Pressure diff erential alarm package option – ClimaCool UCR 30, 50 and 70 tons Manual User Manual

Page 61

61

www.climacoolcorp.com

Pressure Diff erential Alarm Package Option

The pressure diff erential alarm option continually monitors

and displays the strainer’s inlet and outlet diff erential

pressure. When the strainer element (conical strainer

basket) becomes signifi cantly clogged, the pressure

diff erential switch-gauge will trigger an audible siren and

a visual fl ashing alarm light. These alarms are intended to

alert maintenance personnel that the strainer element must

be removed and cleaned (See page 59 - Strainer Element

Cleaning).

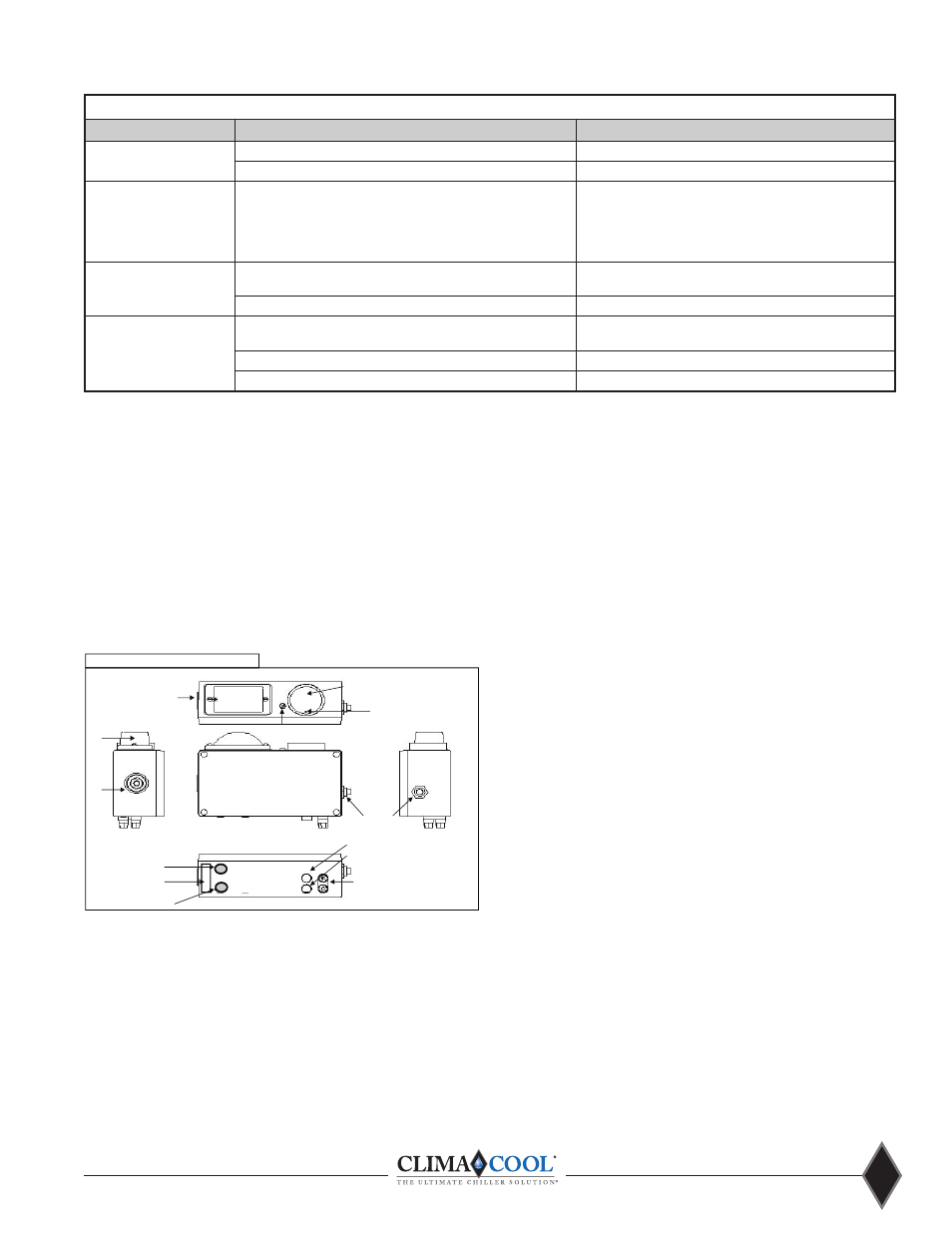

Figure 6

PSID High

PSID Low

PRESSURE DIFFERENTIAL ALARM PACKAGE

Alarm Reset Button

FRONT

VIEW

LEFT SIDE

VIEW

Power To ATF

110 Volt/12 Volt DC

Wall Transformer

Visual

Alarm

Audible

Alarm

Pressure Differential

Switch-Gauge

LED Power Indicator

Differential

Set-Point Contact

Cover-Plate Screw (4) in Corners of

Box (DO NOT REMOVE).

Visual

Alarm

RIGHT SIDE

VIEW

TOP

VIEW

BOTTOM

VIEW

AUX Contacts

(On or Off with Alarm)

Red & Black

Cable Retainer

Operation Instructions

Remove the power supply and insert the connector end into

the socket on the bottom of the PDA housing (See Figure

6 above) and plug the transformer into the power source.

Standard systems are supplied with a 120V power supply to

the primary of the transformer, with an output secondary of

12 VDC. The pressure diff erential switch-gauge is factory set

to 7-8 PSI. The CS strainer operates at a pressure diff erential

slightly less that 1 PSI during maximum fl ow when the

strainer screen is clean. By the time the diff erential pressure

reaches 7-8 PSI, the strainer element will be signifi cantly

clogged and require immediate removal and cleaning. To

adjust the pressure diff erential switch-gauge setting, insert

a 1/16” allen wrench and rotate the diff erential set-point

contact to the desired location (See Figure 6).

Note: We do not recommend setting the diff erential switch-

gauge higher than 10 PSI. Disabling the alarm or increasing

the alarm set point could result in damage to the strainer

