3 modifying set dimensions, 4 static & combined modes, 2 measurement result – CEMB USA C71_2 SE evo (B) User Manual

Page 12

12

FI

FE

Use and maintenance manual Rev. 10-2011

ENGLISH

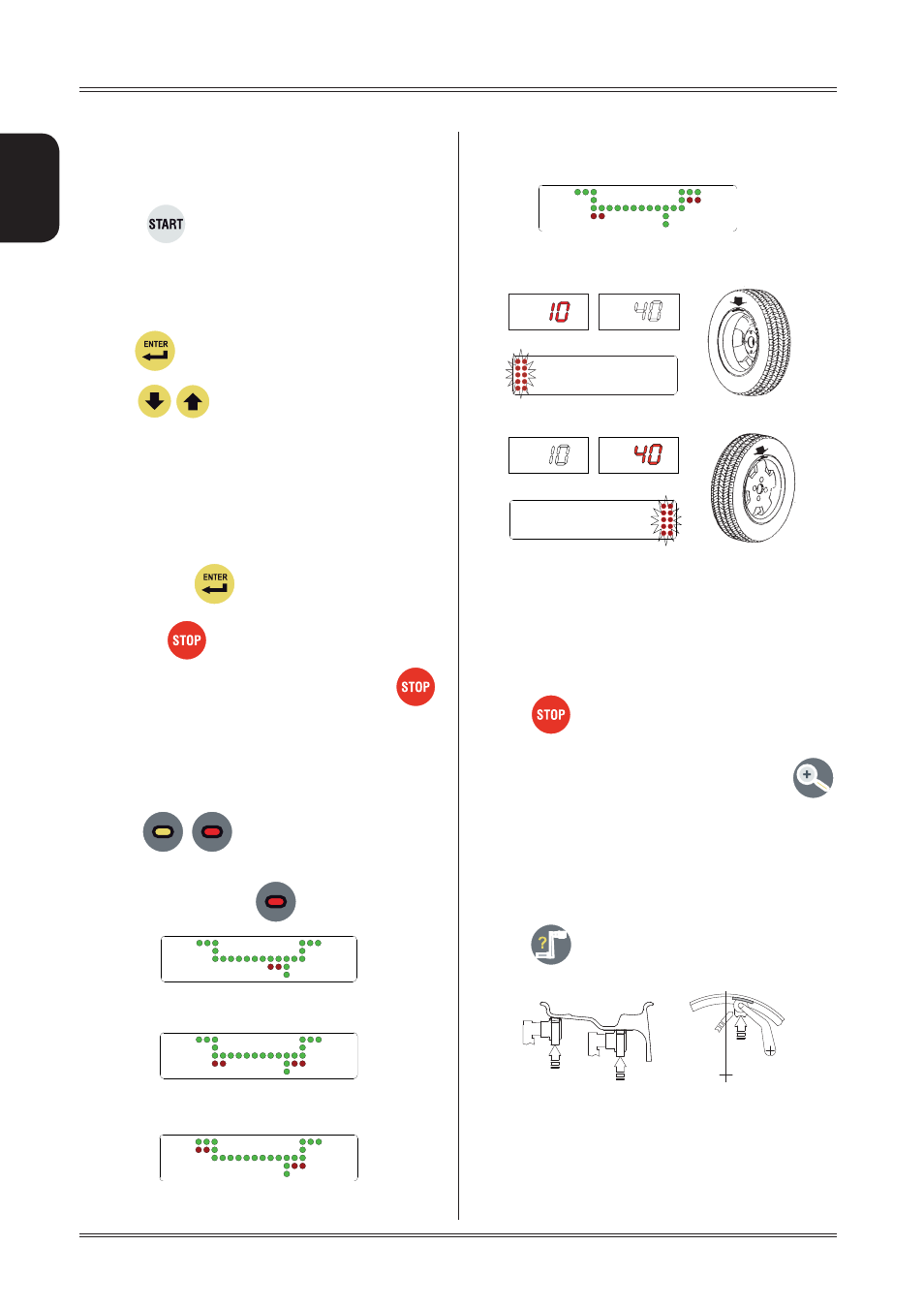

Slowly close the wheel guard until a “beep” is heard.If

“AUTOMATIC START” is enabled when the guard is closed,

the balancing machine performs a cycle to measure the

imbalance, otherwise the width value just acquired is shown.

Press the

button to perform a spin.

5.1.3 Modifying set dimensions

If the wheel dimensions have been entered incorrectly,

the parameters can be modified without repeating the

balancing spin by pressing for 2 seconds :

access parameter modifi cation

→

(select

to modify: (a) distance, (b) width, (d)

diameter

In the case of standard weights:

(a)distance,(b)width,(d)diameter

In the case of adhesive weights:

(a1) inside distance,(a2) outside distance,(d1) inside

diameter,(d2) outside diameter

press

to select (a) (b) or (d)

→

to recalculate the unbalance

or:

pull out the gauge to repeat the measurement

→

to obtain the new measurement.

5.1.4

Static & combined modes

After calibration as per

PRESETTING OF WHEEL DIMENSIONS

,

it is possible to modify the position of the correction weights

using the

buttons.

STATIC: Select by pressing

(5E)

Balancing of light alloy rims with application of adhesive

weights on the shoulders of the rims.

Combined balancing: adhesive weight on the outside and

clip-on weight on the inside.

Combined balancing: adhesive weight on the inside and

clip-on weight on the outside.

5.2 MEASUREMENT

RESULT

After performing a balancing spin, the amounts of unbal-

ance are shown on the digital readouts. The illuminated

LEDs 3 and 4 indicate the correct angular position of the

wheel to mount the counterweights (12 o’clock). If the

wheel clamp option is enabled (see

MENU

), the wheel is

automatically clamped in the correction position.

Pressing

the spindle can be locked/released in any

position to facilitate mounting the wheel (see

MENU

).

For unbalance within tolerance 0 (zero); using

values within tolerance can be viewed.

5.3 EXACT POSITIONING OF THE ADHESIVE

WEIGHT BY MEANS OF THE GAUGE WITH

CLIPS

P

▪

ress

if using the correction method with adhe-

sive weights on the inside of the rim

Fit the correction weight in the specific gauge seat with

▪

the adhesive part facing upwards

Bring the wheel into correct angular position for the

▪

plane to be corrected

If the wheel clamp option is enabled (see

▪

MENU

),the wheel

is automatically clamped in the correction position.

withdraw the gauge until the correction plane indication

▪

arrows turn green

Use of the wheel balancer