Danger, Warning, Caution – Elmo Rietschle L-BV3 User Manual

Page 17

Commissioning

© Gardner Denver Deutschland GmbH

17 / 32

610.444430.40.000

DANGER

Electrical danger!

The electrical connection may be carried out

by trained and authorized electricians only!

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine

whether

deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

DANGER

Electrical danger!

Depending on the charging state of the

capacitors, a residual voltage may be present

on the terminals in the terminal box.

After opening the terminal box cover, it must

be ensured that the capacitors are completely

deenergized:

Measure the voltage at the corresponding

jumpers (see the circuit diagram in the

terminal box).

Dissipate the residual voltage with suitable

means if necessary.

The capacitors must be completely

deenergized.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the unit or system:

Interrupt supply of operating liquid.

Bleed lines and vacuum pump/compressor

(depressurize).

The further procedure is again dependent

on the unit operating mode:

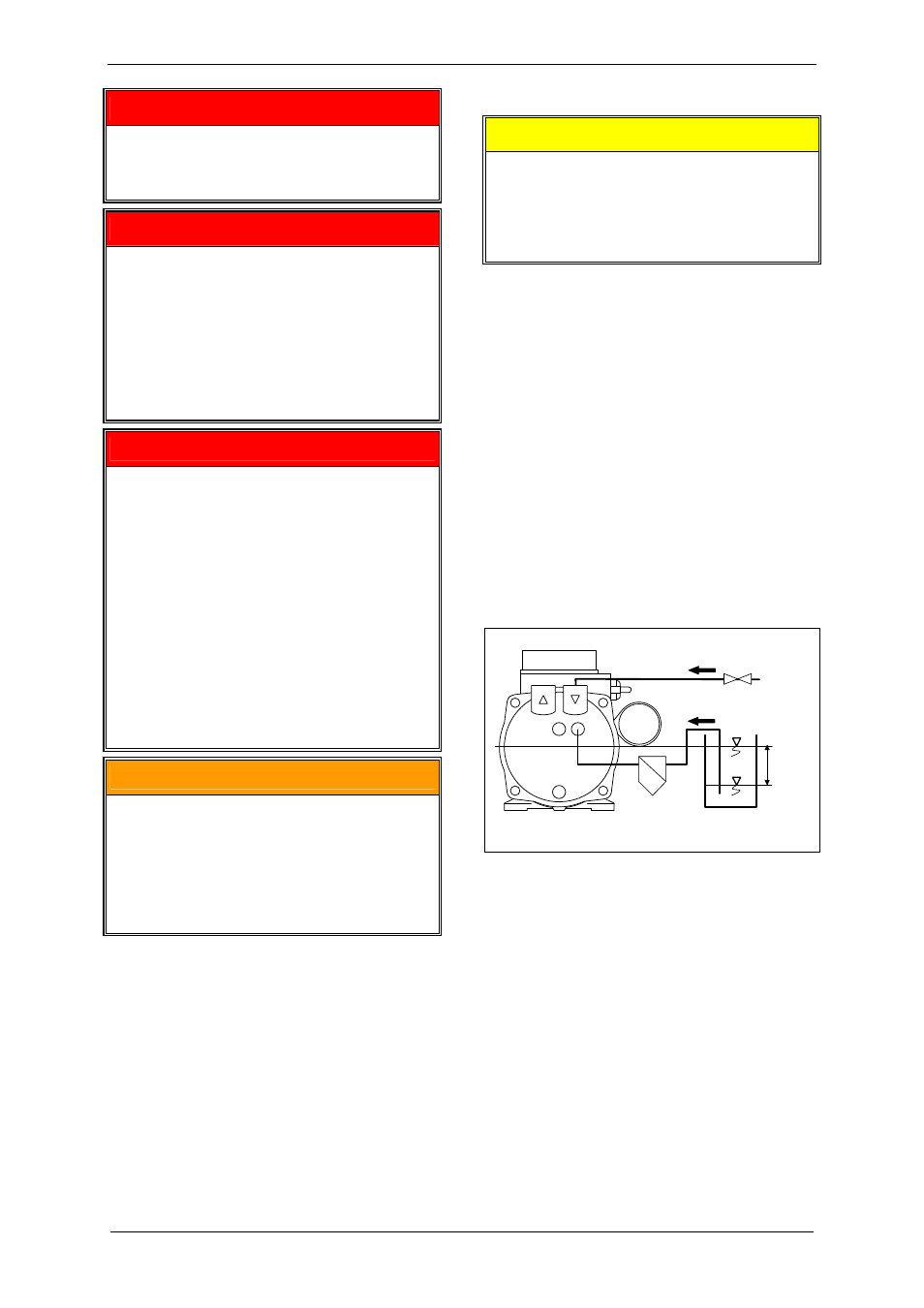

7.2 Self-priming

operation

CAUTION

The liquid level in the feed pipe or in the

reservoir may not exceed the height of the

shaft center of the pump-motor unit!

If this height is exceeded, too much liquid gets

into the pump-motor unit. Damage can occur!

See Fig. 4, Pg. 17.

Here the following must be watched:

The pump-motor unit must be pre-throttled

on the inlet side. This means a vacuum of

at least 80 kPa abs.

[11.6 psia] must be

present in the inlet pipe (Item B) at switch-

on.

During switch-on, the liquid level in the feed

pipe (Item A) and in the reservoir (Item C)

respectively must be at the same level as

the center of the unit shaft (Item 1).

During operation the liquid level in the

reservoir (Item C) may not drop below

approx. 1 m [3.28 ft] below

the center of

the unit shaft (Item 1).

1

2

1 m

3,28 ft

80 kPa abs

11,6 psia

6104443001005

B

A

C

Fig. 4: Self-priming operation

A Feed pipe for operating liquid

B Inlet

pipe

C Reservoir for operating liquid

1 Required liquid level when switching on

2 Min. liquid level during operation

Starting the pump-motor unit:

Switch on the unit.

The operating liquid is sucked in.