Introduction, Attention installer, General description – ClimaCool UCR 30, 50 and 70 tons Manual User Manual

Page 3: Safety, Danger

3

www.climacoolcorp.com

Introduction

General Description

The UCR confi gurable remote air cooled modular chiller,

The Ultimate Chiller Solution

®

, is designed to provide the

most environmentally friendly, maneuverable, effi

cient,

reliable and serviceable modular chiller in the industry. The

UCR model has the ability to off er a hot gas bypass option

utilizing environmentally friendly R-410A refrigerant for

Green building designs.

Modules are available in 30, 50 and 70 tons, which when

combined can obtain specifi c project turndown and capacity

requirements from 30 to 400 tons per bank.

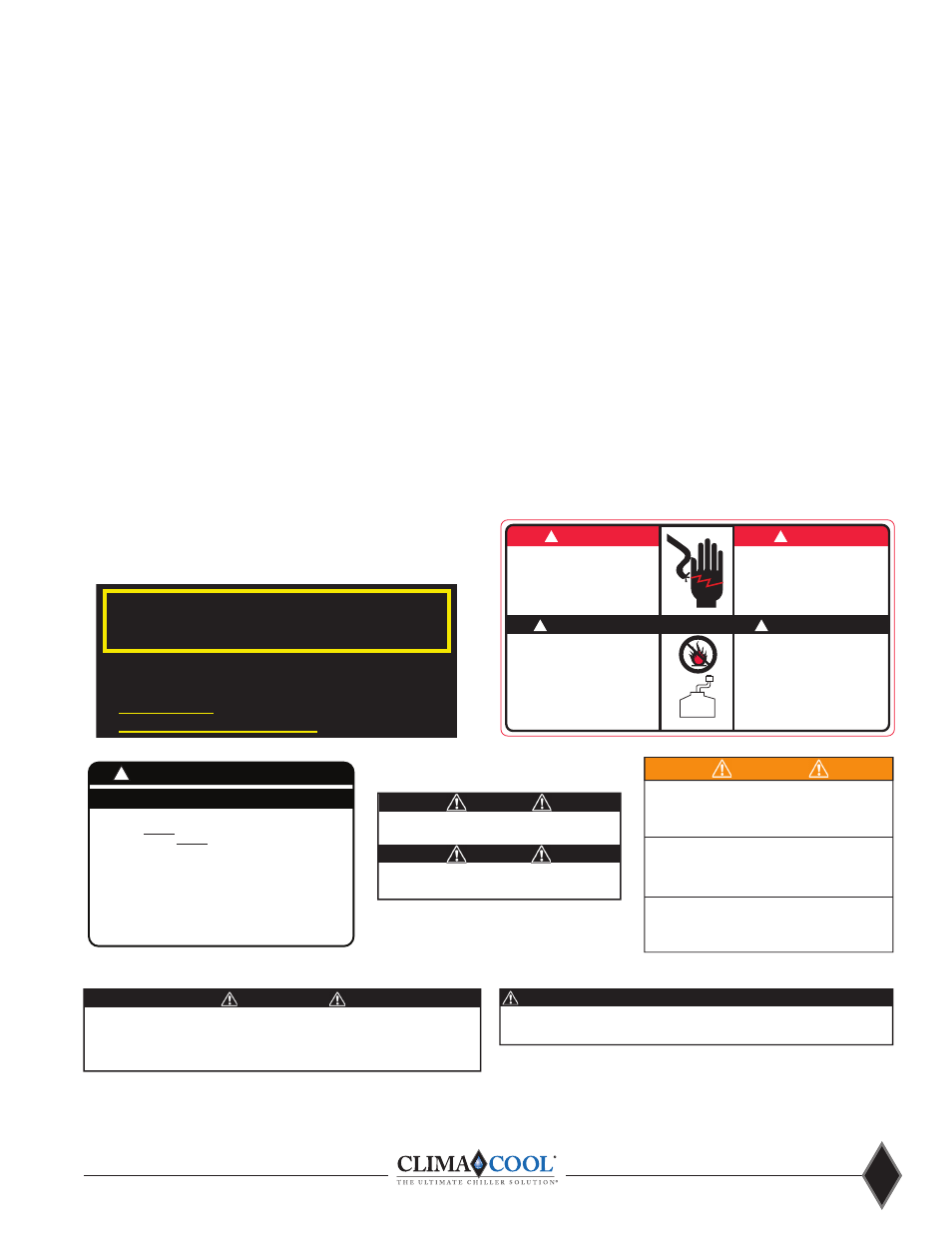

Safety

Throughout this manual warning, danger, caution and

attention notices appear. Read these items carefully before

attempting any installation, service or troubleshooting of

the equipment. All labels on unit access panels must be

observed.

WARNING: Indicates potentially hazardous situation which,

if not avoided, could result in death or serious injury.

DANGER: Indicates an immediate hazardous situation

which, if not avoided, will result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice which, if not avoided, could result in minor

or moderate injury or product or property damage.

