Preparing for maintenance, Required tools and equipment, Fig. 4, flow chart, monthly status monitoring – Alpha Technologies AlphaCell GelCell Series User Manual

Page 13: 0 periodic maintenance tasks and schedule, 1 monthly remote status monitoring

13

745-680-C0-002, Rev. B

3.0 Periodic Maintenance Tasks and Schedule

The following tasks are to be performed on a monthly and quarterly schedule.

The following maintenance procedure requires a fully functional status monitoring system capable of

remotely measuring and recording the following data on a periodic basis:

Battery Temperature

•

Individual Battery Voltage

•

Total Battery String Voltage

•

Please note: If status monitoring is not available these checks need to be made during the quarterly

onsite visit and any batteries not meeting the minimum requirement must be addressed at such time.

Procedure

1. If any individual battery voltage varies more than 0.5V above or below the average for the

string then a site visit is required.

Example V1 = 13V, V2 = 13V, V3=14V

Average voltage = 13.3V

If V3 greater than average by 0.5V, then a site visit is required

2. If the RTS temperature is greater than 10 degrees C above the current regional ambient

temperature then a site visit is required.

3. Prioritize site visits based on highest RTS temperatures and battery voltages

4. Visit the site within 30 days and remedy the problem by replacing the bad battery or

batteries and reset quarterly maintenance.

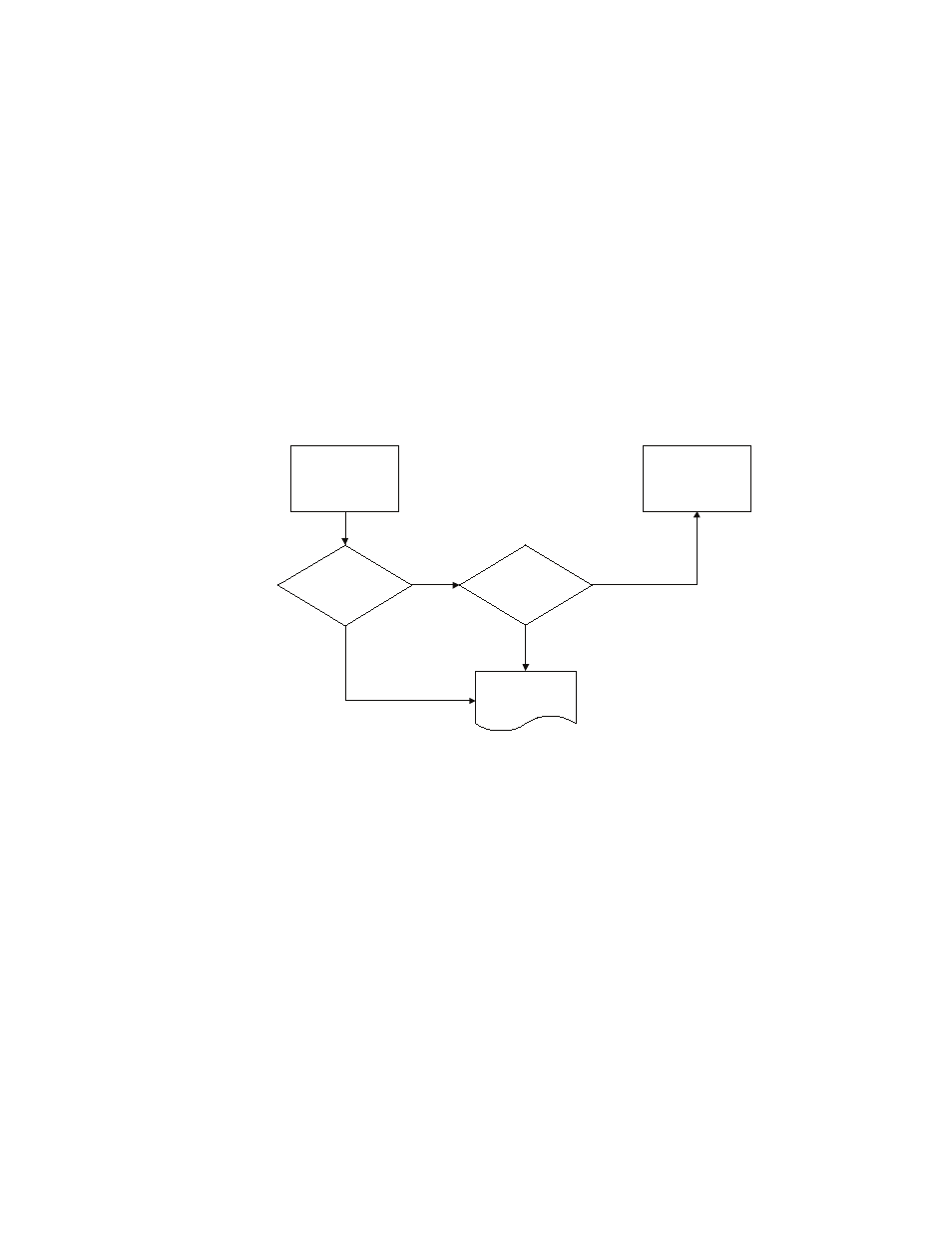

Review Status

Monitoring Data

RTS

Temperature >10C

above Ambient

Battery Voltage

>0.5V Above/Below

String Average

Monitor as per PM

Program

No

No

Yes

Yes

Perform

Quarterly PM

Fig. 4, Flow Chart for Monthly Remote Status Monitoring

3.1 Monthly Remote Status Monitoring