Schreiber Chillers 1000AC-MRI User Manual

Page 22

2.3.2. Place unit in position on wedges located at

four points (two below approximate center of driver

and two below approximate center of pump). Adjust

wedges to level unit. Level or plumb suction and

discharge flanges.

2.3.3. Make sure bedplate is not distorted and final

coupling alignment can be made within the limits of

movement of motor and by shimming, if necessary.

2.3.4. Tighten foundation bolts finger tight and build

dam around foundation. Pour grout under bedplate

making sure the areas under pump and motor feet

are solid. Allow grout to harden 48 hours before

fully tightening foundation bolts.

2.3.5. Tighten pump and motor hold-down bolts

before connecting the piping to pump.

3.1. Low static suction lift and short, direct, suction piping is

desired. For suction lift over 10 feet and liquid temperatures

over 120 F, consult pump performance curve for Net Positive

Suction Head Required.

3.2. Suction pipe must be as large as the suction connection

of the pump. Smaller size will degrade performance.

3.3. If larger pipe is required, and eccentric pipe reducer (with

straight side up) must be installed at the pump.

3.4. Installation with pump below source of supply:

3.4.1. Install full flow isolation valve in piping for

inspection and maintenance.

CAUTION

Do not us e suction isolation valve to throttle pump.

3.5. Installation with pump above source of supply:

3.5.1. Avoid air pockets. No part of piping should be

higher than pump suction connection. Slope piping

upward from liquid source.

3.5.2. All joints must be airtight.

3.5.3. Foot valve to be used only if necessary for

priming, or to hold prime on intermittent service.

3.5.4. Suction strainer open area must be at least

triple the pipe area.

3.6. Size of the inlet from liquid source and minimum

submergence over inlet, must be sufficient to prevent air from

entering pump through vortexing. See figs. 2-5.

4.1. Arrangement must include a check valve located

between a gate valve and the pump. The gate valve is

for regulation of capacity, or for inspection of the pump

or check valve.

4.2. If an increaser is required, place between check

valve and pump.

4.3. Use 3-4 wraps of Teflon tape to seal threaded

connections.

5.1. Close-coupled Units:

5.1.1. No field alignment necessary.

5.2. Frame-Mounted Units:

5.2.1. Even though the pump-motor unit may

have a factory alignment, this could be

disturbed in transit and must be checked prior

to running.

5.2.2 Tighten all hold-down bolts before

checking the alignment.

5.2.3. If re-alignment is necessary, always

move the motor. Shim is required.

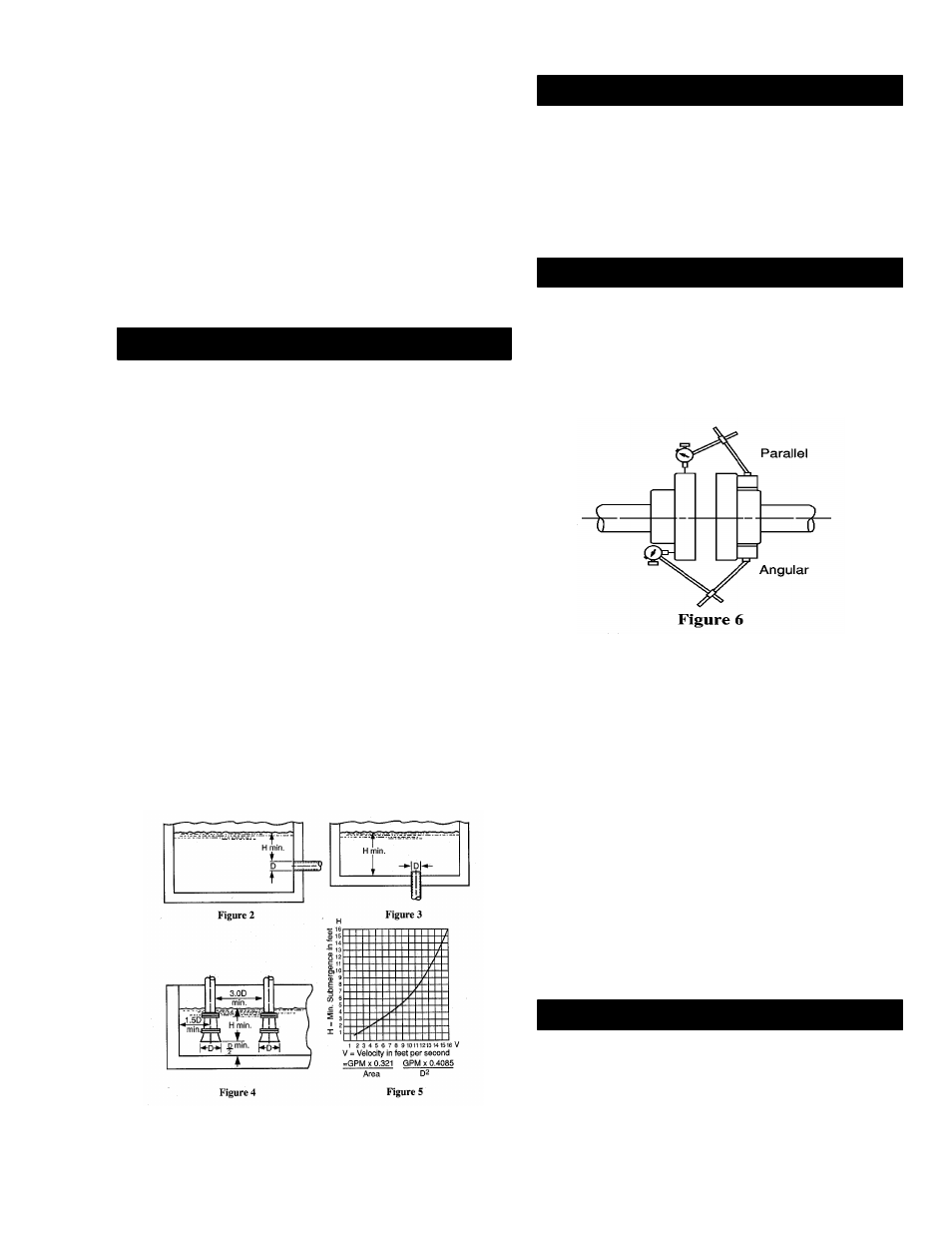

5.2.4. Parallel misalignment – shafts with axis

parallel but not concentric. Place a dial

indicator on one hub and rotate this hub 360°

while taking readings on the outside diameter

of the other hub. Parallel alignment occurs

when Total indicator reading is .005”, or less.

5.2.5. Angular misalignment – shafts with axiz

parallel but not concentric. Place dial

indicator on one hub and rotate this hub 360°

while taking readings on the face of the other

hub. Angular alignment is achieved when

Total Indicator Reading is .005”, or less.

5.2.6. Final alignment is achieved when

parallel and angular requirements are

satisfied with motor hold-down bolts tight.

CAUTION

Always recheck both alignments after making any

adjustment.

6.1. Correct rotation is right-hand (clockwise when

viewed from the motor end). Switch power on and off

quickly. Observe shaft rotation. To change rotation:

3. Suction Piping:

4. Discharge Piping:

5. Motor-To-Pump Shaft Alignment:

6. Rotation:

16