Diagnostics – CEMB USA C29 User Manual User Manual

Page 13

13

Use and maintenance manual Rev. 04-2010

ENGLISH

7. Diagnostics

7.1 INCONSISTENT

UNBALANCE

READINGS

In some cases, when a wheel that has just been balanced

is repositioned on the balancer, the machine can detect

an unbalance.

This is not a machine problem but is due to faulty mounting

of the wheel on the flange. In other words, when mount-

ing the wheel after initial balancing, it has taken another

position with respect to the balancer shaft axis.

If the wheel has been mounted on the flange with screws,

the screws may not have been tightened correctly (criss-

cross sequence) or the tolerances of the holes drilled in

the wheel may be too large. Small errors, up to 10 grams

(4 oz), are to be considered normal in wheels locked with

the relative cone: The error is normally greater for wheels

locked with screws or studs.

If, after balancing, the wheel is still unbalanced when re-

fitted on the vehicle, this could be due to an unbalanced

brake drum or, very often, the tolerances of the holes

drilled in the rim and drum are too large. In this case,

balancing should be performed using a balancer with the

wheel mounted on the vehicle.

7.2 ALARM

SIGNAL

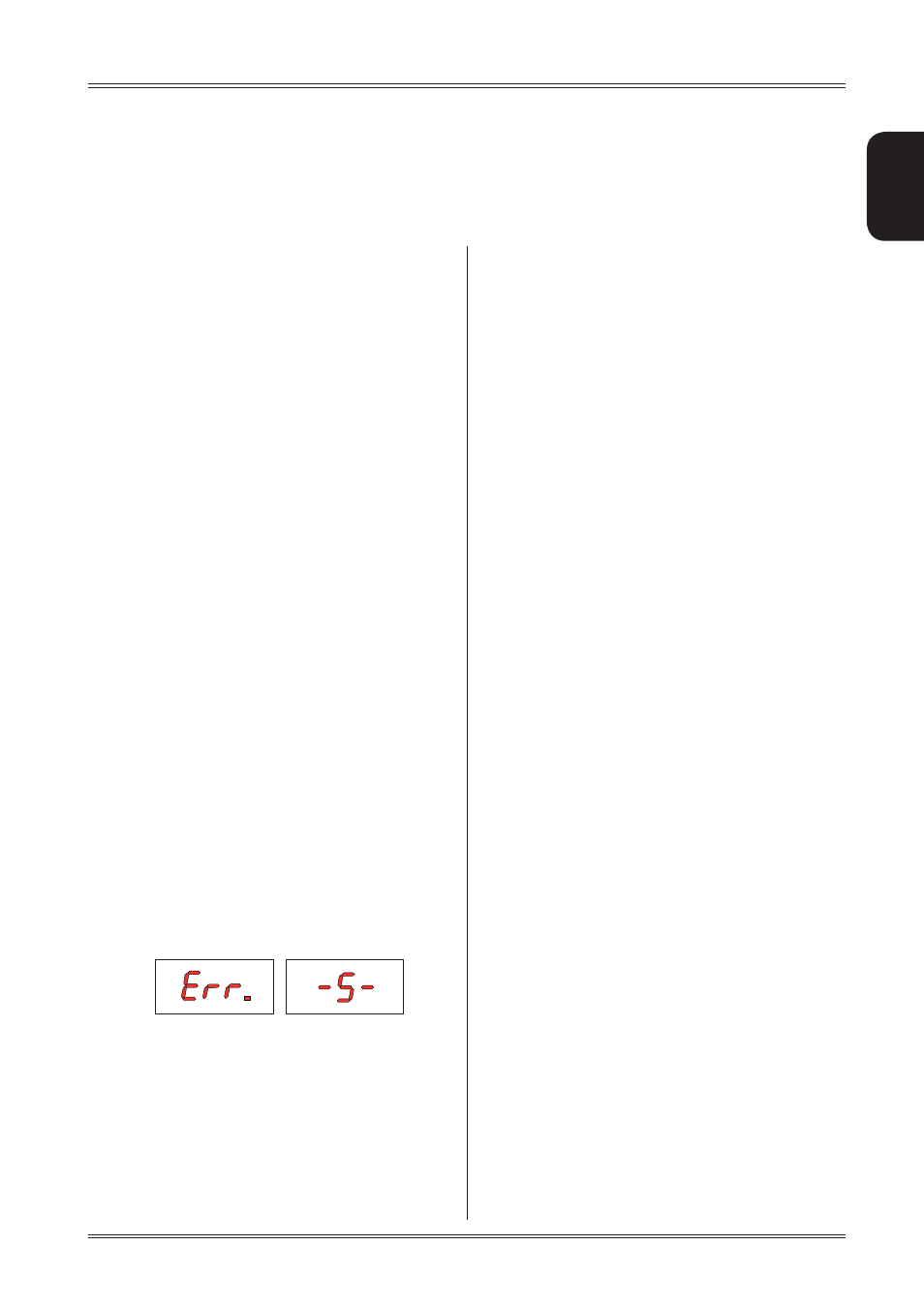

The machine has a self-diagnostics cycle which identi-

fies the most frequent malfunctions during the normal

work cycle.

These malfunctions are processed by the system and

shown on the display.

Diagnostics