Timber cat head, Maintenance – Alamo MACHETE FC-0002 User Manual

Page 159

MAINTENANCE

MACHETE BOOM 3/09

Maintenance Section 4-13

©2009 Alamo Group Inc.

MAINTENANCE

TIMBER CAT HEAD

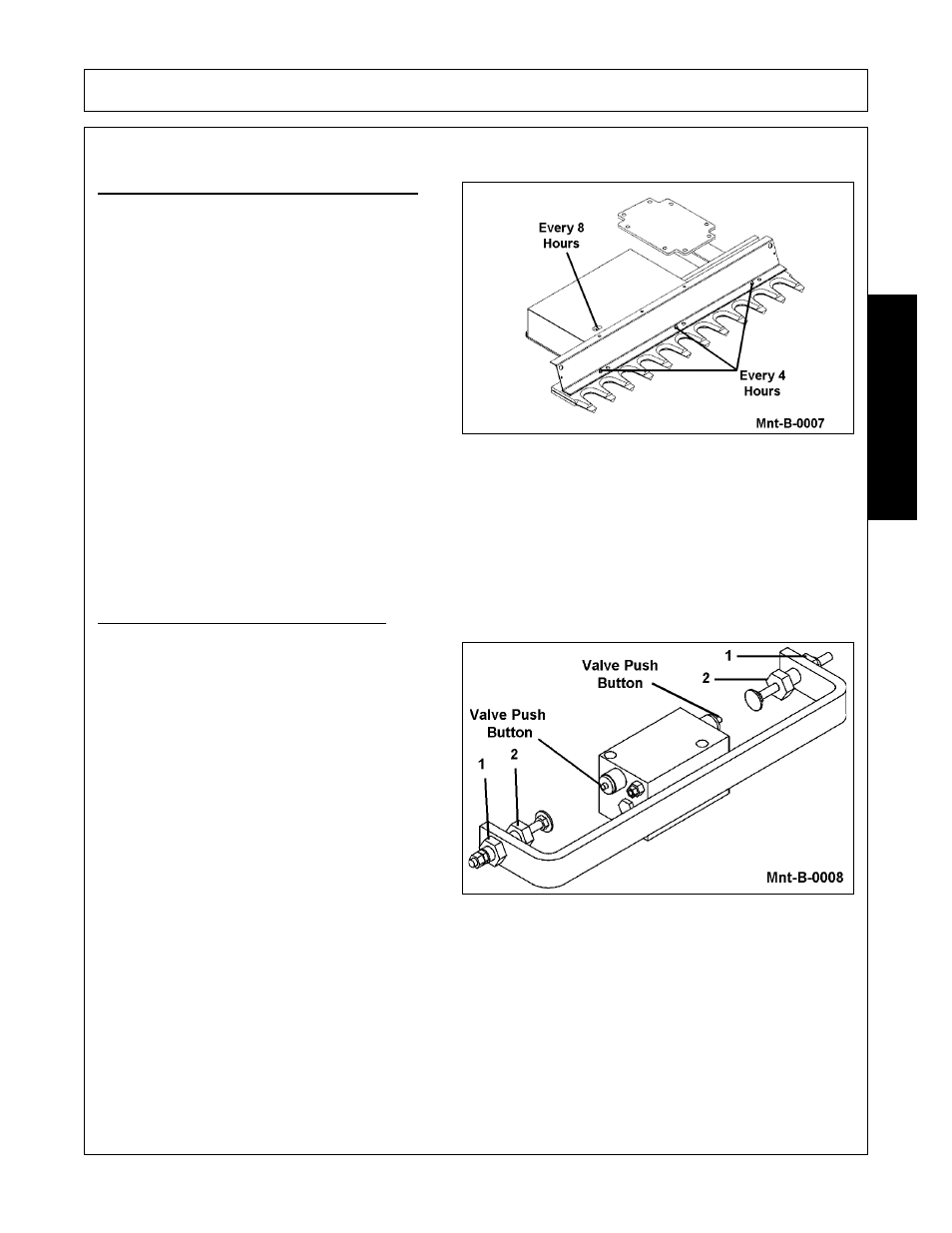

Lubrication/Daily Checks (Figure Mnt-0007)

Lubricate the grease fittings on top of the blade bar

every 4 hours. See Figure Mnt-0007.

Every 8 hours, lubricate the cylinder grease fitting

through the top slot in the cover. See Figure Mnt-

B-0007. Every 8 hours, check all bolts and nuts for

proper tightness. Tighten any bolt or nut found to

be loose. Periodically check the hydraulic

connections for oil leaks. Visually inspect the hoses

for damage and replace as necessary. Periodically

inspect blade stroke adjustment by running the

head at normal operating speed (540 PTO RPM)

and checking that the upper and lower blades line-up perfectly the instant of reversal (when they change

direction).

Improper adjustment is also indicated by an abnormally high shock load on the hydraulic system during blade

reversal. This is due to the hydraulic cylinder reaching its stroke limit, causing the pressure relief reversing

components to engage. Continuous operation in this mode will result in oil overheating and premature failure

of components. If the unit is improperly adjusted, follow the stroke adjustment procedures below.

Stroke Adjustment (Figure Mnt-B-0008)

Position the head in a safe area for operation. If

necessary, barricade the head to prevent contact

while it is being operated.

Remove the cover and loosen the two jam nuts

(Item 1). See Figure Mnt-B-0008. Screw the two

spring bolt assemblies (Item 2) in toward the valve

push buttons. Start the unit and bring the speed up

to normal operating speed (540 PTO RPM). Check

the blade overlap. Adjust the spring bolt assemblies

(Item 2), one by one until the upper and lower

blades perfectly align in the instant of reversal.

Never adjust the bolt assemblies to a point where

the hydraulic cylinder reaches it's stroke limit! This is indicated by an abnormally high shock load on the

hydraulic system due to the pressure relief reversing components being engaged. Continuous operation in this

mode will cause premature component failure and hydraulic oil overheat. Once proper adjustment has been

achieved, tighten the jam nuts (Item 1) and replace cover.