Gorman-Rupp Pumps SFV4A-X 1531245 and up User Manual

Page 13

OM-06628

SFV SERIES X‐PROOF PUMPS

PAGE B - 5

INSTALLATION

able at the motor must be within the range indi

cated in Table B‐2.

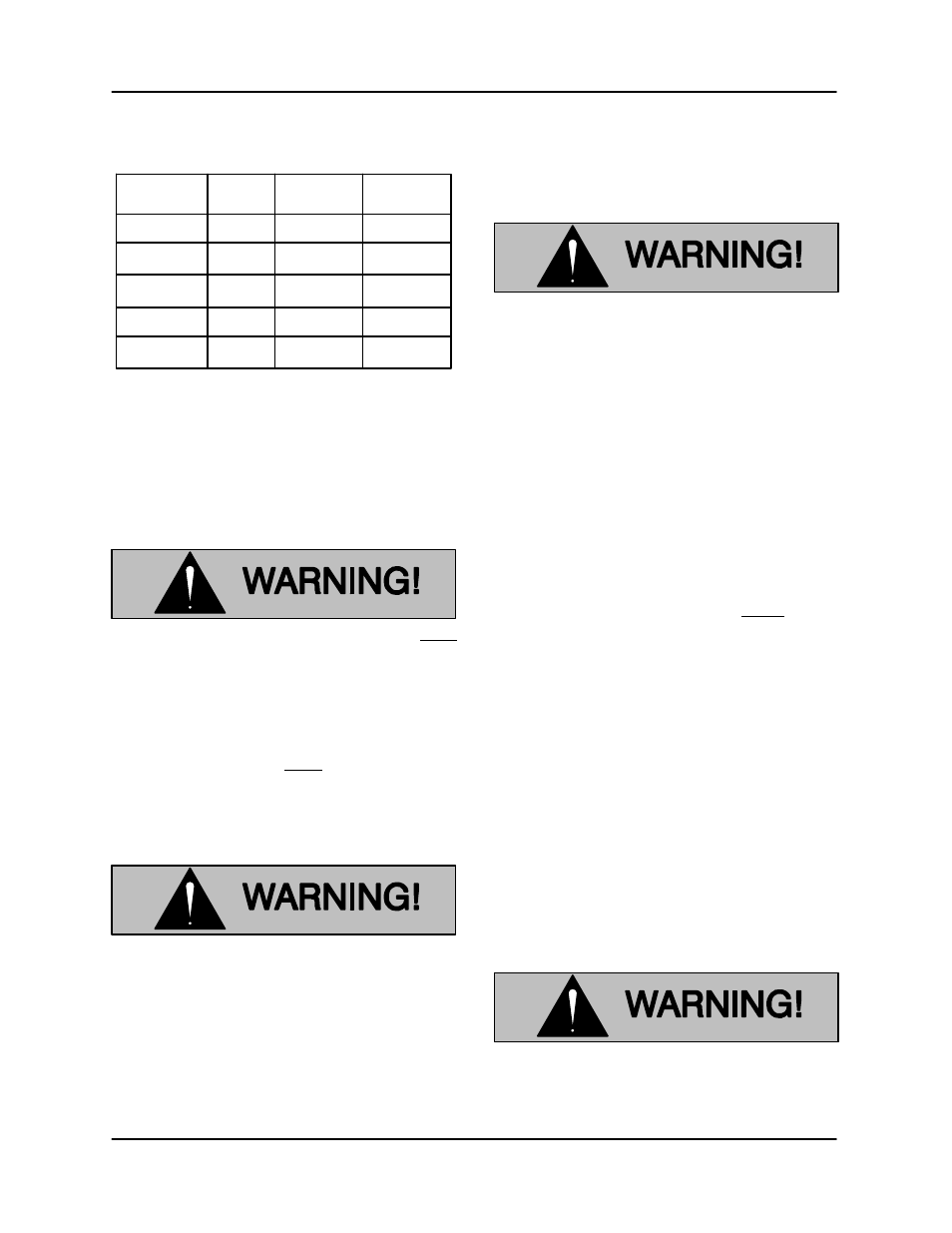

Table B‐2. Pump Voltage Requirements

NOMINAL

VOLTAGE

3

3

230

460

207

414

253

506

PHASE

MINIMUM

VOLTAGE

MAXIMUM

VOLTAGE

3

208

187

229

1

230

207

253

3

575

517

632

Use conduit cable clamps to secure the incoming

field wiring to the control box. Make certain all con

nections are tight. If necessary, support the cable

weight to prevent excessive strain on cable clamps

and cable.

Refer to the wiring diagrams at the end of this sec

tion for field wiring connections.

Dual Voltage

This pump was wired at the factory only

for the voltage shown on the nameplate.

Do not attempt to change the voltage on

a dual‐voltage motor. If desired to have

the voltage changed, return the pump to

the factory or to an authorized Gorman‐

Rupp repair facility only; otherwise, the

pump warranty will be negated, and

damage to the pump, and injury or death

to personnel can result.

Motor Cable Grounding Test

Do not connect the pump control cable

to the control box or incoming voltage

before verifying the pump ground;

otherwise, personnel will be exposed to

serious injury or death.

Connect one lead of a lamp, bell or similar testing

device to the motor cable green/yellow ground

lead (s). Connect the second test lead to an unin

sulated point on the pump body. The test circuit

should close.

If the test circuit does not close, there is a defect in

the cable or motor which must be corrected.

Control Box Connections

The motor powering this pump is ap

proved by either CSA and/or FM for

Class 1, Division 1, Groups C and D en

vironments. Refer to the nameplate on

your pump for agency approval inform

ation. Any liquid level devices used with

the pump must be intrinsically safe for

use in these environments.

Any control box used to operate the

pump must meet all applicable local

and national codes for the application. If

the control box is to be installed in an ex

plosive environment, it must be a Nema

7 rating or better. If a non‐explosion

proof control box is used, it must be lo

cated outside the explosive environ

ment. Improper location of a non‐explo

sion proof control box could result in de

struction of equipment, injury, or death

to personnel.

This pump is shipped completely wired for the volt

age shown on the nameplate and is ready for op

eration through an approved control box.

Ground the control box in accordance with the in

structions accompanying it.

Ground the pump to the control box using the pow

er cable ground(s) and ground check wire (if so

equipped). Secure the ground wire(s) and ground

check wire (if so equipped) to the grounding lug(s)

inside the control box to ensure a thorough ground

for the pump.

Ground the pump using the power cable

ground wire(s) before applying line po

tential. Failure to properly ground the