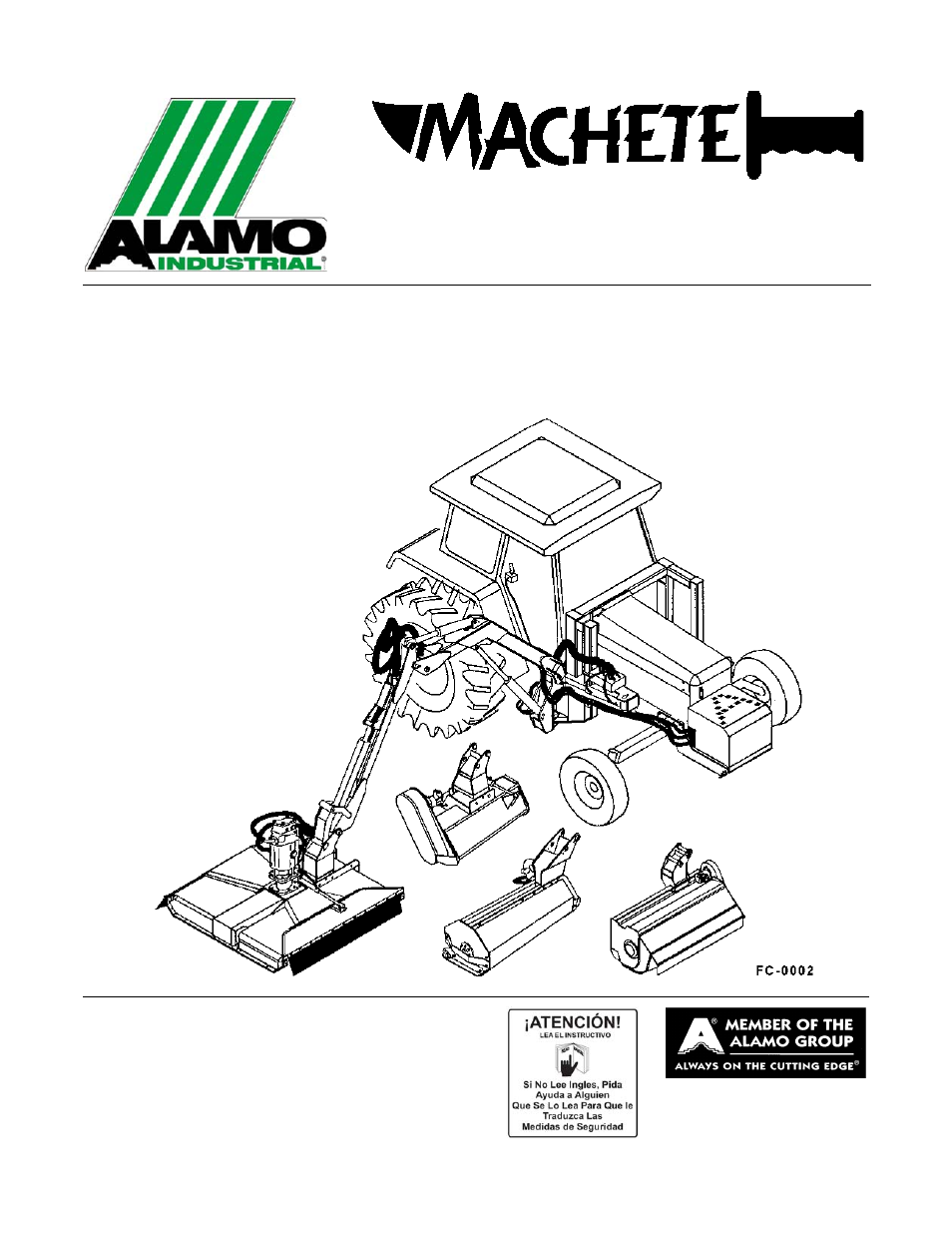

Alamo MACHETE FC-0002 User Manual

Operator’s manual, Alamo industrial

This manual is related to the following products:

