Gorman-Rupp Pumps 62 1/2D1-CH23 S/G 1211015 and up User Manual

Page 27

60 SERIES

OM--05171

MAINTENANCE & REPAIR

PAGE E -- 10

Impeller Installation

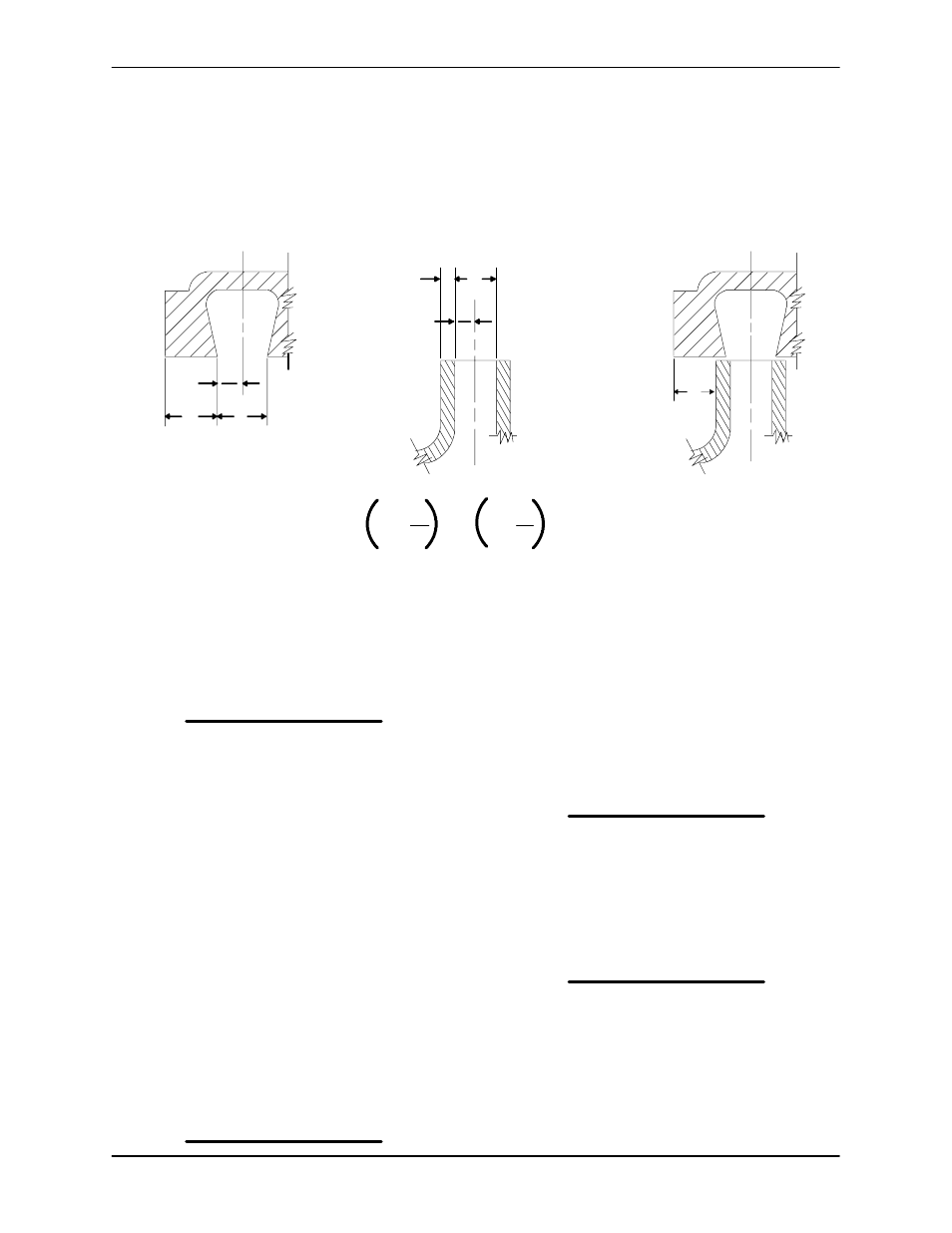

(Figures 2 and 5)

Inspect the impeller (2), and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller must

be centered within the volute scroll. To verify impel-

ler positioning, measure the pump casing and im-

peller as shown in Figure 5. Use these measure-

ments to calculate the required impeller location

(dimension E). Add or remove impeller adjusting

shims (55) to obtain dimension E.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+ B

2

C+ D

2

E

=

---

Figure 5. Centering Impeller Within Pump Casing

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping or

binding before further reassembly.

Pump Reassembly

(Figure 2)

If the wear ring (12) was removed, apply ‘Loctite

No. 242 Threadlocker’ or equivalent compound)

between the casing and the wear ring. Position the

replacement ring in the casing bore so that cham-

fer on the I.D. faces toward the impeller. Press the

ring into the bore until fully seated against the cas-

ing shoulder.

NOTE

The wear ring must be fully seated in the casing

bore, otherwise binding and/or excessive wear

could result.

Install the pump casing gasket (10). Carefully

guide the wear ring into the eye of the impeller, and

secure the casing to the intermediate with the nuts

(5).

NOTE

After the pump casing has been install check the

impeller for free rotation. Correct any scraping or

binding before further reassembly.

Exhaust Primer Reassembly

(Figure 3)

NOTE

Before assembly, apply pipe sealant on all

threaded joints.

To install the exhaust primer body (1) screw the

body into the muffler (4). To assemble the exhaust

primer, install the handle (11) and install the various

primer components.

Screw the hose adaptor (8) into the swivel fitting

(7). Install the gas cock valve (10) and pipe nipple

(6).