Specifications, Operation, Maintenance – BVA Hydraulics HPD1610 User Manual

Page 4

4

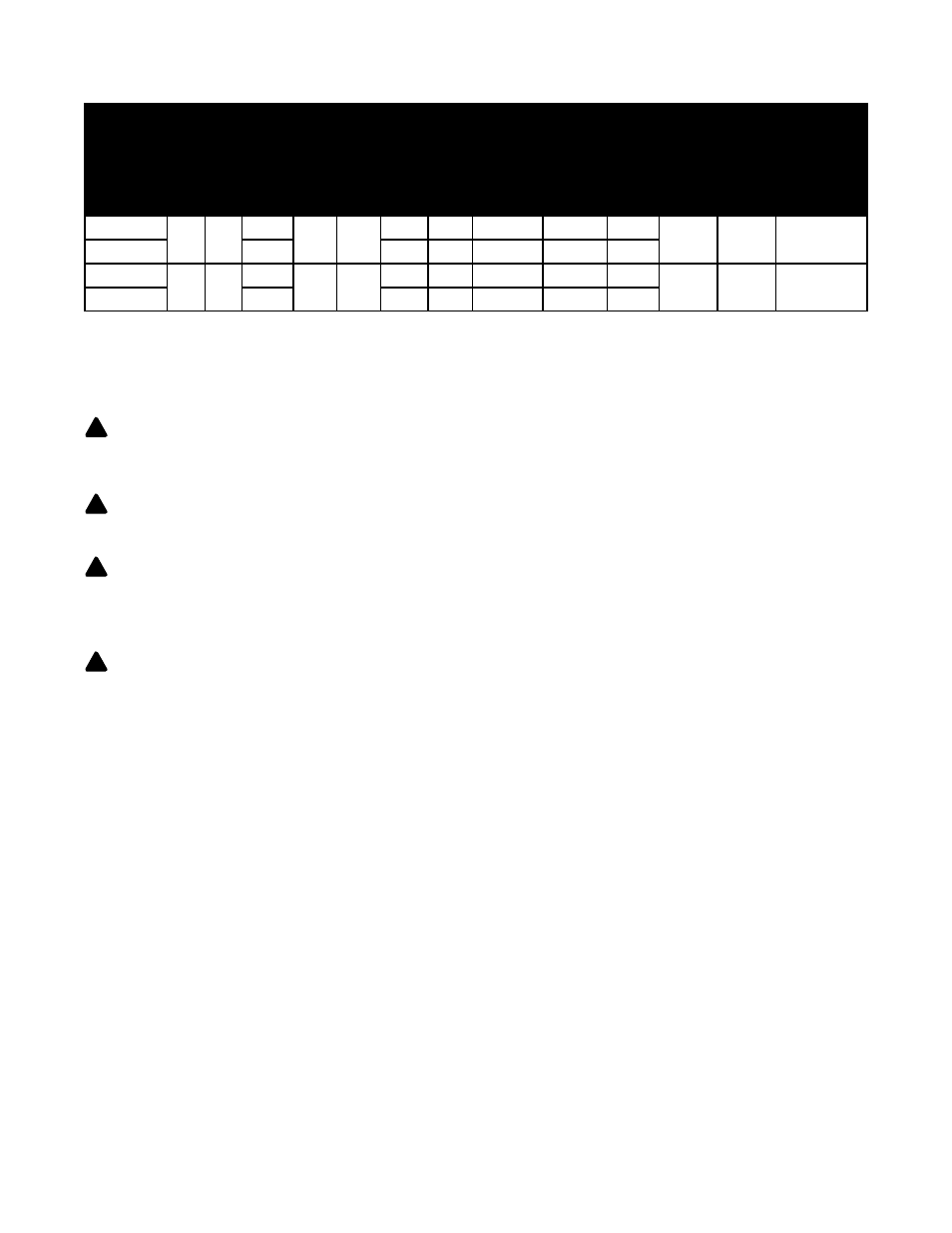

SPECIFICATIONS

Model

Number

Cylinder

Capacity

(tons)

Stroke

(in)

Cylinder

Effective

Area

(in

2

)

Oil Capacity

(in

3

)

Collapsed

Height

(in)

Extended

Height

(in)

Weight

(lbs)

Cylinder

Housing

Dia.

