Gorman-Rupp Pumps SFV4A-X 1531245 and up User Manual

Page 41

SFV SERIES X‐PROOF PUMPS

OM-06628

MAINTENANCE AND REPAIR

PAGE E - 18

ment is to remove the screws securing the seal

plate to the motor assembly. Pry the assembled

seal plate and stationary element off the shoulder of

the intermediate. Remove the O‐ring and press the

stationary element and seat out of the seal plate

from the back side.

If no further disassembly is required, proceed to

the appropriate areas in PUMP END REASSEMB

LY.

Seal Removal (With Shaft Sleeve)

Carefully remove the spring retainer and seal

spring. Slide the shaft sleeve and rotating portion

of the seal off the shaft as a unit.

Apply oil to the sleeve and work it up under the rub

ber bellows. Slide the rotating portion of the seal off

the shaft sleeve.

Work a pair of stiff wires with hooked ends between

the rotor shaft and the stationary seat and pull the

stationary seat and O‐ring out of the seal plate.

NOTE

An alternate method of removing the stationary ele

ment is to remove the screws securing the seal

plate to the motor assembly. Pry the assembled

seal plate and stationary element off the shoulder of

the intermediate. Remove the O‐ring and press the

stationary element and seat out of the seal plate

from the back side.

Remove the seal sleeve O‐ring from the rotor shaft.

Proceed to PUMP END REASSEMBLY.

PUMP END REASSEMBLY

NOTE

Reuse of old O‐rings or shaft seal parts will result in

premature leakage or reduced pump performance.

It is strongly recommended that new O‐rings and a

new shaft seal be used during reassembly (see the

parts lists for part numbers).

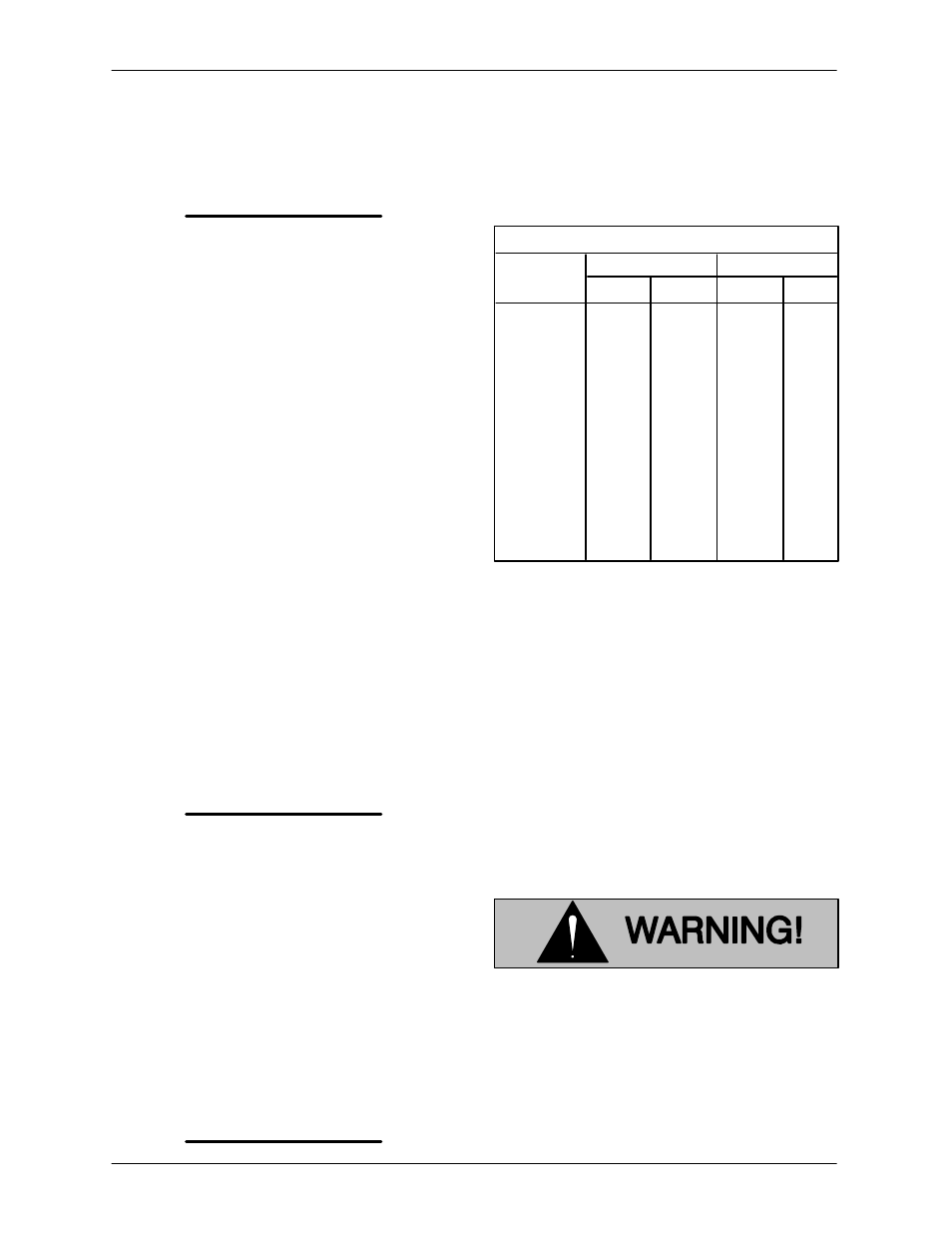

Hardware Torque Values

When reassembling the pump, use the following

table to determine the proper torque values for

hardware.

Table E-1. Hardware Torque Values

TIGHTENING TORQUE

FASTENER

SIZE

DRY

LUBRICATED

FT. LBS.

NM

FT. LBS.

NM

M3

0.8

1,1

0.7

1,0

M4

1.9

2,6

1.2

1,7

M5

3.8

5,1

2.5

3,4

M6

6.5

8,8

52.2

4.3

M8

15.8

21,4

10.7

14,5

M10

32.4

44

22.1

30

M12

54.8

74

36.9

50

M14

87.8

119

58.3

79

M16

135.0

183

89.2

121

M20

273.0

370

180.0

244

M24

220.0

298

145.3

197

M30

421.0

571

276.0

374

Cleaning and Inspection of Pump Parts

With the pump inverted, stuff a clean tissue into the

stationary seal seat bore of the intermediate or

wrap a small rag around the shaft to prevent for

eign material from entering the motor cavity.

Carefully inspect any O‐rings before removal and

cleaning to determine if a proper seal existed prior

to disassembly. If sealing was faulty or question

able, the cause must be determined and corrected

before reassembly. Replace any parts as required.

Thoroughly clean all reuseable parts with a soft

cloth soaked in cleaning solvent. Remove all O‐

rings and clean the sealing surfaces.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Inspect the rotor shaft for damaged threads, scor

ing, or nicks. Remove nicks and burrs with a fine