Table of contents

Document Outline

- To the Owner/Operator/Dealer

- OPERATOR’S MANUAL

- MB BookTOC.pdf

- Safety Section.pdf

- General Safety Instructions and Practices

- Operator Safety Instructions and Practices

- Connecting & Disconnecting Implement Safety Instructions & Practices

- Equipment Operation Safety Instructions and Practices

- Decal Location

- DECALS ON TRACTOR/MOUNT KIT/ COUNTERWEIGHT

- 1. 02958241 1 DANGER Boom Mower Operators's Safety Decal (Front of Step Riser)

- 2. 02967827 {1} DANGER Multiple Hazard, Rotary (Rear of Top Step Riser)

- 3. 002369 {1} DANGER Multiple Hazard, Flail (Rear of Top Step Riser)

- 4. 03200285 1 CAUTION Watch Your Step (Level w/ Top Wgt Cover on Rear Frm Tube)

- 5. 02965093 1 INSTRUCT Do Not Over speed Engine (Cab Window or Fender)

- 6. 02960766 1 LOGO ALAMO (4 x 5) (Left Hood of Tractor)

- 7. 001650 1 LOGO ALAMO (7.26 x 7.5) (Front of Step Riser)

- 8. 02968953 1 NAME MACHETE (BLACK) (Left Hood of Tractor)

- 9. 00725746 1 PELIGRO Translate Safety Material (Left Frame)

- 10. 02962765 1 DANGER Pinch Point, Multiple (On Frame neat Swing Pin)

- 11. 02965262 1 DANGER Leak Detection, Hose Burst (On Frame Near Swing Pin)

- 12. nfs 1 SER PLT MACHETE Serial Plate (Boom Near Hitch Point)

- 13. 02971123 1 WARNING Pressurized Tank (Left of Tank)

- 14. 02979473 1 INSTRUCT Use ISO AW100 Hyd Oil (Left of Tank)

- 15. 02968953 1 NAME MACHETE (yellow) (Low Front Tank Cover)

- 16. 00776031 1 ------------ Canister, Operators Manual

- 17. 03200347 () REFLECT SMV Sign

- 18. 02962764 6 DANGER Pinch Point,(Folding, Scissor) (See Illustration)

- 19. 02968952 1 INSTRUCT Hose Connection Diagram(End of Dipper Boom)

- 20. 00757139 1 LOGO ALAMO by Terrain King (5 x 19) (Lift Boom)

- 21. 02968979 {2} Length 21 (for 21 foot boom)(Behind MACHETE on Boom)

- 22. 02968980 {2} Length 24 (for 24 foot boom)(Behind MACHETE on Boom)

- 23. 00769736 1 WARNING Use/Repair Shield & Guards (Left Front Deck)

- 24. 00769737 2 DANGER Blades/Thrown Objects (Rotary)(RT Frt LT Rr of Deck)

- 25. 02925100 1 IMPORTANT Genuine Parts, Rotary (Front Deck near Motor)

- 26. 02967867 1 DANGER Safety Gate Operation (Deck Behind Aux. Door)

- 27. 00757140 1 LOGO ALAMO (13 x 16) (Center Rear Deck in front of Ser Plt)

- 28. nfs 1 SER PLT Rotary Head Serial Plate (Deck Top Near Motor)

- 29. 02970889 1 SIZE 60" Rotary

- 30. 2738332 1 REFLECT Red Oblong Reflector

- 31. 2738333 1 REFLECT Yellow Oblong Reflector

- 1. 00769736 1 WARNING Use/Repair Shield & Guards

- 2. 00769737 2 DANGER Cutting Blades/Thrown Objects

- 3. 02725100 1 LOGO NAME BOOM AXE

- 4. 02925100 1 IMPORTANT Genuine Parts, Rotary

- 5. 02967827 1 DANGER Multiple Hazard, Rotary (*) (Mower

- 6. 02967867 1 DANGER Safety Gate Operation

- 7. 02970883 1 SIZE 50"

