Gorman-Rupp Pumps SE2C3 115V 1P 1483930 and up User Manual

Page 9

SE SERIES

OM−06492

PAGE B − 2

INSTALLATION

PUMP INSTALLATION

Pump Motor Specifications

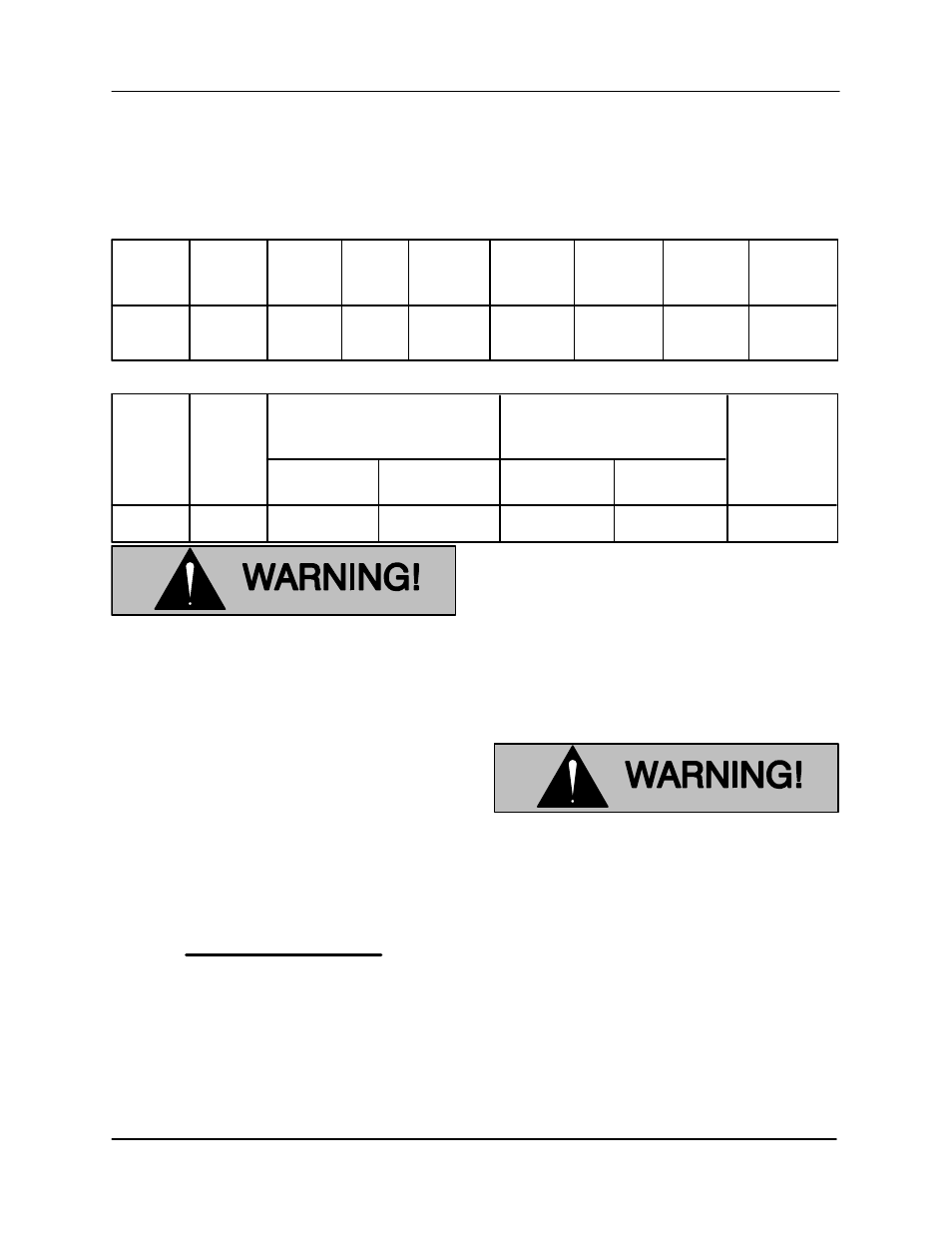

See Tables B-1 and B-2 for pump specifications.

Table B-1. Pump Specifications

Liquid

Level

Control

Locked

Rotor

Amperes

Pump

HP/

KW

Motor

Speed

(RPM)

Full

Load

Amperes

No

Load

Amperes

Discharge

Size

(NPT)

Model

Voltage/

Phase

SE2C3

115/1

NO

6.8

4.3

22.7

1/2 HP

3470

2 INCH

w/BARBED

ADAPTOR

Table B-2. Additional Specifications

Pump

Model

Voltage/

Phase

115/1

SE2C3

Approximate

Weight − Lbs. (kg)

Oil Capacity

Ounces (Liters)

Seal Cavity

Filling

Position

(H)orizontal

Pump

50 Ft. Cable

Seal

Cavity

Motor

Cavity

52 (24)

6 (3)

7 (0,2)

HORIZONTAL

−−−

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical

equipment as outlined in the National

Electric Code. Follow all safety require-

ments. Failure to observe these require-

ments could result in injury or death to

personnel.

NOTE

Refer to the performance curve in Section E, Main-

tenance and Repair when determining the most

efficient piping installation. The recommended

maximum submergence depth is 23 feet. Great-

er depths could result in damage to the pump

Pump Dimensions

For the approximate physical dimensions of your

pump, refer to the pump specification data sheet

or contact your Gorman-Rupp distributor or the

Gorman-Rupp Company.

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer-installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Do not attempt to lift the pump by the

motor power cable or the piping. Attach

proper lifting equipment or a rope to the

lifting device fitted to the pump.

Positioning the Pump

The pump is designed to operate fully or partially

submerged. The rotating parts are oil lubricated,

and the motor is cooled by a constant flow of liquid

or air discharged through internal passages.

The pump will operate if positioned on its side, but

this is not recommended because the motor

torque could cause the pump to roll during opera-

tion.