8 - routine maintenance – CEMB USA C72_2 (A) User Manual

Page 27

I 0459 -

27

GB

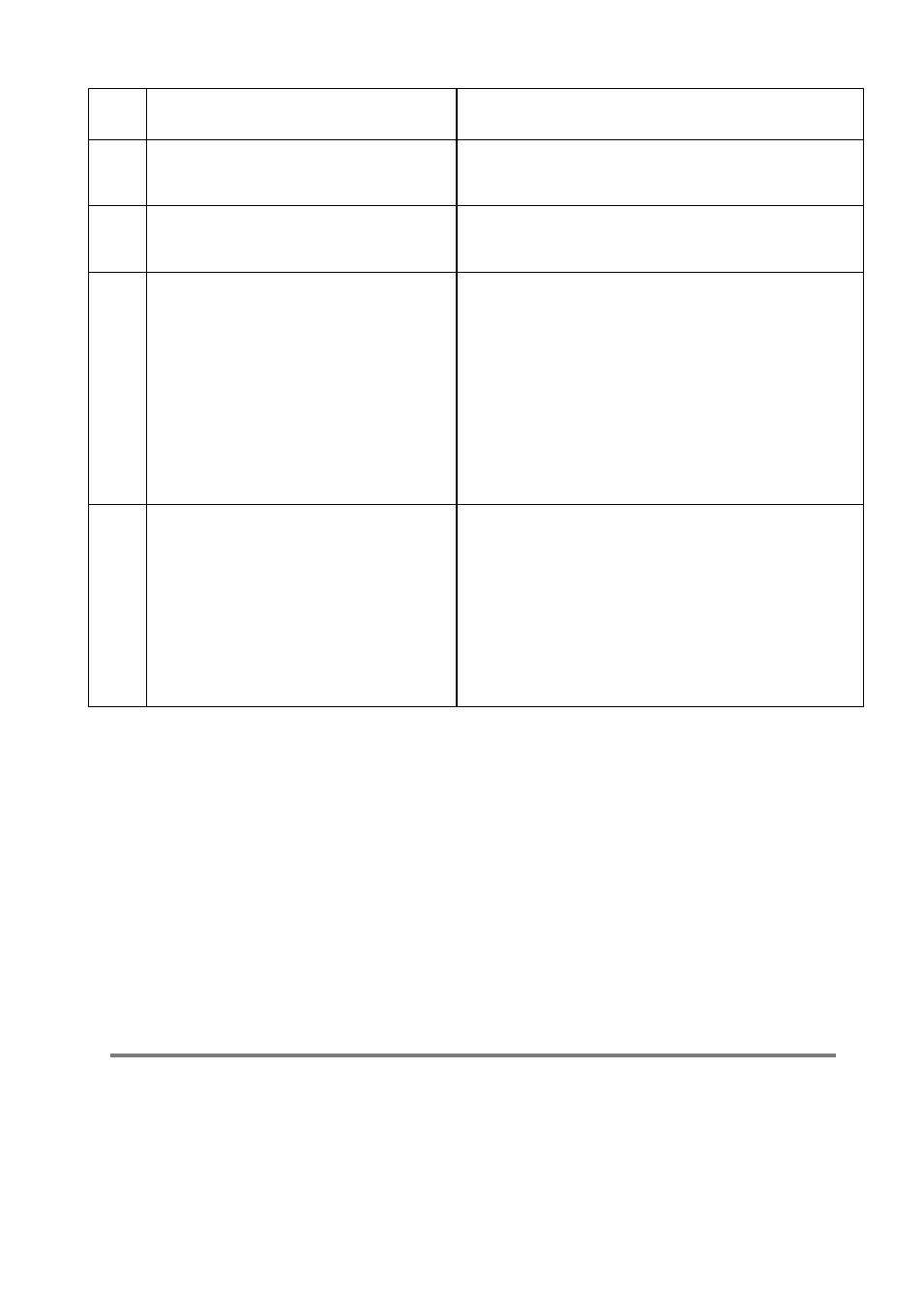

Err. 20

Wheel at standstill. The wheel is at a standstill for

more than one second after START.

1. Check functioning of the phase generator.

2. Check the connections on the power board.

3. Replace the computer board.

Err. 24

Distance between the spokes smaller

than 18 degrees.

1. The minimum distance between the spokes where to split the

unbalance must be greater than 18 degrees

2. Repeat the SPLIT function increasing the distance between the

spokes.

Err. 25

Distance between the spokes greater

than 120 degree

1. The minimum distance between the spokes where to split the

unbalance must be smaller than 120 degrees

2. Repeat the SPLIT function increasing the distance between the

spokes.

Err.54

Sonar readout error.

Sonar value readout impossible.

1. Position the eccentricity measurement sonar correctly before

performing the measurement.

2. Check eccentricity sonar connections.

3. Check the power supplies on the power card.

4. Replace the eccentricity measurement sonar.

5. Make sure that the wheel does not halt before completing at least

4/5 revolutions after the first braking impulse.

6. Verify belt tautness.

7. Replace the computer board.

Err.55

Sonar readout error.

Sonar values are insufficient for correct measurement

of eccentricity.

1. Position the eccentricity measurement sonar correctly before

performing the measurement.

2. Make sure that the wheel does not halt before completing at least

4/5 revolutions after the first braking impulse.

3. Verify belt tautness.

4. Mount a wheel of medium dimensions (14”x5 ¾”) and perform an

eccentricity measurement . If in these conditions error 55 no longer

occurs, this means that the wheel inertia causing the problem is

such as to half the wheel before having acquired the minimum

number of values necessary for reliable eccentricity measurement.

7.1 - Inconsistent unbalance readings

Sometimes after balancing a wheel and removing it from the balancing machine, it is found that, upon mounting it on

the machine again, the wheel is not balanced.

This does not depend on incorrect indication of the machine, but only on faulty mounting of the wheel on the adapter;

i.e. in the two mountings, the wheel has assumed a different position with respect to the balancing machine shaft

centre line. If the wheel has been mounted on the adapter with screws, it could be possible that the screws have not

been correctly tightened, i.e. crosswise one by one, or else (as often occurs) holes have been drilled on the wheel

with too wide tolerances.

Small errors, up to 10 grams (0.4 oz) are to be considered normal in wheels locked by a cone; the error is normally

greater for wheels fastened with screws or studs.

If, after balancing, the wheel is found to be still out-of-balance when refitted on the vehicle, this could be due to

the unbalance of the car brake drum or very often due to the holes for the screws on the rim and drum sometimes

drilled with too wide tolerances. In such case a readjustment could be advisable using the balancing machine with

the wheel mounted.

8 - Routine maintenance

Switch off the machine from the mains before carrying out any operation.

8.1 - To replace the fuses

The power supply board, accessible from the rear by removing the rear cover, is fitted with safety fuses (see

Exploded Drawings). If fuses require replacement, use ones of the same current rating.

If the fault persists, contact the Technical Service Department.

NONE OF THE OTHER MACHINE PARTS REQUIRE MAINTENANCE.