AAON V3-E User Manual

Page 19

19

Belts

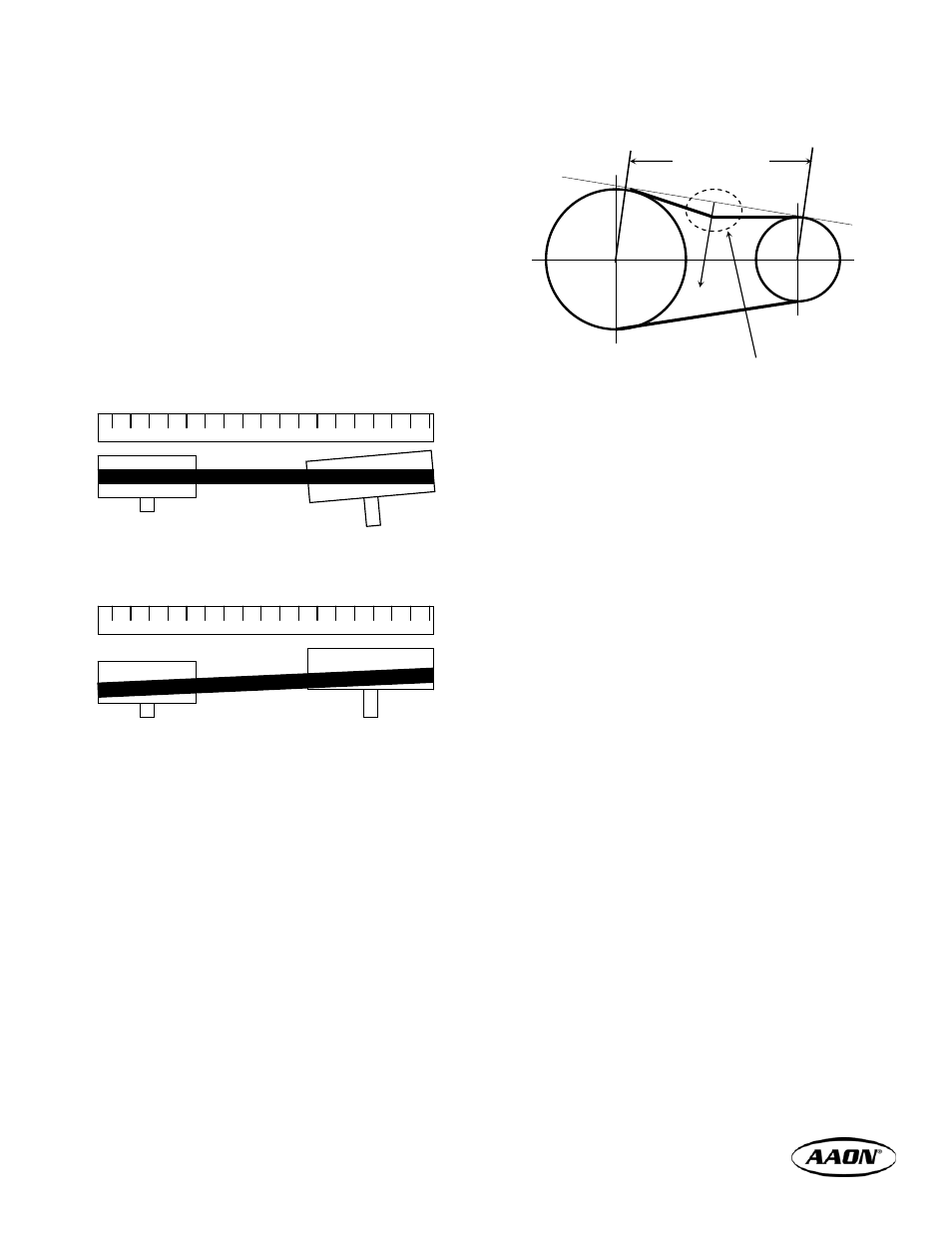

Belt drive misalignment is one of the most common

causes of premature belt failure. A belt can be

destroyed in a matter of days if the drives have been

aligned incorrectly.

The most common tool for measuring misalignment is

a straightedge. Hold the straightedge flush across one

pulley to gauge the degree of misalignment of the two

sheaves. The maximum allowed misalignment is one

half degree of angular misalignment, and 1/10

th

of an

inch per foot between sheave centers for parallel

misalignment.

Figure 19a, Angular Misalignment

Corrected by moving the position of the motor.

Figure 19b, Parallel Misalignment

Corrected by adjusting sheaves on one, or both shafts.

Frequent belt tensioning is highly recommended. Most

belt manufacturers would suggest a retensioning after

as little as 8 hours of operation. A simplified method of

adjusting tension is to gauge the amount of force

required to deflect the belt by 1/64

th

of an inch per inch

of distance between sheave centers. For example, if

the sheaves are 20 inches apart, then the amount of

deflection with the forces listed below is 20/64

th

(5/16

th

)

of an inch.

Figure 19c, Belt Deflection

Indoor Coils

Coils should be inspected and cleaned annually to

ensure there is no obstruction to airflow. Dirty

evaporator coils will eventually freeze up, and often

result in a time consuming, and expensive service call.

Clean filters will help to prevent dirt from accumulating

on the evaporator, however the evaporator should be

cleaned annually with a soft bristled brush, and/or a

non-corrosive coil cleaning solution.

Heating

Electric

Set thermostat in the heat mode; call for heat to

engage all electric heat strips. Check blower for

proper rotation and voltage. Measure the amperage

and voltage. Compare them to the nameplate data.

If applicable, check remote heat pump condensing unit

as per the manufacturer’s recommendations.

Steam or Hot Water

Set thermostat in the heat mode. Observe supply

blower for proper rotation and voltage. Check boiler or

hot water operation according to the manufacturer’s

instructions. Check control flow valves for correct

operation and settings per the manufacturer’s

instructions.

Straightedge

Pulley

Pulley

Belt

Straightedge

Pulley Pulley

Belt

Sheave Centers

Force

Deflection = 1/64

th

in.

per inch of length

Deflections required for:

“A” belts: 4 to 6 lbs.

“B” belts: 6 to 10 lbs.

“C” belts: 10 to 18 lbs.