Gorman-Rupp Pumps SE2C3 115V 1P 1483930 and up User Manual

Page 16

SE SERIES

OM−06492

PAGE C − 3

OPERATION

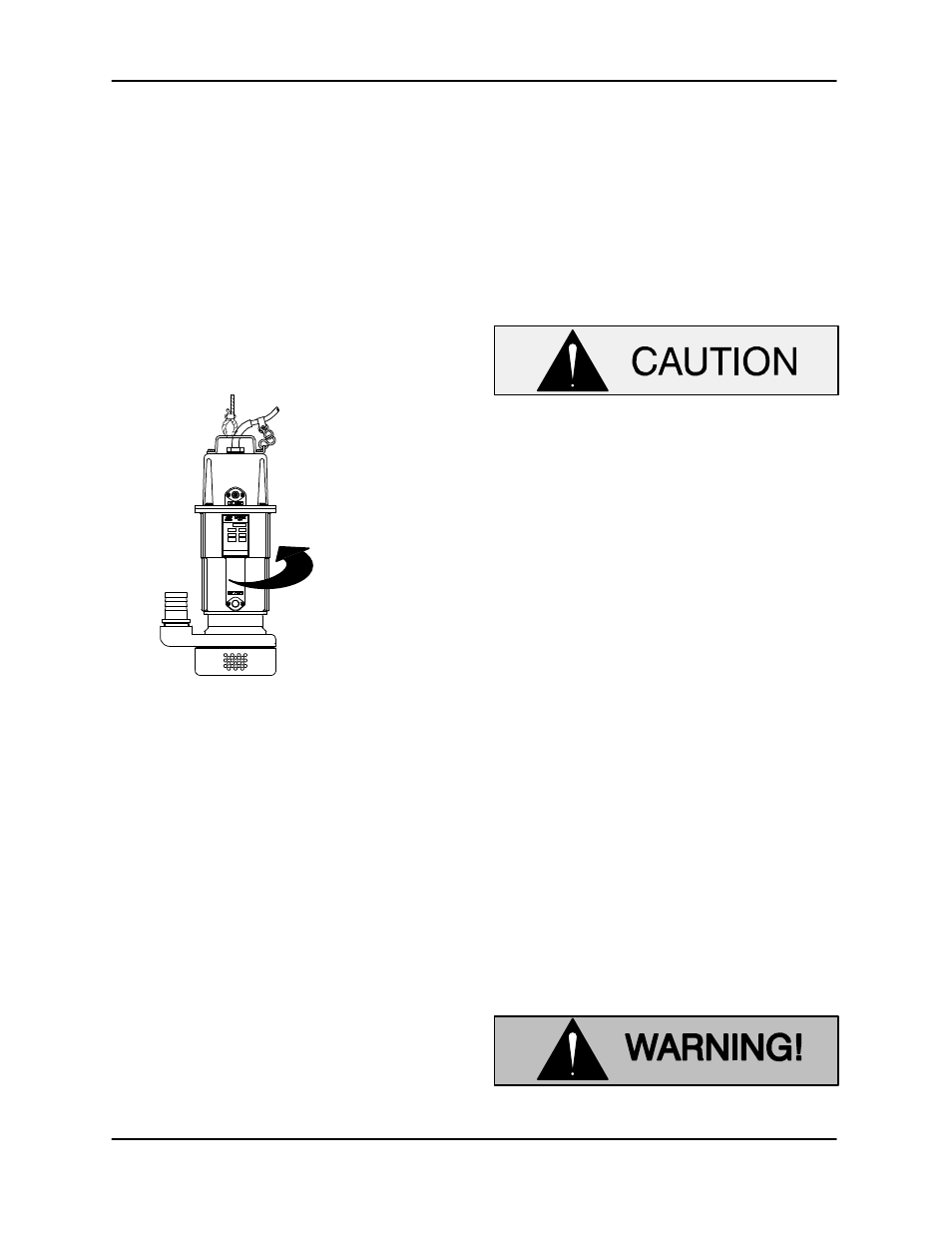

As viewed from the top, the pump should kick in a

counterclockwise direction; this will indicate that

impeller rotation is correct.

If the pump kicks in a clockwise direction, impeller

rotation is incorrect and the pump must be re-

turned to the factory or a Gorman-Rupp authorized

Submersible Repair Center. Since the pump is

powered by a single-phase motor, the direction of

rotation can not be altered by interchanging motor

leads at the control box.

DIRECTION OF

KICKBACK

AT STARTUP

Figure C-1. Checking Pump Rotation

STARTING, STOPPING, AND

OPERATIONAL CHECKS

Starting And Stopping

If an optional control box is used, follow the instruc-

tions accompanying the control box, start the

pump, and run any recommended checks.

After the pump has been installed in a wet well so

that it is fully submerged, start the pump as follows.

If wired into an optional manual switch, trip the

switch within the rainproof enclosure to start or

stop the pump.

If the pump is wired into an optional automatic liq-

uid level control box, set the control box selector

switch to HAND; the pump will continue to run until

the switch returned to OFF, or reset to AUTO.

If desired to operate the pump in the automatic

mode, set the selector switch to AUTO; pump op-

eration will be controlled by the optional float

switch. To terminate automatic mode, move the se-

lector switch to OFF or HAND.

Moving the control box selector switch to

OFF does not terminate incoming power

through the field wiring connected to the

control box.

It is recommended that a check valve or throttling

valve be installed in the discharge line if there is any

possibility of siphoning or back flow when the

pump is shut off.

Operational Checks

Check the pump for proper operation when first

started and periodically thereafter to identify minor

problems.

Check the pump for unusual noises or excessive

vibration while it is operating. If noise or vibration

is excessive, stop the pump and refer to the trou-

bleshooting chart for possible causes.

Check the pump strainer screen for clogging

caused by stones, sticks, or other debris. Clean

the strainer screen when required. In some cases,

stopping the pump momentarily may back flush

the strainer screen, purging most of the debris

from it. If this fails to clean the screen, remove the

pump from the sump and remove the debris manu-

ally. See PUMP DISASSEMBLY in the Mainte-

nance And Repair manual.

Never introduce air or steam pressure