Gb 5.7 - unbalance optimization, 8 - automatic minimization of static unbalance – CEMB USA C72_2 (A) User Manual

Page 17

I 0459 -

17

sx

g

g

dx

50°

sx

g

g

dx

4 g

3 g

1 g

6 g

sx

g

g

dx

sx

g

g

dx

sx

g

g

dx

GB

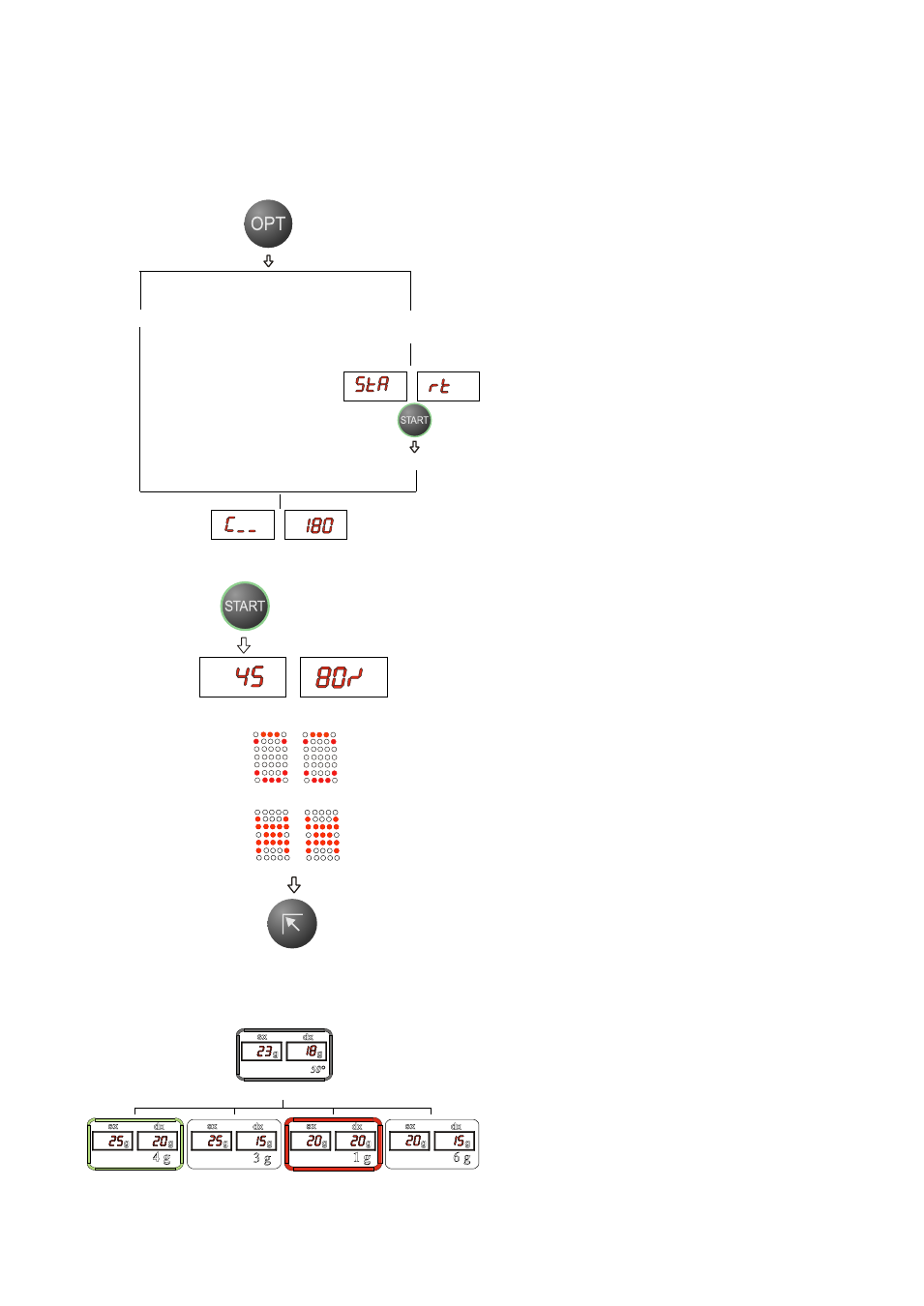

5.7 - Unbalance optimization

- This function serves to reduce the amount of weight to be added in order to balance the wheel.

- It is suitable for static unbalance exceeding 30 g.

- It improves the residual eccentricity of the tyre.

- Mark with chalk a reference point on the adapter and rim.

- With the aid of a tyre remover, turn the tyre on the rim by

180°.

- Refit the wheel with the reference mark coinciding between

rim and adapter.

- RH display: percentage reduction

- LH display: actual static unbalance which can be reduced

by rotation.

- Mark the two positions of the rim and tyre, and turn the

tyre on the rim until the positions correspond in order to

obtain the optimization on the display.

RETURN TO MEASUREMENT SCREEN.

TYRE

POSITION

RIM

POSITION

Unbalance already measured

No previous unbalance

measurement

unbalance measurement

5.8 - Automatic minimization of static unbalance

This program is designed to improve the quality of

balancing without any mental effort or loss of time by

the operator. In fact by using the normal commercially

available weights, with pitch of 5 in every 5 g, and by

applying the two counterweights which a conventional

wheel balancer rounds to the nearest value, there

could be a residual static unbalance of up to 4 g. The

damage of such approximation is emphasized by the

fact that static unbalance is cause of most of distur-

bances on the vehicle. This new function, resident

in the machine, automatically indicates the optimum

entity of the weights to be applied by approximating

them in an “intelligent” way according to their position

in order to minimize residual static unbalance.

Initial unbalance

phase shift

Possible approximations

residual static

residual static

residual static

residual static

With conventional

wheel balancer

Choice with minimum

static residual