Gorman-Rupp Pumps 04B3-F4L 1242057 thru 1316965 User Manual

Page 9

OM--01216

0 SERIES

PAGE B -- 2

INSTALLATION

AND REPAIR section of this manual and per-

form duties as instructed.

e. If the pump and engine have been stored for

more than 12 months, some of the compo-

nents or lubricants may have exceeded their

maximum shelf life. These

must be inspected

or replaced to ensure maximum pump serv-

ice.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to deter-

mine the repair or updating policy.

Do not put the

pump into service until appropriate action has

been taken.

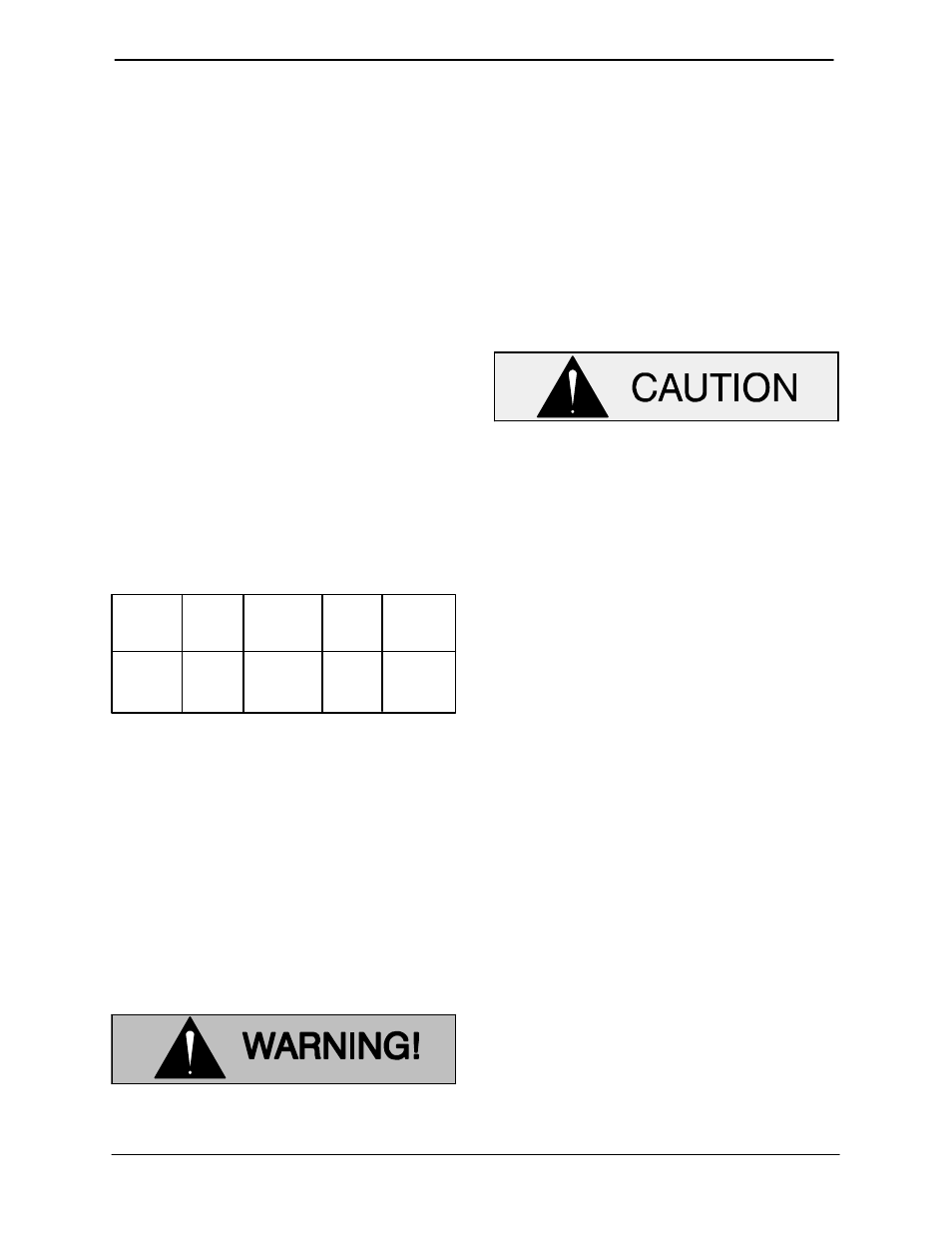

Battery Specifications And Installation

Unless otherwise specified on the pump order, the

engine battery was

not included with the unit. Re-

fer to the following specifications when selecting a

battery.

Table 1. Battery Specifications

Crank

@ 0

_

F

Reserve

Capacity

(Minutes)

@ 80

_

F

Overall

Dims.

(Inches)

960---975

365

20.5L

Cold

Amps

Approx.

Amp/

Hr.

Rating

175

8.75W

9.75H

x

x

Voltage

12 Volts

Refer to the information accompanying the battery

and/or electrolyte solution for activation and charg-

ing instructions.

Before installing the battery, clean the positive and

negative cable connectors, and the battery termi-

nals. Secure the battery by tightening the

holddown brackets. The terminals and clamps

may be coated with petroleum jelly to retard corro-

sion. Connect and tighten the positive cable first,

then the negative cable.

POSITIONING PUMP

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or dam-

age to equipment. Suction and dis-

charge hoses and piping must be re-

moved from the pump before lifting.

Lifting

Use lifting equipment with a capacity of at least

7,650 pounds (3540 kg.). The pump weighs ap-

proximately

1,560pounds (708 kg.), not including

the weight of any customer installed options. Cus-

tomer installed equipment such as suction and dis-

charge piping

must be removed before attempting

to lift.

The pump assembly can be seriously

damaged if the cables or chains used to lift

and move the unit are improperly wrapped

around the pump.

Alignment

The alignment of the pump end and engine are crit-

ical for trouble-free performance. During repair of

the pump end, refer to

Securing Intermediate and

Drive Assembly to Engine in MAINTENANCE

AND REPAIR, Section E for Details.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount-

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra-

tion.

If the pump has been mounted on a moveable

base, make certain the base is stationary by setting

the brake and blocking the wheels before attempt-

ing to operate the pump.

To ensure sufficient lubrication and fuel supply to

the engine,

do not position the pump and engine

more than 15_ off horizontal for continuous opera-

tion. The pump and engine may be positioned up

to 30_ off horizontal for

intermittent operation

only; however, the engine manufacturer should be

consulted for continuous operation at angles

greater than 15_.