ATTENTION: Notifi cation of installed, operation or

maintenance information which important, but which is not

hazard-related.

*(<;065

t &YDFTTJWF$IMPSJOF 6OEJTTPMWFE4PMJETBOE

PUIFSJNQSPQFSXBUFSRVBMJUZDPOEJUJPOT

WILL DAMAGEUIFJOUFSOBMIFBUFYDIBOHFSBOE

WILL VOID YOUR WARRANTY!

DANGER

(OHFWULFVKRFNKD]DUG

0D\UHVXOWLQLQMXU\RUGHDWK

'LVFRQQHFWSRZHUVXSSO\LHV

EHIRUHVHUYLFLQJ

5HIHUVHUYLFLQJWRTXDOLILHG

VHUYLFHSHUVRQQHO

5LVTXHGHFKRFpOHFWULTXH

5pVXOWDWGHPDLGDQVGRPPDJHV

RXODPRUW

'HEUDQFKHUDYDQWGҋHQWUHSUHQGUH

OHGpSDQQDJHGHOҋDSSDUHLO

&RQVXOWHUXQUpSDUDWHXUTXDOLILH

SRXUOHGpSDQQDJH

DANGER

&$87,21

$77(17,21

8QLWWREHVHUYLFHGE\TXDOLILHG

SHUVRQQHORQO\

5HIULJHUDQWV\VWHPXQGHU

SUHVVXUH

5HOLHYHSUHVVXUHEHIRUHXVLQJ

WRXUFK

5HFRYHUUHIULJHUDQWDQGVWRUHRU

GLVSRVHRISURSHUO\

&RQILHUODPDLQWHQDQFHiXQ

WHFKQLFLHQTXDOLILH

/HV\VWpPHIULJRULILTXHVRXV

SUHVVLRQ

'pFRPSULPHUDYDQWGҋH[SRVHUi

ODIODPPH

5pFXSHUpUOHIULJRULJHQHHWOH

VWRFNHURXOHGpWULUH

FRUUHFWHPHQW

RECOVER

REFRIGERANT

WARNING

To avoid the release of refrigerant into the atmosphere,

the refrigerant circuit of this unit must be serviced only by

technicians who meet local, state and federal profi ciency

requirements.

All refrigerant discharged from this unit must be recovered

WITHOUT EXCEPTION. Technicians must follow industry

accepted guidelines and all local, state and federal statutes for

the recovery and disposal of refrigerants.

If a compressor is removed from this unit, system refrigerant

circuit oil will remain in the compressor. To avoid leakage of

compressor oil, the refrigerant lines of the compressor must

be sealed after it is removed.

WARNING

This unit contains HFC-(R410A), an azeotropic mixture of R-32 (Difluoromethane) and R-125 (Pentafluoroethane).

DO NOT VENT HFC-(R410A) to the atmosphere. The U.S. Clean Air Act requires the recovery of any residual

refrigerant. Do not use R-22 service equipment or components on R410A systems.

WARNING!

WARNING! To avoid possible injury or death due to electrical

shock, open the power supply disconnect switch and secure it

in an open position during installation.

CAUTION!

CAUTION! Use only copper conductors for field installed

electrical wiring. Unit terminals are not designed to accept

other types of conductors.

SAFETY WARNING

High voltage is used to operate this equipment. Failure to observe standard electrical safety procedures may result

in serious injury. Only persons qualified and / or properly trained should attempt to install, operate and maintain this

equipment. These chillers come fully charged with refrigerant. Installation, and start – up should be accomplished by

technicians who are fully certified to handle refrigerants, as required by 40 CRF Part 82, subpart F of the Recycling

and Emissions Reduction Act. Scroll compressors are used in this equipment. Phase verification is required for proper

rotation direction. Incorrect rotation will result in elevated sound and internal overload trip failure.

ATTENTION INSTALLER

3 Phase Scroll Compressor Units

t *GUIJTVOJUVTFTB1IBTF4DSPMM$PNQSFTTPS UIFGPMMPXJOH

JOTUSVDUJPOT

MUST BEGPMMPXFE

6OJUQPXFSTVQQMZ

MUST BEXJSFEJOUIFQSPQFSTFRVFODFUPBWPJE

EBNBHFUPUIF1IBTF4DSPMM$PNQSFTTPS

4DSPMM$PNQSFTTPSTXJUI

INCORRECT SPUBUJPOTIPXUIFGPMMPXJOH

DIBSBDUFSJTUJDT

)JHITPVOEMFWFM

)JHITVDUJPOQSFTTVSFBOEMPXEJTDIBHFQSFTTVSF

-PXDVSSFOUESBX

*GBOZPGUIFUISFFBCPWFDIBSBDUFSJTUJDTFYJTU TXBQUXPPGUIF

UISFFTVQQMZXJSFTBUUIFEJTDPOOFDUBOESFDIFDLDPNQSFTTPSGPS

JODPSSFDUSPUBUJPO