @ 5.51

bar, 551 kPa). Compressed air is necessary for the air operated steam damper.

1. Air Requirements

Shaded areas are stated in metric equivalents

2. Air Regulation

No air regulation or air filtration is provided with the dryer. External regulation/filtration of 80 psi (5.51 bar,

551 kPa) must be provided. It is suggested that a regulator/filter gauge arrangement be added to the

compressed air line just before the dryer connection. This is necessary to ensure that correct and clean air

pressure is achieved.