0 battery symptoms and solutions, continued – Alpha Technologies AlphaCell GelCell Series User Manual

Page 24

745-680-C0-002, Rev.B

24

5.0

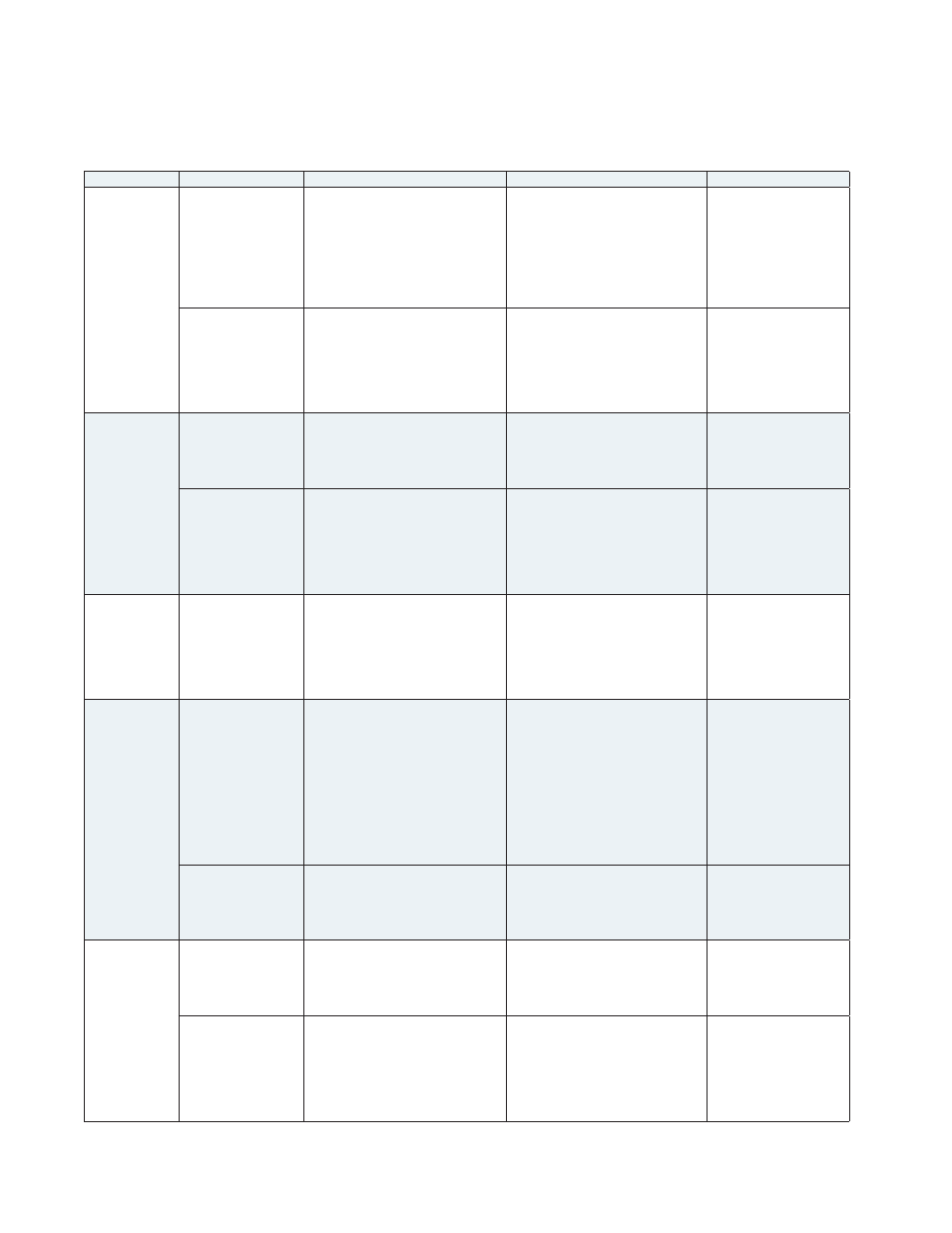

Battery Symptoms and Solutions, continued

Type

Symptom

Possible Causes

Possible Result

Corrective Action

Float Charging

Current

Checks

Float current to

string is zero

A battery or connection in series

string is open. Verify via the float

voltage check or AC ripple voltage

or impedance check of individual

batteries.