- 8. 00757139 2 LOGO ALAMO Industrial

- 9. 2738332 1 REFLECT Red Oblong Reflector

- 10. 2738333 1 REFLECT Yellow Oblong Reflector

- 11. 02979551 1 LOGO Alamo Ind. Sq. Green

- 1. 02979551 1 LOGO Alamo Industrial Square

- 1. 002369 1 DANGER Flail Multi Hazard

- 2. 02967668 1 DANGER Cutting Blades/Thrown Objects

- 3. 02967867 1 DANGER Operation of Safety Shield

- 4. 00725739 1 WARNING Use/Repair Shields & Guards

- 5. 00756059 1 WARNING Oil Leak Detection, Skin Penetration

- 6. 00758194 1 WARNING Pinch Point (V-Belt/Pulley)

- 7. 000108 1 INSTRUC Flail Operating Inst

- 8. 000678 2 INSTRUC Grease Fitting Inside

- 9. 00763977 1 INSTRUC Notice to Owner

- 10. 03200432 1 IMPORTANT Genuine Parts, Flail

- 11. 001650 1 LOGO ALAMO (7.26 x 7.5)

- 12. 00757139 1 LOGO ALAMO (4-1/2 x 16-1/2)

- 13. 02967592 3 NAME FML

- 14. 02967595 3 WIDTH 100H

- 15. NFS 1 SER PLT FML 100H Serial Plate

- 1. 002369 1 DANGER Multi-Hazard

- 2. 02967668 1 DANGER Cutting Blades/Thrown Objects

- 3. 02965141 1 DANGER Boom Flails

- 4. 00725739 1 WARNING Use/Repair Shields & Guards

- 5. 00758194 1 WARNING Pinch Points

- 6. 02925100 1 IMPORTANT Genuine Replacement Parts

- 7. 000108 1 INSTRUCT Flail Operate

- 8. 000678 1 INSTRUCT Grease Fitting

- 9. 00757139 1 LOGO Alamo

- 10. 02970885 1 WIDTH 60

- 11. 02970896 1 WIDTH 48

- 12. 02970886 1 NAME HDF Grass

- 13. nfs 1 S/N PLT Grass Serial Plate

- 1. 00757139 1 Decal - Alamo TK Logo

- 2. 02971931 1 Decal - Timber Cat

- 3. 00757140 1 Decal - Alamo Logo

- 4. 02973496 2 Keep Away - Amputation

- 5. 000678 1 Decal - Grease Fitting Inside

- 1. 02967827 1 Danger - Multi Hazard

- 2. 00756059 1 Warning - Oil Leak

- 3. 00769736 1 Warning - Use/Repair Guards

- 4. 02925100 1 Important - Replacement Parts

- 5. 00757139 1 Logo - Alamo TK Product

- 6. 02970888 1 Logo - Boom Ditcher

- 7. 999204 1 Logo - Ditcher

- 8. nfs 1 S/N Plate

- 9. 3710151 4 Metal Tacks

- 1. 00758194 1 WARNING V-Belt Pinch

- 2. 00769736 1 WARNING Use/Repair Shields

- 3. 00769737 1 DANGER Cutting Blades

- 4. 02925100 1 CAUTION Genuine Parts

- 5. 02958241 1 DANGER Operator Safety

- 6. 02962764 1 DANGER Pinch Point

- 7. 00756004 1 DANGER Guard Missing

- 8. 02965262 1 DANGER Leak/Hose Burst

- 9. 02967827 1 DANGER Multi hazard Rotary

- 10. 00757139 1 LOGO Alamo By Terrain King

- 11. 02974998 1 LOGO Buzzbar

- 12. D138 1 DECAL Blade Rotation

- 13. 02975158 1 WARNING Hearing Protection

- 14. 02975170 1 DANGER Foot/Leg Contact

- 15. 02975515 1 WARNING Disconnect Solenoid

- 16. 02975516 1 CAUTION No Hitch Post Here

- 17. 02975514 1 ------------ Pitch Adjust

- 18. nfs 1 ------------ Serial Plate

- 19. 1458392 1 REFLECT Red Reflector

- 20. 1458393 1 REFLECT Yellow Reflector

- 21. 02961134 1 ------------ Patent Pending

- 1. 02962764 6 Pinch Points

- 2. 02968952 1 Hose Connection Diagram

- 3. 02968953 2 Machete

- 4. 02980001 2 Boom Length 17’

