Warning, Installation – AAON V3-E User Manual

Page 12

www.aaon.com

12

3. Installation

General

H2/V2 air handling units are designed as a self-

contained heating, cooling, or combination unit for

indoor installation only. The use of refrigerant, chilled

water, electric resistance, steam, or hot water as

operating mediums will be dictated by design of the

heating and cooling coils installed in the unit. Flexible

connectors are required on all duct connections and

installed to minimize air leaks.

Certification

Cooling Models

a) Certified for use with a commercial

condensing or chilled water remote unit (with

or without compressor(s))

b) Certified for indoor installation only.

Steam or Hot Water Heat Models

a) Certified for indoor installation only.

Electric Heat Models

a) Certified as an electric warm air furnace with

or without cooling coil.

b) Certified for indoor installation only.

Codes & Ordinances

System should be sized in accordance with National

Warm Air Heating and Air Conditioning Association

Literature, or the Guide of American Society of

Heating, Refrigeration and Air Conditioning Engineers.

The installation must conform with local building

codes, or in the absence of local codes, with (United

States) “ANSI / UL 1995”, (Canada) current, C.S.A.

Standard C22.2, No. 236, Canadian Electrical Code

Part 1, and C.S.A. Standard B52 Mechanical

Refrigeration Code, and Local Plumbing or Waste

Water Codes.

Handling

Be aware of what is contained in the equipment!

Dependent upon the optional accessories that were

ordered, this equipment may contain fragile

components and delicate electronics. Although the

unit is constructed of sturdy materials, avoid impacts

and handling methods that may damage internal

apparatus and structure, or the exterior painted

surfaces of the unit. Take care not to apply destructive

force to coils, coil and drain stub-outs, or other parts

protruding beyond the extents of the unit casing.

Always handle the unit by its exterior casing, and

never by any of the protruding parts.

Keep equipment free from debris, and construction

waste during installation. Foreign materials may

adversely affect unit operation resulting in premature

failures that will not be covered by the manufacturer’s

warranty. Attach all service panels, and cover all

exposed equipment when work is not being performed.

Leave unit protected from other construction until start-

up is to occur.

Service & Installation Clearance

Before setting the air handler into place, caution must

be taken to provide clearance for unit panels/doors

that must be accessible for periodic service. These

areas contain the controls, safety devices, refrigerant

or water piping, shut-off valves and filter access.

H2/V2 air handlers require a minimum of 36 inches of

service clearance on the access panel side of the

unit in order to ensure room for removal, replacement,

or service of coils and other components if necessary.

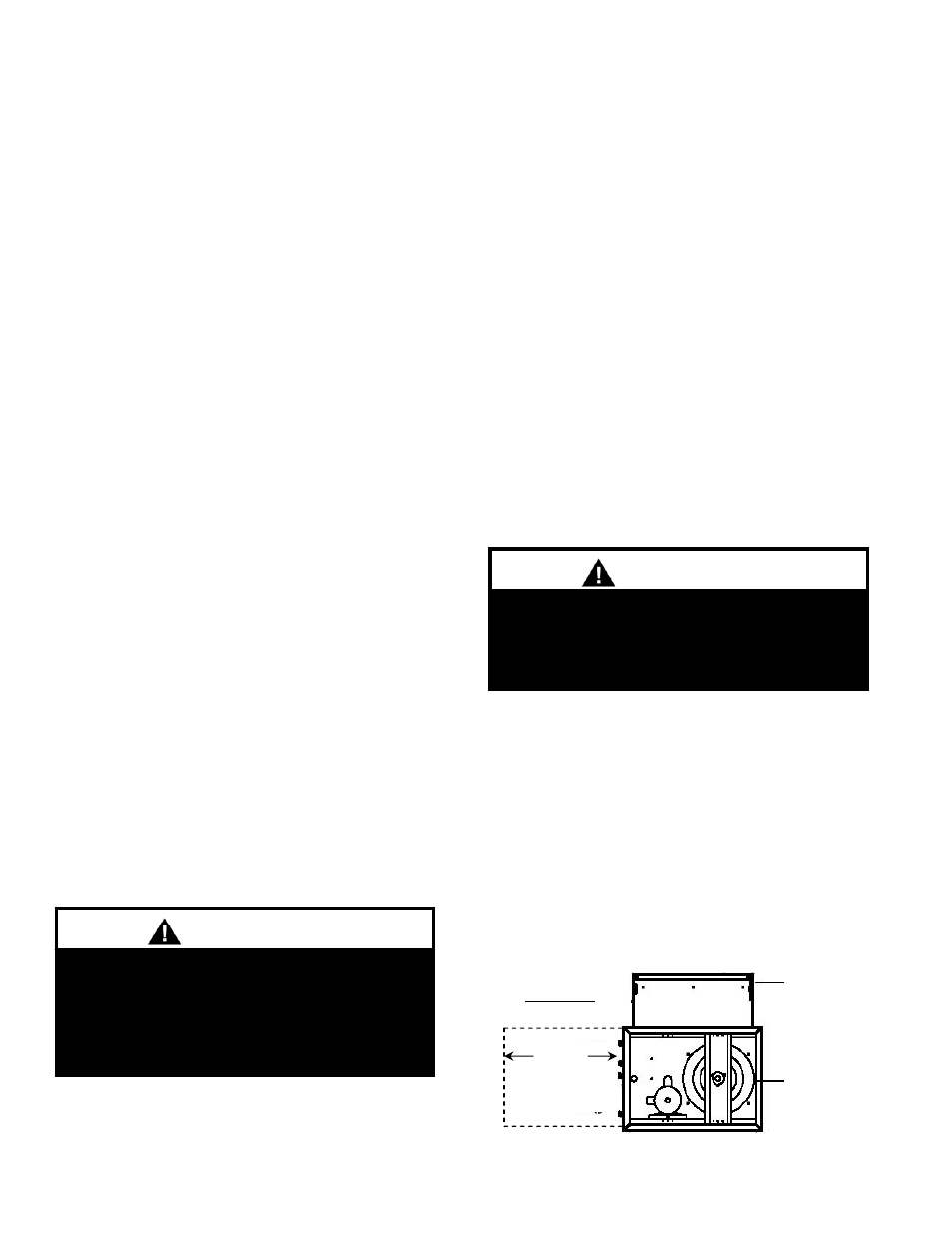

Figure 12a, Service Clearance

36”

Service

Clearance

V2 Top View

Return Air

Collar

Discharge Air

Collar

Always wear hand and eye protection when

handling, installing, servicing, or maintaining

equipment. Sharp or pointed edges, moving parts,

and flying debris may cause personal injury.

WARNING

It is the responsibility of the installing contractor to

comply with codes, ordinances, local and

municipal building laws, and manufacturer’s

instructions. Personal injury and/or equipment

damage may result if proper procedures are not

followed.

WARNING