(in)

Collar

Thread

Mounting

Hole Dia.

Push Pull

Push Pull Push Pull

HPD0906

9

5

6.1

1.76

1.00

10.7

6.1

13.78

19.88

14.6

2.52

2”-12

1-11/16”-18

HPD0910

10.11

17.8 10.1

17.80

27.91

18.5

HPD1606

16

8

6.26

3.14

1.56

19.7

9.8

15.31

21.57

22.0

2.99

2 5/8”-16

2-3/16”-16

HPD1610

10.24

32.2 16.0

19.29

29.53

28.2

OPERATION

Operate the hydraulic pump to advance and retract the cylinder.

Do not continue pumping when cylinder is fully extended. Internal

pressure will build up and may damage the seal of the cylinder.

WARNING: NEVER rely on hydraulic pressure alone to

secure a load!

NEVER allow personnel to work or pass under

a load until the load is secured by cribbing, blocking, or other

mechanical means.

WARNING: To help prevent material fatigue if the cylinder

is to be used in a continuous application, the load should not

exceed 85% of the rated capacity.

WARNING: Your cylinder, hose(s), couplings and pump all

must be rated for the same maximum operating pressure,

correctly connected and compatible with the hydraulic fluid

used. An improperly matched system can cause the system

to fail.

WARNING: All personnel must be clear before lowering load.

MAINTENANCE

1. Inspect hoses and connections daily. Replace damaged

components immediately with BVA Hydraulics Replacement

Parts only.

2. Tighten connections as needed. Use pipe thread sealing

compound when servicing connections.

3. Always use clean, approved hydraulic fluid and change as

recommended or sooner if the fluid becomes contaminated

(never exceed 400 hours). Follow pump manufacturers

instructions for changing and adding hydraulic fluid. Use only

good quality hydraulic fluid. We recommend Mobil DTE13M

or equivalent when using with hand pump or air pump; BVA

Hydraulics Oil (F01) or equivalent when using with electric pump.

Never use brake fluid, transmission fluid, turbine oil, motor oil,

alcohol, glycerin etc. Use of other than good quality hydraulic

oil will void warranty and damage the cylinder, pump, hose etc.

4. Use an approved, high-grade pipe thread sealant to seal all

hydraulic connections. Teflon tape can be used if only one layer

of tape is used and it is applied carefully (two threads back) to

prevent the tape from being introduced into hydraulic system. A

piece of tape could travel through the system and obstruct the

flow of fluid and adversely affect function.

Lubrication & Cleaning

Keep cylinder clean at all times.

1. Any exposed threads (male or female) must be cleaned and

lubricated regularly, and protected from damage. Lubricate with

light machine oil.

2. If a cylinder or ram has been exposed to rain, snow, sand,

airborne abrasive, or any corrosive environment, it must be

cleaned, lubricated, and protected immediately after exposure.

Daily clean exposed ram with clean cloth dampened with light

machine oil. Protect exposed ram from the elements at all times.

3. Keep the hydraulic system as free of dirt as possible. When

not in use, couplers must be sealed with dust covers. All hose

connections must be free of dirt and grime. Any equipment

attached to the cylinder must be kept clean.

Storage

Cylinders should be stored vertically with ram plunger fully retracted

in a dry, protected area, not exposed to corrosive vapor, dust or

other harmful elements. When a cylinder has not been used for

a period of 4 months, it should be connected to a pump and fully

extended and then retracted a minimum of 5 times. This cycle will

lubricate the cylinder wall, reducing the possibility of corrosion and

damage thereof.

How to remove faulty coupler:

If cylinder does not retract,

1. Secure load by other means.

2. Depressurize pump and hose.

3. Remove the cylinder from application.

4. Disconnect and replace with new coupler.

!

!

!

!