- 5. 00757139 2 Logo (Alamo By Terrain King)

- 1. 02979551 1 LOGO Alamo Industrial Square

- SAFETY SECTION

- Decal Description

- Federal Laws and Regulations

- DECALS ON TRACTOR/MOUNT KIT/ COUNTERWEIGHT

- Introduction.pdf

- Operation Section.pdf

- ALAMO INDUSTRIAL MACHETE BOOM MOWER

- OPERATING INSTRUCTIONS

- 1. OPERATOR REQUIREMENTS

- 2. TRACTOR REQUIREMENTS

- 3. GETTING ON AND OFF THE TRACTOR

- 4. STARTING THE TRACTOR

- 5. CONNECTING ATTACHING HEADS TO THE BOOM

- 6. PRE-OPERATION INSPECTION AND SERVICE

- 7. OPERATING THE BOOM JOYSTICK CONTROL

- 8. DRIVING THE TRACTOR AND IMPLEMENT

- 9. OPERATING THE BOOM UNIT AND ATTACHED HEAD

- 10. TRACTOR, BOOM, AND ATTACHED HEAD STORAGE

- 11. TRANSPORTING THE TRACTOR AND IMPLEMENT

- Maintenance Section.pdf

- MAINTENANCE SECTION

- SERVICE OF SPINDLE HOUSING (FIGURE Mnt-0006)

- START UP PROCEDURE

- 1. Read all safety instructions. Decals on the Machete Boom warn you of particular and multiple hazards. Many decals are attached close to part of the Machete Boom where there is a possible hazard. Read and make sure you understand the safety message...

- 2. Before operating, read all the safety and operating instructions in the Operators Manual for both the tractor and mower.

- 3. When the hydraulic tank has been filled and the mower unit properly assembled, the unit should be started up. NOTE: Make sure that no materials, tools, or jacks, have been left under the mower head. Make sure the front and rear of the mower are pr...

- 4. Start the tractor and idle at a slow engine speed until oil is being pumped.

- 5. Engage the Cutter Control Valve at low engine rpm and run the mower slowly for a short period until all air is removed from the hoses. Keep all persons WELL CLEAR of mower since Blades can THROW OBJECTS with great velocity for a considerable dista...

- 6. With the area clear of any ground and overhead obstructions, work each cylinder on the boom one at a time, several times, to expel any air in the Hoses and Cylinders.

- 7. Run the Mower Head for 5 minutes. While the tractor is idling, blocked, wearing protective clothing and eye protection, CAREFULLY check for leaking hydraulic fittings, hoses and ports at this point with a piece of cardboard, DO NOT USE YOUR HAND! ...

- 8. Check the fluid level in the Hydraulic Tank on the Tractor, and add oil if required. As the air has been forced out of the Cylinders and Hoses, it goes into the Hydraulic Tank and reduces the oil level. Check your Tractors Operators Manual for the...

- TIMBER CAT HEAD

- BUZZBAR HEAD

- FLAIL AXE HEAD

- Grass Flail Head

- General Information on Flail Mower Vibration

- FLAIL MOWERS

- INFORMATION BULLETIN NO. 5

- The cutter shaft will run out of balance if:

- 1. Wire, rope, string, rags, etc., around the cutter shaft, are holding the knives in a folded back position. Remove such foreign objects and be sure all knives are free to swing to the extended position.

- 2. Knives are missing or broken. Replace missing or broken knives.

- 3. Knife hanger lugs are broken off shaft. This condition usually results from continued operation in contact with large hard objects where the knife hanger lugs themselves are hitting the hard objects. Lugs should be replaced using arc welding equip...

