Drill feed rate adjustment, Pilot drill depth adjustment – Castle TSM-21 Serial 61064 and lower (Mead) Operator Manual User Manual

Page 9

Drill Feed Rate Adjustment

The speed the machine drills the pilot hole is set at the factory. This is a function of the air

pressure set at the internal air regulator.

The drill feed rate will be best when the air pressure is set at 85psi.

Normally you won’t need to adjust the regulator. However, if your drill cycle slows

down significantly over time an increase in the regulator setting will correct the situation.

Do not increase air pressure beyond 85psi. You can check this by putting a pressure

gauge on the line to the clamp cylinder and cycling the machine without stock in place

and the motors off.

Pilot Drill Depth Adjustment

The pilot drill operation works best when the drill depth is adjusted so that the drill bit just barely

breaks into the pocket. If the drill bit extends farther than is necessary, it could cause shorter bit

life.

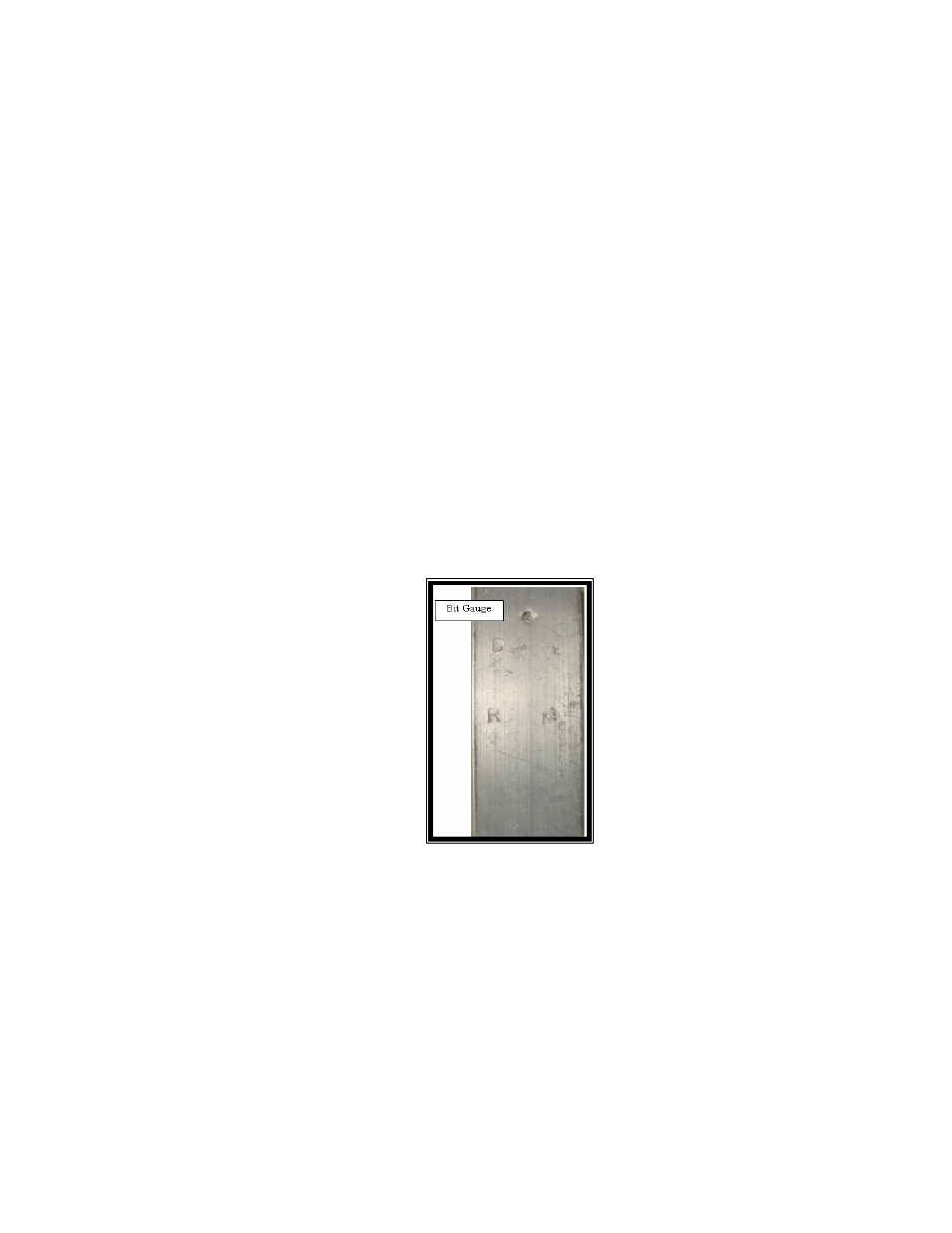

Figure 5

The drill bit setting is determined with the Bit Gauge (Figure 5), included with your

machine.

To use, simply set the plate on top of the collet and use an awl to scratch a reference line

in the soft aluminum where each bit should be. (Figure 6)

7