Gorman-Rupp Pumps 62 1/2D1-CH23 S/G 1211015 and up User Manual

Page 26

OM--05171

60 SERIES

MAINTENANCE & REPAIR

PAGE E -- 9

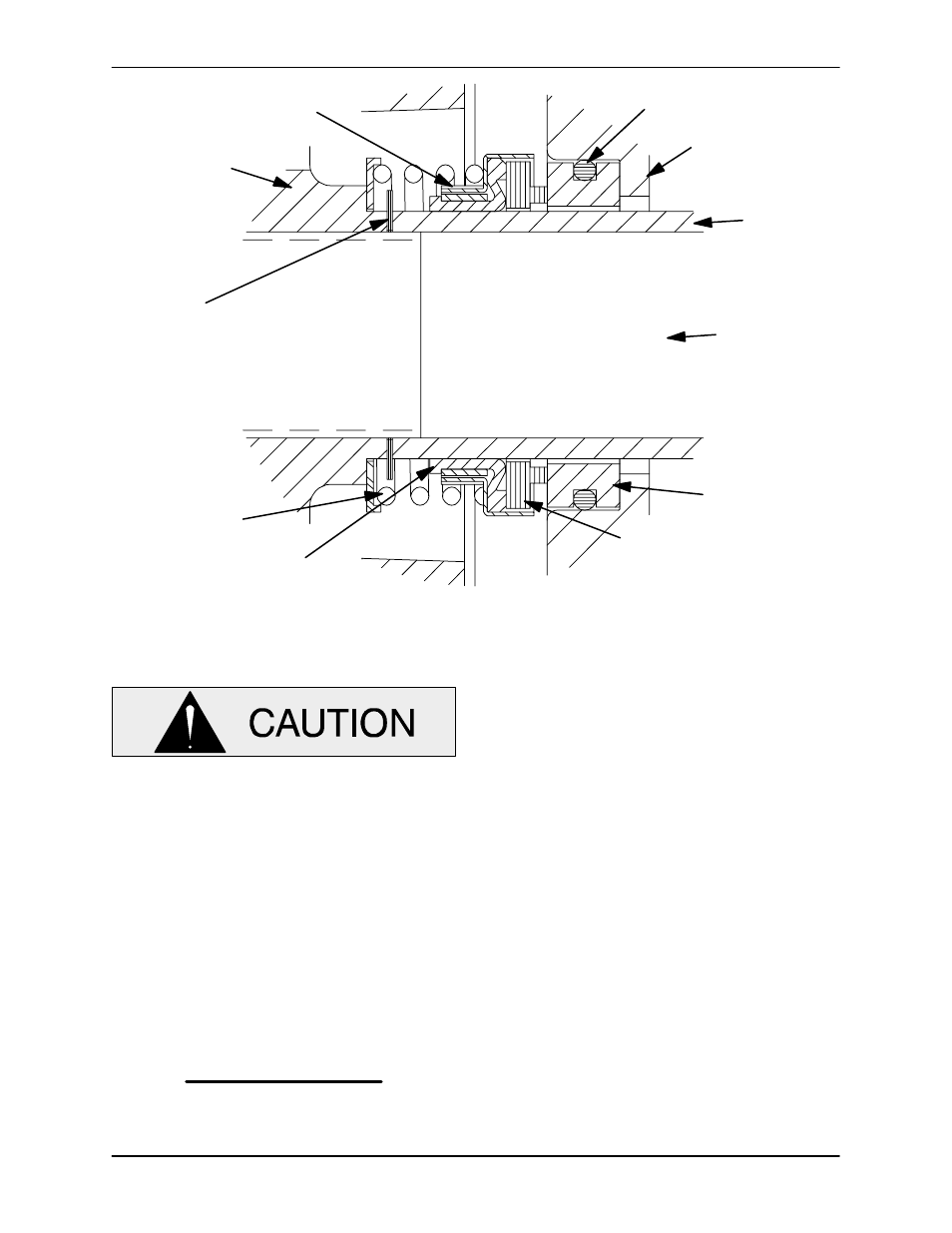

IMPELLER

IMPELLER

SHAFT

O-RING

RETAINER

BELLOWS

SPRING

ROTATING

ELEMENT

STATIONARY

ELEMENT

INTERMEDIATE

IMPELLER

SHIM SET

SHAFT

SLEEVE

Figure 4. 25271--903 Seal Assembly

This seal is not designed for operation at

temperatures above 160_F (71_C). Do not

use at higher operating temperatures.

If the balance ring (9) was removed, the replace-

ment ring should be pressed into the intermediate

before installing the seal. Position the ring in the in-

termediate bore with the chamfered end toward to-

ward the bore shoulder and press it into the bore

until fully seated.

NOTE

The balance ring must be fully seated in the inter-

mediate bore, otherwise binding and/or excessive

wear could result.

If the intermediate was removed, lay it on a flat sur-

face with the impeller side facing up.

Lubricate the stationary seat O-ring with light oil

and install it in the stationary seat. Use thumb pres-

sure to press this subassembly into the intermedi-

ate bore until fully seated. Be careful not to damage

the seal face. After installation, wipe the seal face in

a concentric pattern with a clean, lint-free cloth to

remove any fingerprints.

Secure the intermediate to the engine with the

hardware (26 and 27).

Be careful not to damage

the stationary seat on the shaft threads.

Slide the rotating portion of the seal (consisting of

the retainer, bellows and rotating element) onto the

sleeve (8) until the rotating face is

just flush with

the chamfered end of the sleeve. Slide the sleeve

onto the shaft until the seal faces contact. Continue

to push the sleeve through the seal until it seats

against the shaft shoulder.

Install the seal spring. Make sure that all compo-

nents of the seal are seated squarely.