- 4. Cutter shaft ball bearings are worn enough to have radial "play" in them. Replace ball bearing and other worn parts to eliminate "play".

- 5. Shaft is bent. The shafts are straight within a couple of thousandths of an inch when they are made. It is possible that they will become bent in use, such as if the shaft is hooked on a stump while the tractor is moving forward at a good speed.

- 6. Shafts are operated at improper speed. Rotating shafts have what is known as a natural period of vibration. The same is true of the cutter shafts on the Flail Mowers.

- The cutter shaft will run out of balance if:

- SPINDLE SERVICE PROCEDURE 02960553B and 02960553C

- 1. Remove blade bar or pan.

- 2. Remove hydraulic motor.

- 3. Remove spindle assembly from mower deck.

- 4. Drain remaining lubricant from housing.

- 5. Using a 3/16" cape chisel, bend out the staking indentations on each side of the bearing adjusting nut. To do this, place the chisel in the groove and parallel to the shaft. Drive the chisel downward until the indentation is free of the shaft and ...

- 6. Using the same chisel, straighten the tang on the lockwasher (if equipped with a lockwasher).

- 7. Remove bearing adjusting nut and lockwasher (if equipped). Discard these parts. They are not re- usable. Install a new adjusting nut when assembling.

- 8. Screw the original blade bar bolts into the flange of the spindle shaft until they contact the bearing ring (see Figure 2).

- 9. In a clockwise pattern, rotate each bolt 1/4 turn (see Figure 3). Continue turning the bolts 1/4 turn at a time (maximum of 3 turns), until the special shanked bolts (P/N 02964353) will thread into the spindle.

- 10. Remove the original bolts and replace them with the shanked bolts. Screw the shanked bolts in until they contact the bearing ring.

- 11. In a clockwise pattern, rotate the bolts 1/4 turn at a time until the spindle is free from the housing.

- 12. Remove the seal retaining ring from the housing using a flat screwdriver or similar tool.

- 13. Remove the seal and bearing.

- 14. A punch or similar tool can be used to remove the bearing cups from the housing if the cups are not to be re-used.

- CLEANING

- INSPECTION

- ASSEMBLY

- 1. Place upper bearing cones in bearing oven.

- 2. Seat bearing cups (outer races) in housing using a press and proper installation tools in good condition. CUPS MUST BE FULLY SEATED. If bearing cup cocks in bore and seizes, do not continue to assemble spindle.

- 3. Lubricate lower bearing cone with LPS.

- 4. Coat the outside of the seal with silicone and install the lower bearing, seal, and retaining ring into the housing, using the correct seal installer.

- 5. Place a light film of silicon or permatex on the inside diameter of the bearing ring and seat the ring on the spindle shaft, using the proper tool and press.

- 6. Lightly lubricate the lip of the seal.

- 7. Using the 2-3/4" tubing to prevent the cup and cone from contacting each other, press the spindle shaft through the lower bearing and seal. Make sure the bearing is seated against the bearing ring.

- 8. Place Locktite on threads of the bearing adjusting nut (flange nut).

- 9. Using gloves, install the heated upper bearing cone on the shaft immediately and push it all the way against the cup. Lubricate the bearing with LPS.

- 10. Install the bearing adjusting nut. Tighten the nut until the spindle shaft can not be turned. Loosen the nut 1/4 turn. Place a soft, clean cloth over the top of the spindle assembly. Place an aluminum block over the end of the spindle shaft and s...

- 11. Remove the cloth, being careful not to allow any contamination into the spindle. Tighten the nut until a rolling torque of 16-21 inch-pounds is reached. (If the seal was not lubricated, add 10 inch-pounds).

- 12. Stake the nut with a blunt, round nosed punch. Do not tear the nut.

- 13. Install the grease fitting into the hole in the center of the housing (between the bearings) and fill the housing with EP#2 grease, stopping when the lubricant covers the upper bearing (approximately 11 oz.).

- 14. Install the breather plug in the top hole.

