6 - set up – CEMB USA C71_2 (A) User Manual

Page 12

START

START

START

STOP

I 0439 -

12

GB

Initial unbalance

phase shift

Possible approximations

residual static

r

esidual static

residual static

Choice with minimum

static residual

With conventional

wheel balancer

residual static

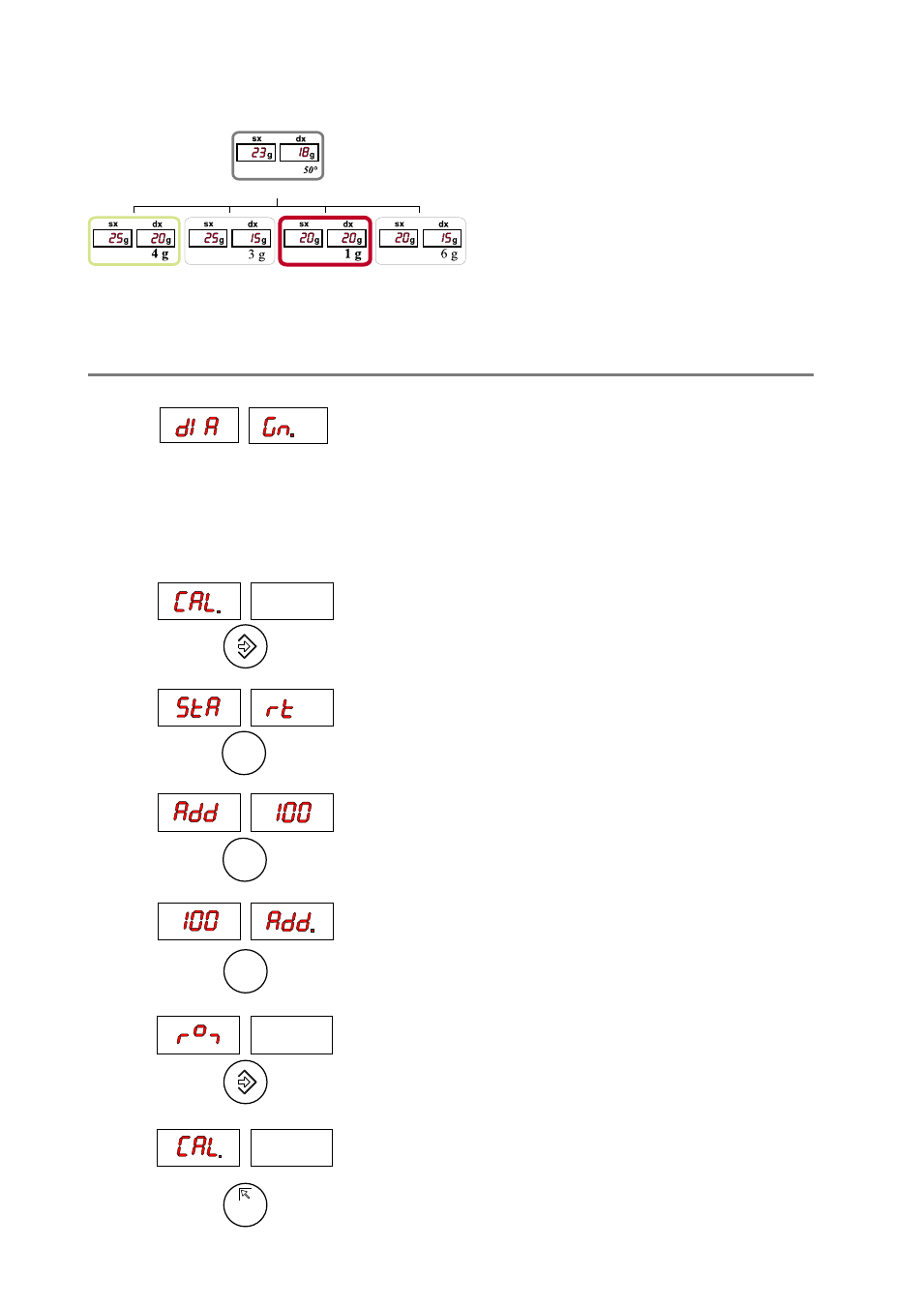

5.8 - Automatic minimization of static unbalance

This program is designed to improve the quality of

balancing without any mental effort or loss of time by

the operator. In fact by using the normal commercially

available weights, with pitch of 5 in every 5 g, and by

applying the two counterweights which a conventional

wheel balancer rounds to the nearest value, there could

be a residual static unbalance of up to 4 g. The damage

of such approximation is emphasized by the fact that

static unbalance is cause of most of disturbances on

the vehicle. This new function, resident in the machine,

automatically indicates the optimum entity of the

weights to be applied by approximating them in an

“intelligent” way according to their position in order to

minimize residual static unbalance.

6 - Set up

6.1 - Autodiagnostics

performs tests useful for maintenance staff

6.2 - Autocalibration

For autocalibration proceed as follows:

- Fit a wheel with steel rim of average dimensions on the shaft. Example 6” x 14” (± 1”)

- Set the exact dimensions of the wheel mounted.

CAUTION !! Setting incorrect dimensions will result in the machine not being properly calibrated and hence all the

subsequent measurements will be incorrect until a new autocalibration is performed with the correct

dimensions!!

N.B.: Use steel wheel rims detection from “

MANUAL DIMENSION PRESETTING

”.

- Perform a spin under normal conditions.

- Add a 100 g. sample weight (3.5 oz) on the outside in any angular

position.

- Shift a 100 g sample weight from the outside to the inside keeping

the same angular position.

- Turn the wheel until the 100 g weight is in the 12 o’clock position.

END OF AUTOCALIBRATION

CANCEL AUTOCALIBRATION IN ANY PHASE.