Operation – Gorman-Rupp Pumps 62 1/2D1-CH23 S/G 1211015 and up User Manual

Page 12

60 SERIES

OM--05171

OPERATION

PAGE C -- 1

OPERATION --- SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

This pump is designed to handle clear

water in high pressure distribution. Do

not attempt to pump volatile, corrosive,

or flammable liquids which may dam-

age the pump or endanger personnel as

a result of pump failure.

Never tamper with the governor to gain

more power. The governor establishes

safe operating limits that should not be

exceeded.

PRIMING

Install the pump and piping as described in

IN-

STALLATION. Make sure that the piping connec-

tions are tight, and that the pump is securely

mounted. Check that the pump is properly lubri-

cated (see

LUBRICATION in MAINTENANCE

AND REPAIR).

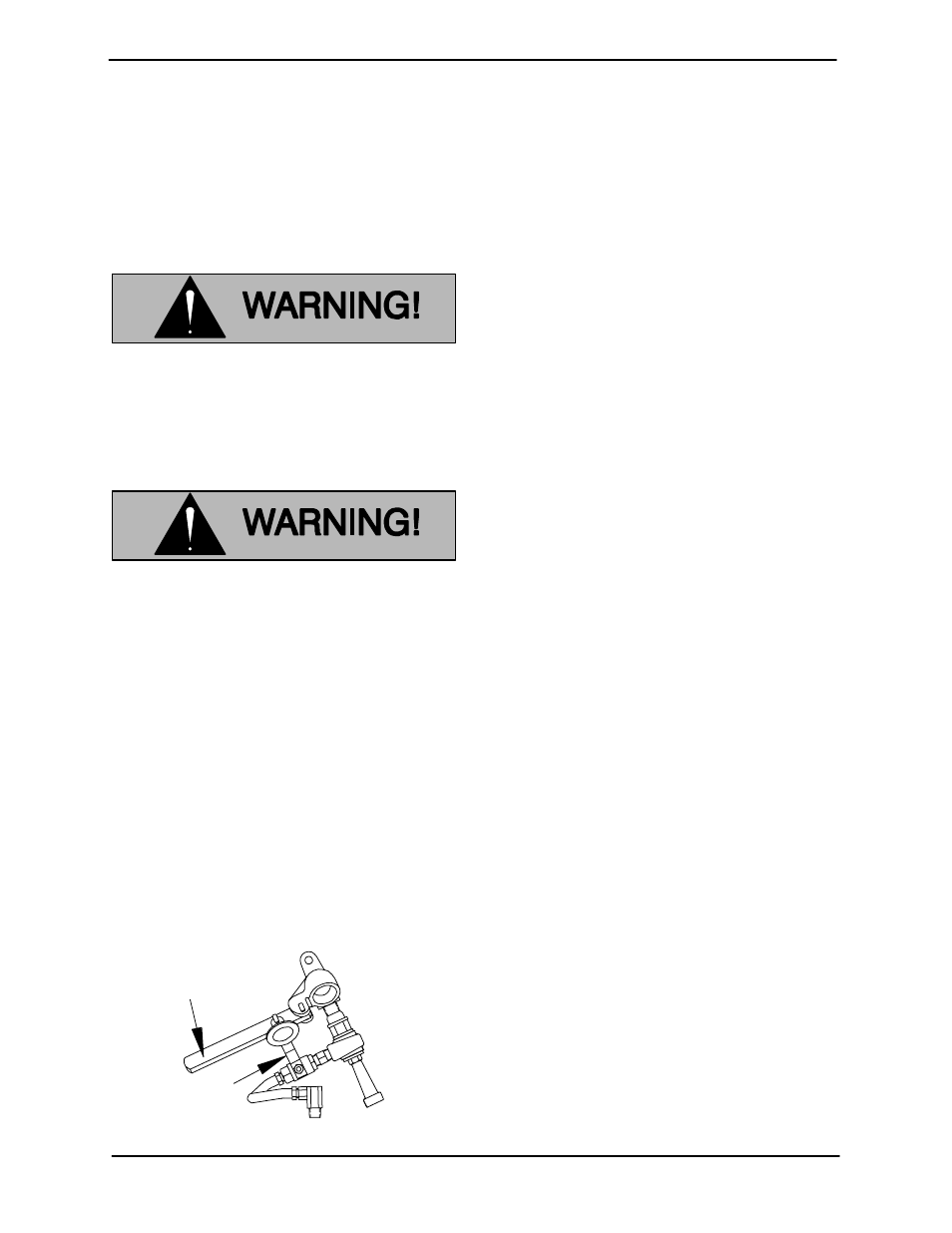

Exhaust Primer

Since this pump is not self-priming, it is equipped

with an exhaust primer assembly (Figure 1).

HANDLE

GAS COCK

Figure 1. Exhaust Primer Assembly

The exhaust primer utilizes engine exhaust gases,

directed through a venturi, to create a vacuum and

draw air out of the suction line and pump casing.

The exhaust primer is capable of priming a pump

with a maximum priming lift of 15 feet (4,6 meters)

within 90 seconds; less time will be required for

priming at a lesser lift. If the pump does not prime in

a reasonable length of time, check the suction line

for leaks.

To prime the pump, close the throttling valve in the

discharge line.

Close the exhaust primer handle (see Figure 1),

and open the cock in the priming line. Consult the

starting instructions in this manual as well as the

engine operating manual, and start the engine.

Operate the engine at maximum governed speed

and allow the pump to prime until liquid flows con-

tinuously from the exhaust primer nozzle. When

the pump is fully primed, open the exhaust primer

handle, and close the cock in the priming line.

Once fully primed, reduce the engine speed and

partially open the discharge throttling valve. The

discharge line should be filled slowly to prevent

damage to the piping, gaskets, and other devices,

resulting from the initial shock of liquid filling the

lines. When the discharge line is completely filled,

adjust the discharge throttling valve to the desired

flow rate.

STARTING

Consult the operations manual furnished with the

engine.

Attach the fuel line to the quick-connect fitting lo-

cated on the engine. Position the portable fuel tank

at the same level as the pump, or slightly higher.

Squeeze the priming bulb until the fuel can be seen

in the transparent fuel line at the carburetor inlet.

The transparent fuel line need not be completely

full. Fuel will be pulled into the carburetor while

cranking the engine with the choke on.

Set the ignition toggle switch to the

ON position.