- 15. Install spindle in mower deck and assemble in reverse order. Torque the blade bar or pan bolts to 400 ft-lbs. Torque motor to spindle bolts to 85 ft-lbs. Torque spindle to deck bolts at 175 ft-lbs.

- LUBRICATION INFORMATION

- HYDRAULIC OIL, FILTERS, AND COMPONENTS

- TANK FILL

- HARDWARE

- PROPER TORQUE FOR FASTENERS

- Back Cover.pdf

- Keep children away from danger all day, every day...

- Equip tractors with rollover protection (ROPS) and keep all machinery guards in place...

- Please work, drive, play and live each day with care and concern for your safety and that of your family and fellow citizens.

- TO THE OWNER/OPERATOR/DEALER

- ALAMO-INDUSTRIAL

- LIMITED WARRANTY

- 1. LIMITED WARRANTIES

- 1.01. Alamo Industrial warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser

- 1.02. Manufacturer will replace for the Purchaser any part or parts found, upon examination at one of its factories, to be defective under normal use and service due to defects in material or workmanship.

- 1.03. This limited warranty does not apply to any part of the goods which has been subjected to improper or abnormal use, negligence, alteration, modification, or accident, damaged due to lack of maintenance or use of wrong fuel, oil, or lubricants, ...

- 1.04. Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any nature on behalf of Manufacturer.

- 2. REMEDIES AND PROCEDURES.

- 2.01. This limited warranty is not effective unless the Purchaser returns the Registration and Warranty Form to Manufacturer within 30 days of purchase.

- 2.02. Purchaser claims must be made in writing to the Authorized Dealer (“Dealer”) from whom Purchaser purchased the goods or an approved Authorized Dealer (“Dealer”) within 30 days after Purchaser learns of the facts on which the claim is based

- 2.03. Purchaser is responsible for returning the goods in question to the Dealer.

- 2.04. If after examining the goods and/or parts in question, Manufacturer finds them to be defective under normal use and service due to defects in material or workmanship, Manufacturer will:

- (a) Repair or replace the defective goods or part(s) or

- (b) Reimburse Purchaser for the cost of the part(s) and reasonable labor charges (as determined by Manufacturer) if Purchaser paid for the repair and/or replacement prior to the final determination of applicability of the warranty by Manufacturer.

- 2.05. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Manufacturer and for returning the goods to the Dealer, whether or not the claim is approved. Purchaser is responsible for the transportation cost for...

- 3. LIMITATION OF LIABILITY.

- 3.01. MANUFACTURER DISCLAIMS ANY EXPRESS (EXCEPT AS SET FORTH HEREIN) AND IMPLIED WARRANTIES WITH RESPECT TO THE GOODS INCLUDING, BUT NOT LIMITED TO, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

- 3.02. MANUFACTURER MAKES NO WARRANTY AS TO THE DESIGN, CAPABILITY, CAPACITY, OR SUITABILITY FOR USE OF THE GOODS.

- 3.03. EXCEPT AS PROVIDED HEREIN, MANUFACTURER SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO PURCHASER OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS, OR DAMAGE CAUSED OR ALLEGED TO BE CAUSED DIRECTLY OR INDIRECTLY BY THE GOODS INCLU...

- 3.04. NO ACTION ARISING OUT OF ANY CLAIMED BREACH OF THIS WARRANTY OR TRANSACTIONS UNDER THIS WARRANTY MAY BE BROUGHT MORE THAN TWO (2) YEARS AFTER THE CAUSE OF ACTION HAS OCCURRED.

- 4. MISCELLANEOUS.

- 4.01. Proper Venue for any lawsuits arising from or related to this limited warranty shall be only in Guadalupe County, Texas.

- 4.02. Manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall be deemed to be a waiver of any other term.

- 4.03. If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

- 4.04. Applicable law may provide rights and benefits to purchaser in addition to those provided herein.

- ALAMO INDUSTRIAL

- LIMITED WARRANTY

- Safety Video.pdf