Changing of precision link cam followers, Link pin followers (see pages 12 to 15), Link support followers – DE-STA-CO Precision Link Conveyors 1.5, 3.0, 4.5, 6.0 Table Top; 6.0, 9.0 Heavy Duty User Manual

Page 7: Fig. 1. removing link

CHANGING OF PRECISION LINK CAM FOLLOWERS

The changing of cam followers on CAMCO

Precision Link Conveyors is done by two meth-

ods, depending upon which follower is worn.

The procedure for changing the link pin follow-

ers (3) is different from the procedure for the

link support followers (10). (See Pages 12 to

15).

The following will describe the steps required

for each procedure:

LINK PIN FOLLOWERS

(See Pages 12 to 15)

1. Remove the radial guides from the drive

end of the conveyor.

2. Index the conveyor until the worn link pin

followers (3) are exposed at the end of the

conveyor.

3. Remove the retaining ring (4) holding

follower (3) on pin (2).

4. Remove the worn or damaged follower (3)

and replace.

CAUTION:

If shims (5) are used between

the link (9) and follower (3),

be sure to replace before

installing new follower.

5. Repeat until all worn or damaged followers

are replaced.

LINK SUPPORT FOLLOWERS

1. Remove the radial guides at the take-up

end of the conveyor.

2. Loosen the take-up cam locking screws (4

per side) located in slotted holes in the main

frame portion of the conveyor. These are

located on both sides of the fitted key

section of the take-up cam.

The slots should be obvious on both sides

of the “over and under” conveyor. The slots

should be obvious on the top of the “carou-

sel” conveyor but may be more difficult to

locate on the bottom due to the base

mounting.

If a pedestal mount is used, the four

"forward-most” screws used to mount the

base to the main frame will be the take-up

cam locking screws.

On a heavy duty base design, clearance

holes will be provided to locate and access

these screws. It may also be necessary, on

a heavy duty base, to loosen the three end

support block mounting screws, located on

the bottom of the conveyor frame at the

extreme end.

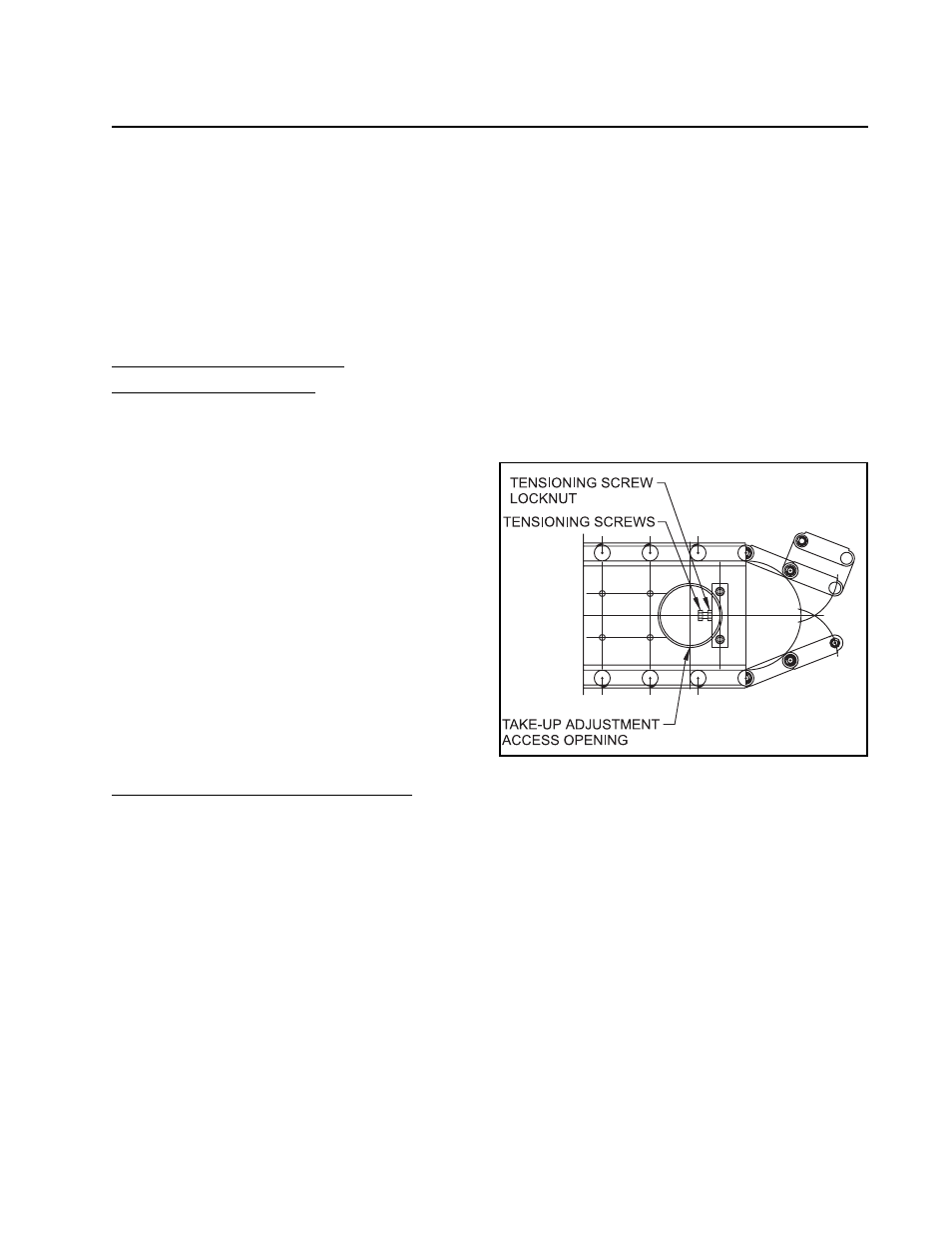

3. Once the locking screws have been loos-

ened, remove the round access cover for

the tension adjusting screw and back off the

tensioning screws two turns. Refer to

Figure 1.

Fig. 1. Removing link.

4. At this time, it will be possible to force the

take-up end towards the drive end enough

to provide slack in the link chain.

5. Hand crank the index drive input reducer

until the suspect link is positioned on the

radial end of the take-up cam.

6. Remove retaining rings (4) on the link pins

of the link to be removed.

6