Conveyor tension setting, General information, Conveyor re-tensioning – DE-STA-CO Precision Link Conveyors 1.5, 3.0, 4.5, 6.0 Table Top; 6.0, 9.0 Heavy Duty User Manual

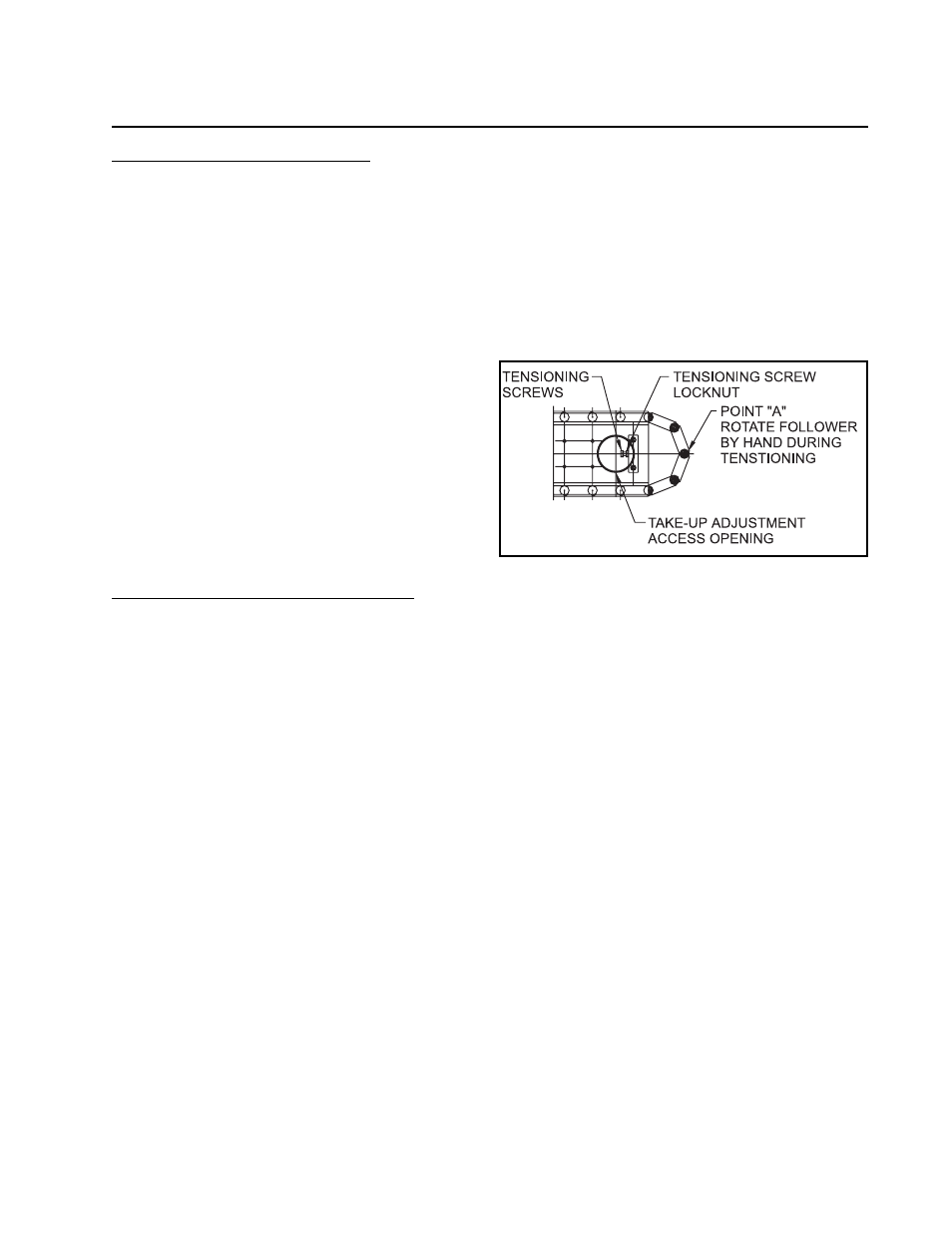

Page 9: Fig. 2. conveyor re-tensioning

CONVEYOR TENSION SETTING

GENERAL INFORMATION

To maintain and guarantee accuracy and

performance of the conveyor, CAMCO utilizes a

unique “chordal action compensating CAM”.

This CAM arrangement is state of the art in

precision link conveyor design. Spring actuated

tensioned conveyors utilizing either tail shaft or

secondary tensioning were rejected by CAMCO

because of the contribution to indexing inaccu-

racies.

Once the conveyor is properly tensioned at the

factory, no further adjustment is required in the

field for the duration of expected follower lift.

We are including instructions for adjustments,

should it become necessary to replace follow-

ers, or if the tension is lost because of extraordi-

nary conditions (i.e., EXTREME THERMAL

EXPANSION). It is recommended that CAMCO

factory be consulted prior to starting with the

actual adjustment. Failure to do so may void all

warranties for the conveyor.

CONVEYOR RE-TENSIONING

1. Read section in general information regard-

ing warranty.

2. Remove the radial guides at the take-up

end of the conveyor.

3. Loosen the take-up cam locking screws (4

per side) located in slotted holes in the main

frame portion of the conveyor. These are

located on both sides of the fitted key

section of the take-up cam.

The slots should be obvious on both sides

of the “over and under” conveyor. The slots

should be obvious on the top of the “carou-

sel” conveyor but may be more difficult to

locate on the bottom due to the base

mounting.

If a pedestal mount is used, the four

"forward-most” screws used to mount the

base to the main frame will be the take-up

cam locking screws.

On a heavy duty base design, clearance

holes will be provided to locate and access

these screws. It may also be necessary, on

a heavy duty base, to loosen the three end

support block mounting screws, located on

the bottom of the conveyor frame at the

extreme end.

4. Once the locking screws have been loos-

ened, remove the round access cover for

the tension adjusting screw. Refer to

Figure 2.

Fig. 2. Conveyor re-tensioning.

5. Hand crank the index drive input reducer

until a link pin follower is positioned at the

high point of the take-up cam (point “A” as

shown in Figure 2).

6. Slowly tighten the tensioning screws, an

equal amount, until it becomes impossible to

turn the link pin cam follower, at point “A”, by

hand. At this point, it will still be easy to turn

the follower using pliers. If it is difficult with

pliers, you have overtightened.

7. Be sure that the followers at both ends of

the link pin have approximately. the same

loading. It is important to adjust the take-up

screws equally.

8. Tighten locknuts and locking screws (4 per

side).

9. Re-install the radial covers and tension

screw access cover.

8