Elmo Rietschle V-VC 400/500/700/900/1100/1300 User Manual

Page 13

13

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

|

0DGHLQ*HUPDQ\5RJJHQEDFKVWUDVVH'6FKRSIKHLPZZZJGHOPRULHWVFKOHFRP

(1

99&

PEDUDEV

PñK

N:

YDFXXPSXPS

PLQ

616&

,'

6

Set up and operation

6

8

3

4

5

2

7

9

1

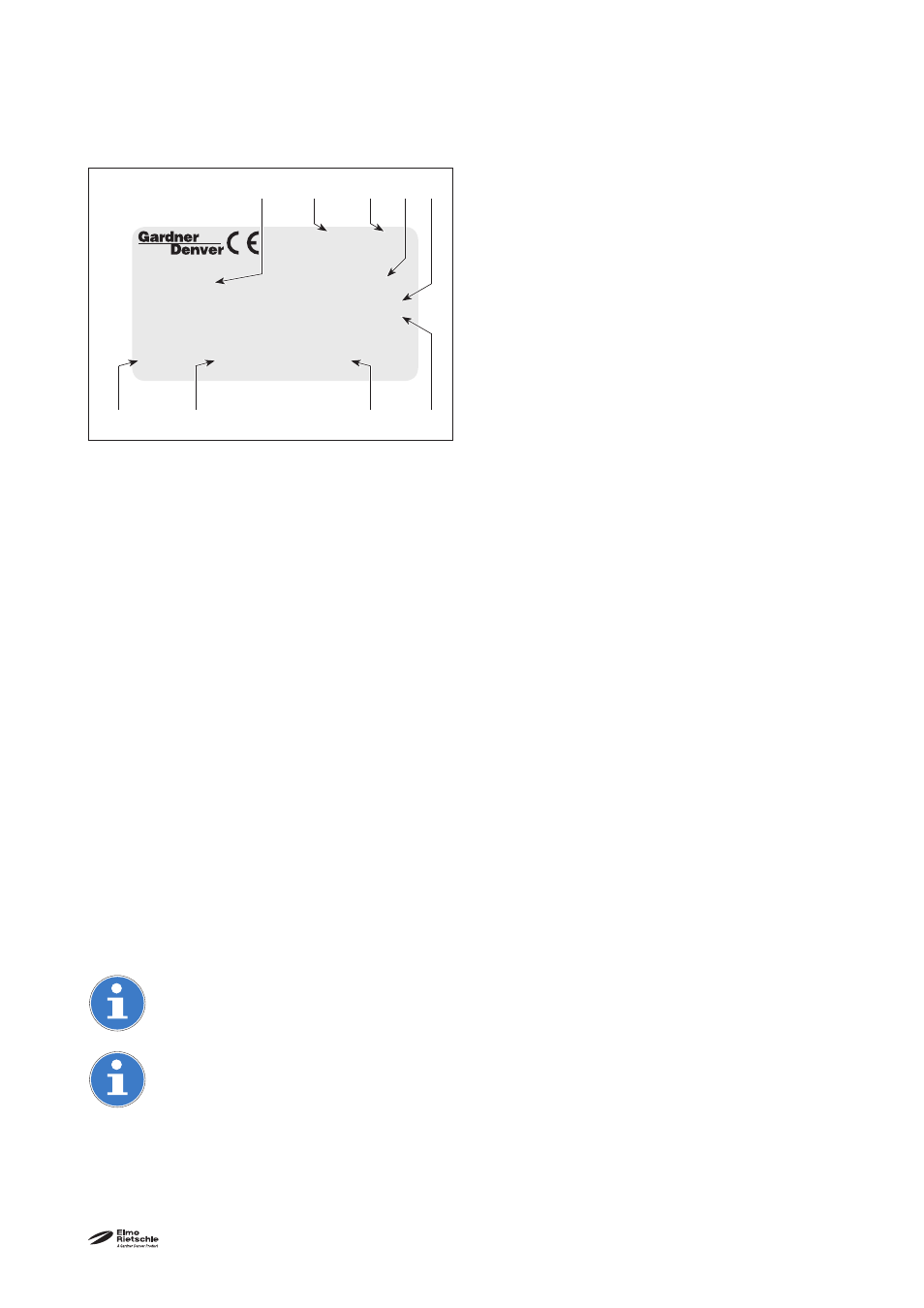

4.1.1 Data plate

Fig. 3 Data plate

4.2 Description

The V-VC 400 - V-VC 1300 have a fi ne micro fi lter or a fi ne fi lter on the suction side and on the outlet side

an oil and oil mist separator to return the oil to the oil circulation system. The vacuum pump is housed in a

sound cover. A fan between the pump housing and the motor provides air cooling. The fan is located in a fan

housing that guards against it being touched. The cooling air also fl ows through an oil cooler. An integral

non-return valve prevents the evacuated system from being ventilated after the pump has stopped. If the

machine has been idle for more than two minutes the connected pipe should be ventilated to atmospheric

pressure.

A gas ballast valve fi tted as standard (Fig. 2/U) prevents condensation of water vapour in the inside of the

pump when low amounts of steam are sucked in when the pump is at operating temperature. A reinforced

gas ballast can be provided for higher amounts of water vapour.

The pumps are driven by standard fl anged three-phase motors using a coupling.

4.3

Areas of application

These oil-fl ooded rotary vane vacuum pumps V-VC 400 to V-VC 1300 are suitable for producing vacuum.

The vacuum capacities at atmosphere are 400, 550, 700, 830, 1100 and 1280 m

3

/hr operating on 50 cycles.

The pumping curves showing capacity against vacuum can be seen in data sheet D 233.

These types are suitable for the evacuation of closed systems or for a continuous vacuum within the follow-

ing intake pressure ranges:

V-VC 400 - V-VC 900: Fine vacuum

➝ 0.5 to 100 mbar (abs.) • Coarse vacuum ➝ 10 to 500 mbar (abs.)

V-VC 1100 / V-VC 1300: Fine vacuum

➝ 1 to 100 mbar (abs.) • Coarse vacuum ➝ 20 to 500 mbar (abs.)

If the unit is operated constantly outside these ranges there is the risk of oil leaking through the outlet open-

ing. When evacuating closed systems the volume to be evacuated must be no more than 2% of the nominal

pumping capacity of the vacuum pump.

If the unit is switched on more frequently (at regular intervals of about 4 times an hour) or at higher

ambient temperatures and intake temperatures, the excess temperature limit of the motor wind-

ing and the bearings may be exceeded.Please contact the manufacturer should the unit be used

under such conditions.

If it is installed in the open air the unit must be protected from environmental infl uences, (e.g. by a

protective roof).

1

Type/ Size (mechanical version)

2 Serial

number

3

Year of construction

4 Item

no.

5 Ultimate

vacuum

(abs.)

6 Suction

capacity

7 Speed

8 Motor

rating

9 Operating

mode