AAON V3-E User Manual

Page 13

13

Mounting & Suspension

Floor Mounted

Make sure the unit is level, and mounted on a field-

supplied platform with a minimum height of 6” to allow

for proper fall on the condensate line. Other installation

provisions may be necessary according to job

specifications. V2 air handlers are designed for upflow

applications only.

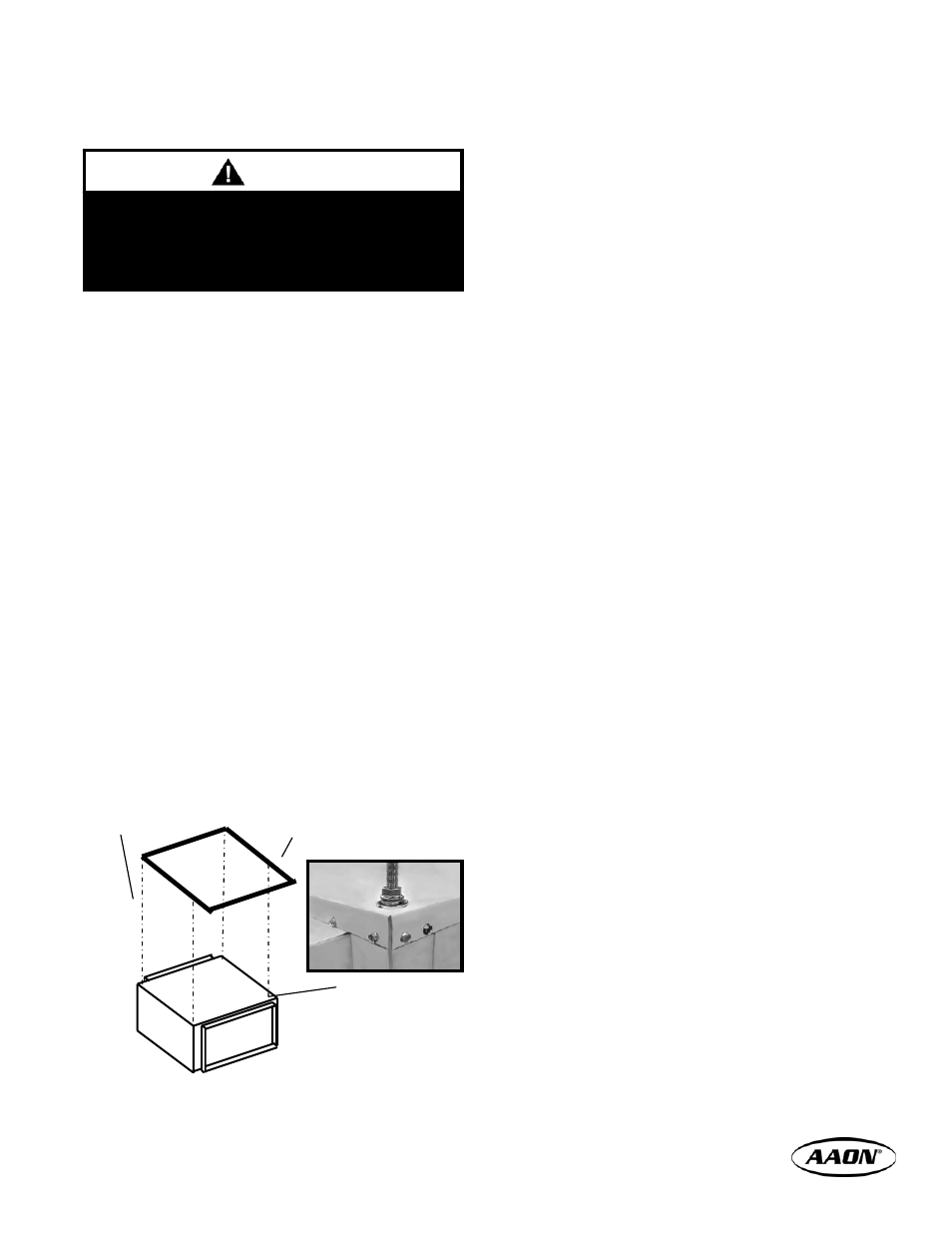

Suspended

The H2 horizontal air handler is equipped for

suspended installations. The air handler should be

lifted into position by supporting the unit with the skid

used for shipping. Suspend the air handler from its

four corners with field supplied 3/8”-16 NC “all-thread”

rods. Screw the rods into the threaded steel retainer

wells built into the air handler top and secure with nuts.

The air handler must be installed level and care should

be taken to prevent damage to the cabinet. Other

installation provisions may be necessary according to

job specifications.

Figure 13a, Suspended Horizontal Air Handler

Sealing

It is very important to keep outside air from infiltrating

the unit cabinet. Seal all piping penetrations with

Armaflex, Permagum, or other suitable sealant. Also

seal around drain connections, electrical connections,

and all other inlets where air may enter the cabinet.

This is especially important when the unit is installed in

an unconditioned area.

Cooling Equipment

Air Handler Equipped with Refrigerant Coil (DX)

This section is not intended to provide all the

information required by the designer or installer of the

refrigerant piping between the condensing units and

the air handler. The appropriate sections of the

ASHRAE Guide and the ASME standards should be

used for final information. Acceptable system design

and installation will include consideration as follows:

− Piping from the condensing unit to the indoor air

handler is the responsibility of the installing

contractor.

− Only clean “ACR” tubing should be used.

− Piping should conform to generally accepted

practices and codes.

− Care must be taken not to cross the circuits on

multiple circuit systems.

− Once piped, the interconnecting piping and air

handler MUST BE evacuated to 50 microns or

less; leak checked and charged with refrigerant as

indicated on the unit name plate.

− Make sure air handler thermal expansion valve

bulb is mounted with good thermal contact on the

correct suction line on a horizontal section, close

to the evaporator in the 4 or 8 o’clock position and

well insulated. Care must be taken to ensure the

bulb is mounted on the correct suction line on

multiple circuit systems.

− The suction line (and hot gas bypass line if

present) should be insulated for its entire length

Lines should be fastened and supported according to

local codes.

Air Handler Equipped with Chilled Water Coil

Water supply lines must be insulated with closed cell

type pipe insulation or insulation that includes a vapor

barrier. Lines should be properly fastened, drained

and supported according to local code requirements.

Field Supplied

All-thread Rod

Ceiling

Support

Structure

Wells for

Threaded Rod –

All Corners

An auxiliary (emergency) drain pan is

recommended for all applications where there is a

risk of water damage to surrounding structure or

furnishings. Refer to local codes.

NOTE