Gorman-Rupp Pumps SE2C3 115V 1P 1483930 and up User Manual

Page 36

OM−06492

SE SERIES

MAINTENANCE & REPAIR

PAGE E − 14

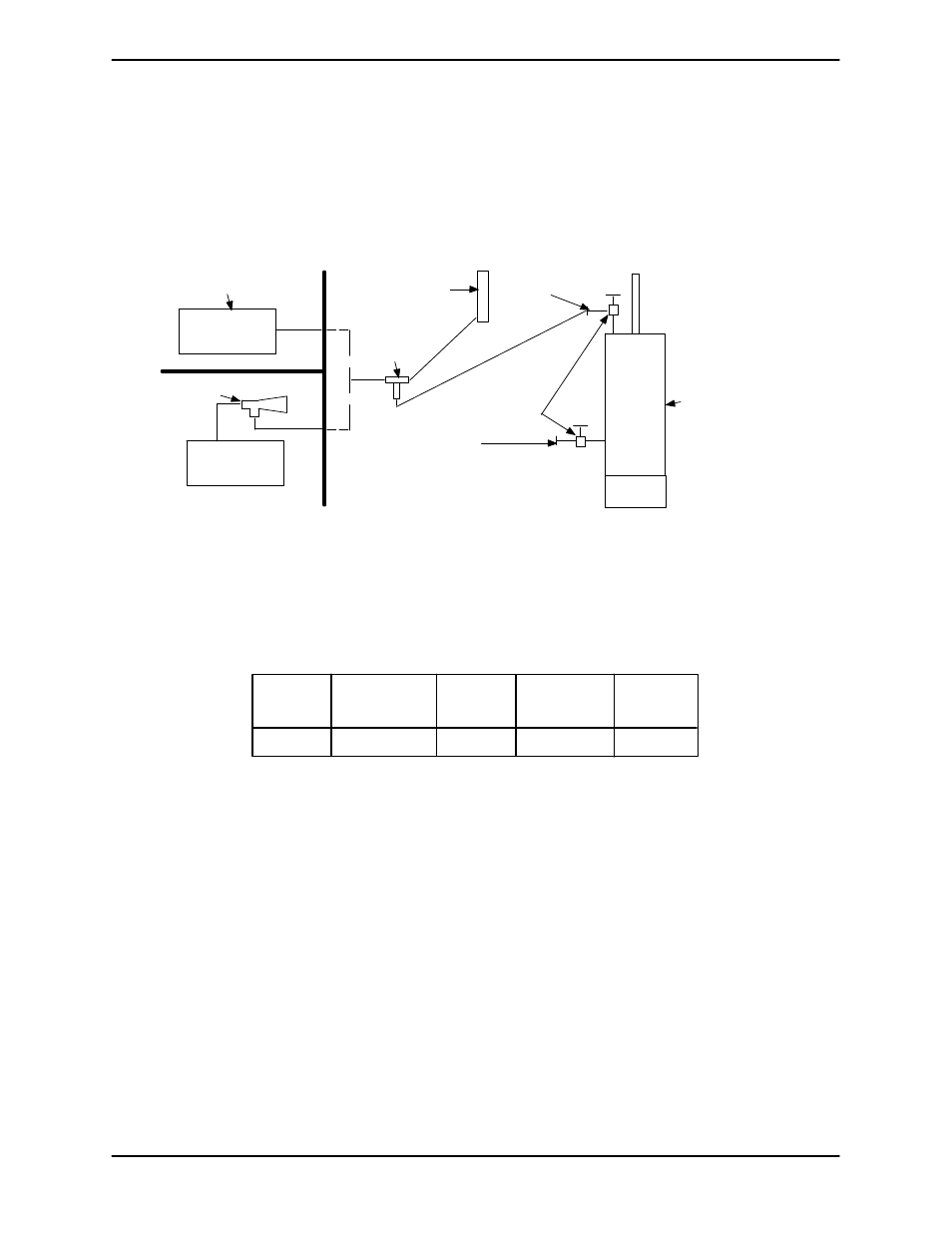

tem may be used. If the compressor/venturi cannot

draw the vacuum level shown in Table E-1, draw

the motor cavity vacuum down as far as the system

will allow, then pressurize the seal cavity so the dif-

ferential between the two cavities is the same as

the differential between the readings shown in the

table.

If a compressor/venturi system is used, install full-

closing ball-type shutoff valves with quick-discon-

nect fittings in the pipe plug holes in both the motor

and seal cavities. This will allow the pressure (or

vacuum) to be maintained while using the com-

pressor to perform the second portion of the test.

Figure E-3 shows a simple schematic for setting up

either a vacuum pump or a venturi/compressor

test system.

ООО

ООО

ООО

Tee

Manometer

Vacuum Pump

Submersible

Pump

Full-Closing

Ball-Type

Shutoff Valve

Quick Disconnect

Fitting

Quick Disconnect

Fitting

Air Compressor

Venturi

Vacuum Test

Motor Cavity

Use Compressor

to Pressure Test

Seal Cavity

Figure E-3. Vacuum/Pressure Test System

Table E-1 shows the motor cavity vacuum and seal

cavity pressure readings for the test, and the dura-

tion to maintain each reading. Any change in the

readings during the test indicates a leak which

must be identified and corrected before putting the

pump back into service.

Table E-1. Vacuum/Pressure Test Data

Seal Cavity

Pressure

(PSI)

Pump

Model

Motor Cavity

Vacuum

(In. Hg.)

Duration

(Minutes)

Duration

(Minutes)

S2C3

30

1

15

1