BVA Hydraulics P350, P601S, P1000, P1000AD, P2001 User Manual

Page 4

BEFORE USE

1. Before using this product, read the instruction manual completely and familiarize

yourself thoroughly with the product, its components and recognize the hazards

associated with its use.

2. Verify that the product and the application are compatible. Inspect before each

use. Do not use if bent, broken, leaking or damaged components are noted.

3. Replace worn or damaged parts and assemblies with BVA Hydraulics Authorized

Replacement Parts only (See Replacement Parts Section). Lubricate as

instructed in Maintenance Section.

4. Ensure method of confirming load is accurate and working properly. Have gauge

or load cell accuracy verified by qualified personnel on a yearly basis.

5. Pumps should be stored where protected from the elements, abrasive dust,

and damage. Pumps can be stored horizontally or vertically.

SETUP

1. Prepare the pump for use:

A) For Models P350, P1000 & P1000AD:

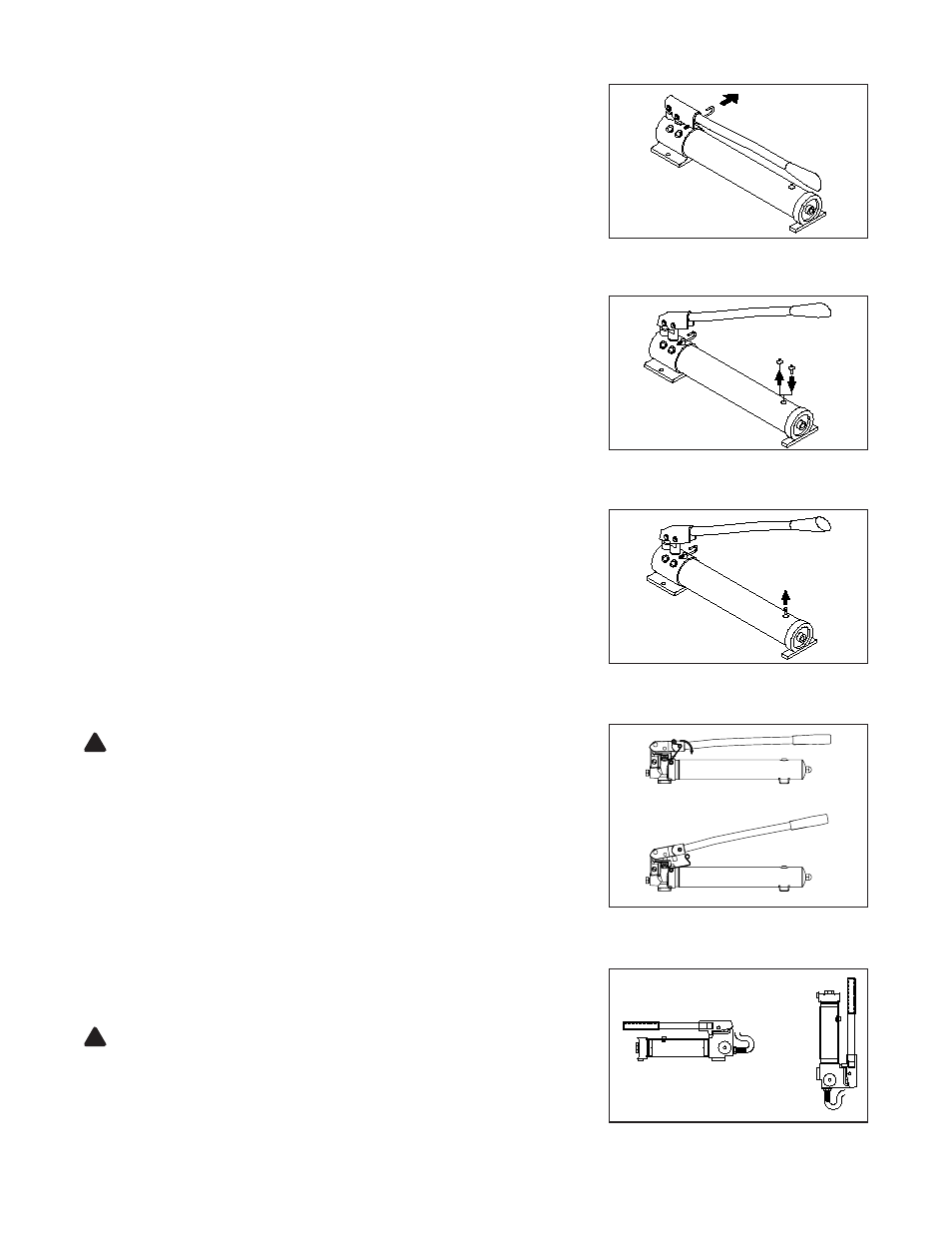

• Pull spring loaded lock pin, pivot toward rear to unlock the handle (Fig. 5).

• Remove shipping plug and replace with air vent plug (Fig. 6).

• Pull vent plug stem upward before use, press down when moving or storing

the pump (Fig. 7).

B) For Model P601S:

• Push the handle lock latch to unlock the pump handle (Fig. 8).

C) For Model P2001:

• Pull spring loaded lock pin pivot toward rear to unlock the handle (Fig. 5).

2. Carefully remove the threaded plug from oil outlet port.

3. Connect coupler, fitting or hose of matching threads. Install in-line pressure

gauge.

NOTICE: Use an approved, high-grade pipe sealant to seal all hydraulic

connections

4. Check for leaks in system and have repaired by qualified personnel as needed.

Before repairs are made, depressurize system by opening the release valve

counterclockwise, but no more than 2 full turns.

OPERATION

WARNING: ALWAYS monitor pressure, load or position using suitable

equipment. Pressure may be monitored by means of an optional manifold

and gauge. Load may be monitored by means of a load cell and digital

indicator. Correct application position can only be determined by the operator

of the equipment.

1. Connect the pump to suitable application.

2. Ensure the oil level is correct and the system fittings and connections are leak

free before operating the pump.

3. Pump may be used in horizontal and vertical position

as illustrated on Figure 9.

4. Close release valve by turning it clockwise. Finger tight ONLY. Using tools on

release valve can damage it and cause the pump to malfunction.

5. Pump handle until desired pressure, load or position is reached.

6. Pressure will maintain until the release valve is opened.

7. To retract application, turn the release valve knob slowly counterclockwise

(never more than 2 full turns).

WARNING: NEVER operate pump with release valve closed and

disconnected from application. If operated in this condition, the hose and

connections become pressurized. This increases burst hazard. Damage

may occur to pump and its components.

4

Figure 6 - Remove shipping plug and

replace with air vent plug before initial use.

Figure 7 - Pull stem upward before use,

press down when moving or storing pump.

Figure 8

- Push the handle lock latch to

unlock the pump handle.

Figure 5 - Pull spring loaded lock pin, pivot

toward rear to unlock pump handle.

Figure 9 - Horizontal and Vertical Position

!

!

a)

b)