element and allow debris to pass into the system.

When the diff erential set point is reached both the audible

and visual alarms will be triggered and will remain engaged

until both the Alarm condition is corrected and the Alarm-

Reset button is pressed. (If the Alarm-Reset button is

pressed but the diff erential pressure is beyond the set point,

the alarms will re-engage immediately). After the strainer

is cleaned and put back in service, the diff erential pressure

should return to 1 PSI.

Auxiliary Contacts

The PDA option is equipped with a remote alarm feature.

The remote alarm contacts are located at the two Black &

Red Banana Clip Posts (See Figure 6). The alarm can be set

up in one of two ways: 1)a remote alarm signal of 12 VDC can

be sent to a central monitoring station or 2) a set of auxiliary

contacts will indicate a “closed” condition when the alarm

activates. (Locate the Auxiliary Contact Schematic inside the

PDA box by removing the four screws on the cover plate).

Water Resistance

The Pressure Diff erential Alarm Controller is water-resistant,

but not water proof. Do not install below ground level

where the box can be submerged in water. Do not remove

the cover plate from the PDA controller. Keep the cover

tightly sealed on the module during normal operation.

TroubleshooƟ ng for ATF Package

Problem

SoluƟ on

• Valve is leaking

past ball

• Seals damaged or worn out

• Install repair kit

• Valve is not stopping at proper closed posiƟ on

• Adjust limit switches

• Valve Stem leaks

• Worn stem seals

• On metal valves: Ɵ ghten stem packing nut 1/2 turn.

CAUTION! Over Ɵ ghtening stem nut could cause drag on

motor and trip internal circuit breaker. May require repair kit

or new valve.

• Valve body leaks

• Loose body bolts or excessive operaƟ on pressure

• Check bolts and observe recommended pressure raƟ ngs

• DefecƟ ve seals

•

Install repair kits or new valve

• Valve hard to turn

• Swollen seals or product buildup in valve chamber

• Check valve for compaƟ bility with product, may require valve

cleaning or new valve

• Valve bolts too Ɵ ght

• Loosen stem nut slightly

• Stem nut too Ɵ ght

• Loosen stem nut slightly