Maintenance, Troubleshooting guide – BVA Hydraulics HPD1610 User Manual

Page 5

5

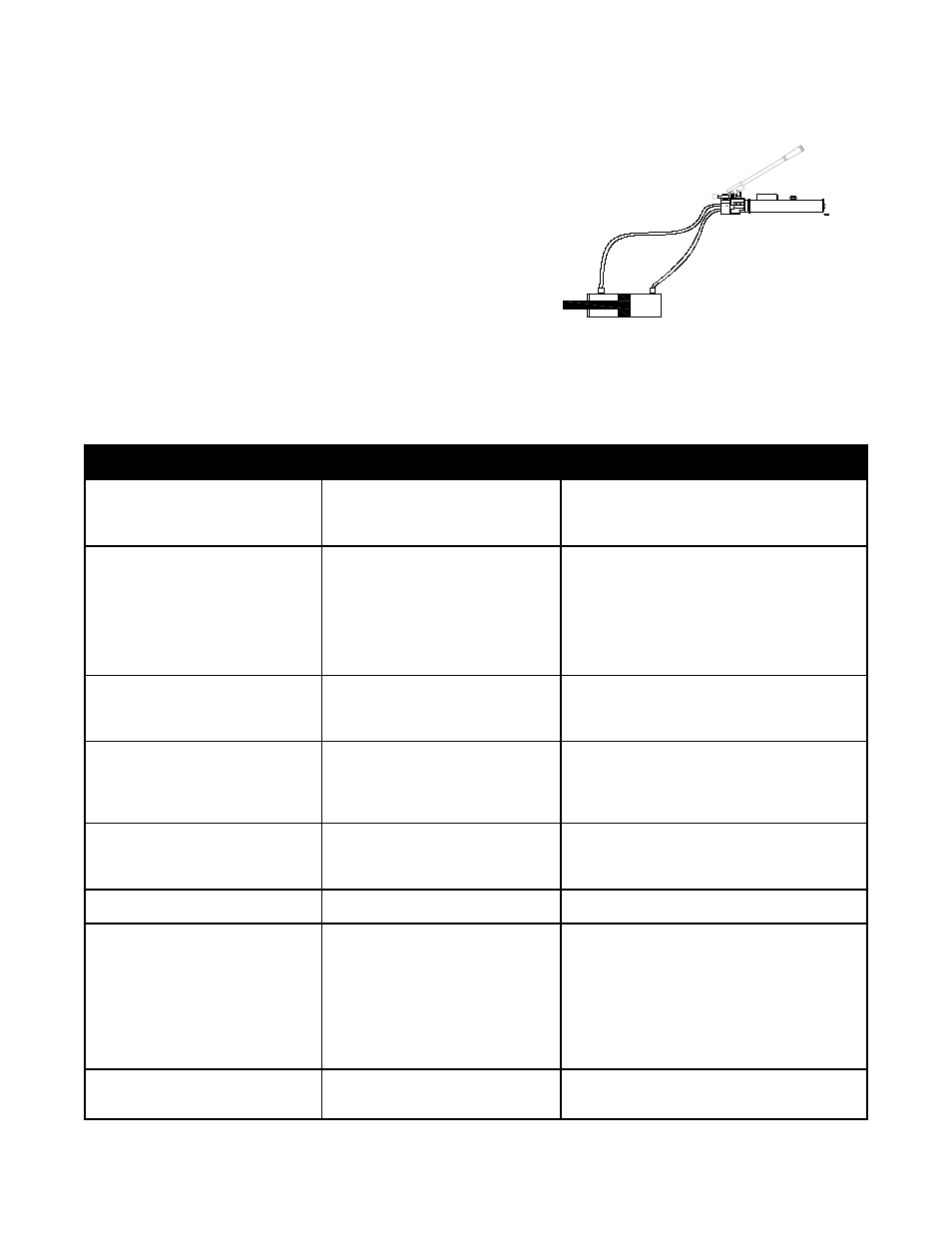

Figure 2 - Illustration to bleed air from system

MAINTENANCE

(cont.)

NOTICE: Do not attempt to grasp with pliers or wrench without

first wrapping the jaws of such tool with rags or similar padding.

How to bleed air from system:

1. Place pump at a higher elevation than the hose and cylinder

as shown in Figure 2.

2. Operate pump to fully extend and retract the cylinder 2 or 3 times.

The objective is to force the air bubbles up hill and back to the

pump reservoir.

3. Follow pump instruction manual to bleed the air from pump

reservoir. On most pumps, air can escape by opening the oil

filler plug/screw.

TROUBLESHOOTING GUIDE

The following information is intended as an aid in determining if problem exists. Cylinders should be repaired only by authorized BVA

Service Center. For repair service, contact service center in your area.

Symptom

Possible Causes

Corrective Action

Erratic action

• Air in system or pump cavitation.

• External leakage in cylinder.

• Cylinder sticking or binding.

• Vent the system (refer to figure 2).

• Contact service center.

• Contact service center.

Cylinder will not extend, or

respond to pressurized fluid

• Overload condition.

• Loose couplers.

• Faulty couplers.

• Improper valve position.

• Oil level in pump is low.

• Pump not operating.

• Air-locked pump.

• Remedy overload condition.

• Tighten couplers.

• Replace both female and male couplers.

• Close release valve or change valve position.

• Fill and bleed the system.

• Check pump’s operating instructions.

• Prime pump per pump operating instructions.

Cylinder extend only partially

• Oil level in pump is low.

• Overload condition.

• Cylinder is sticking or binding.

• Fill and bleed the system.

• Remedy overload condition.

• Contact service center.

Cylinder move slower than normal

• Loose connection or coupler.

• Restricted hydraulic line or fitting.

• Pump not working correctly.

• Cylinder seals leaking.

• Tighten connection or coupler.

• Clean and replace if damaged.

• Check pump’s operating instructions.

• Contact service center.

Cylinder responds to pressurized

fluid, but system does not maintain

pressure

• Overload condition.

• Pump or valve malfunctioning.

• Cylinder seals leaking.

• Remedy overload condition.

• Check pump’s operating instructions.

• Contact

service center.

Oil leaking from cylinder

• Worn or damaged seals.

• Contact service center.

Cylinder will not retract or retracts

slower than normal

• Improper valve position.

• Malfunctioning coupler, damaged

application.

• Pump reservoir overfilled.

• Cylinder damage internally.

• Open release valve or change valve position.

•

Secure load by other means. Depressurize

pump and hoses, remove application and

replace coupler.

•

Secure load by other means. Depressurize

pump and hoses, remove application, then drain

fluid to proper level.

• Contact service center.

Cylinder performs poorly

• Oil level in pump is low.

• Air trapped in system.

• Ensure proper oil level.

• Vent the system (refer to figure 2).