Failure to support load. If an

•

internal arc occurs during

discharge, can ignite gasses

internal to cell.

If there is an open/loose

•

connection in external con-

ductive path, can damage

termination under load.

Replace battery with

open cell or repair

open/loose external

connection.

Float current

exceeds 3.0

milliamperes per

ampere hour of

rated capacity at

77°F(25°C) at float

voltage.

Batteries not fully recharged.

•

Batteries above 77°F(25°C)

•

Potentially shorted cells in

•

battery

Depending on degree, bat-

•

tery entering or in thermal

runaway

Not at 100% capacity

•

Conducive to thermal

•

runaway

Thermal runaway results in

•

eventual meltdown of battery

and potential of hydrogen

sulfide emissions and fire.

Determine specific

cause; take corrective

action.

High Rate 10

Second Load

Test

Terminal voltage

marginally below

minimum voltage

specified for 10

second point.

Battery perhaps not fully charged

or is older, in service battery and

has somewhat lower capacity.

Perhaps reduced operating time.

Fully recharge battery.

Terminal voltage

significantly below

minimum voltage

specified for 10

second point.

Battery discharged of

•

battery conductive path,

plate grid, or active material

or electrolyte volume

deterioration.

Shorted.

•

Open cells.

•

Reduced operating time.

•

Conducive to thermal

•

runaway

Will not support load

•

Charge, retest battery

or replace as required.

Battery

Impedance/

Conductance

Test

Impedance /

resistance increase

by 50% from

original values

or conductance

decline to 50% of

the value when new.

Battery discharged or battery

•

conductive path, plate grid or

active material, or electrolyte

volume deterioration.

Shorted cells

•

Open cells

•

Reduced operating time

•

Conducive to thermal

•

runaway

Will not support load

•

Charge and retest

battery or replace as

required.

Connection

Hardware

Resistance

/ Tightness

Check

Connection

resistance increase

20% or more from

original value.

Repetitive cycles results

•

in heating and cooling of

connection, resulting in

relaxation of torque, increase

in connection resistance.

Contamination within

•

the connection results in

corrosion and high terminal

resistance.

Loose connections result

•

in heat damaged or melted

terminals during high rate

discharge.

Excessive voltage drop

•

during high rate discharge

and resulting reduced

operating time

Retorque

•

connection as

required

Correct source

•

of contamination,

clean contact

surface areas,

grease contact

surfaces with anti-

oxidant grease,

reassemble.

Connection

hardware tightness

is less than the

specified "retorque"

value.

Repetitive cycles results in heat-

ing and cooling of connection re-

sulting in relaxation of torque and

increase in connection resistance.

Loose connections result in heat

damaged or melted terminals

during high rate discharge

Retorque the

connection as required

AC Ripple

Voltage

Checks

AC ripple (p-p)

voltage on system

<4% of the value of

the DC float voltage

Poor filtering of charger output.

Excessive AC ripple could cause

the battery to cycle at the ripple

frequency and result in heating

and deterioration of the plate ac-

tive material

Improve the charger

output filtering.

Individual battery in

string exhibits AC

ripple voltage twice

that of other typical

batteries in string.

Battery with high AC ripple

voltage has proportionately

higher impedance. Evaluate

for performance. Subject

battery could have deteriorating

conductive path or dry, shorted or

open cell.

Reduced operating time.

•

Potential conditions could

•

be conducive to thermal

runaway.

Verify battery condition.

Replace as required.

Table 2, Battery Symptoms and Solutions, continued