Gorman-Rupp Pumps 06C1-GHH 1071445 and up User Manual

Page 38

OM-03179

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 13

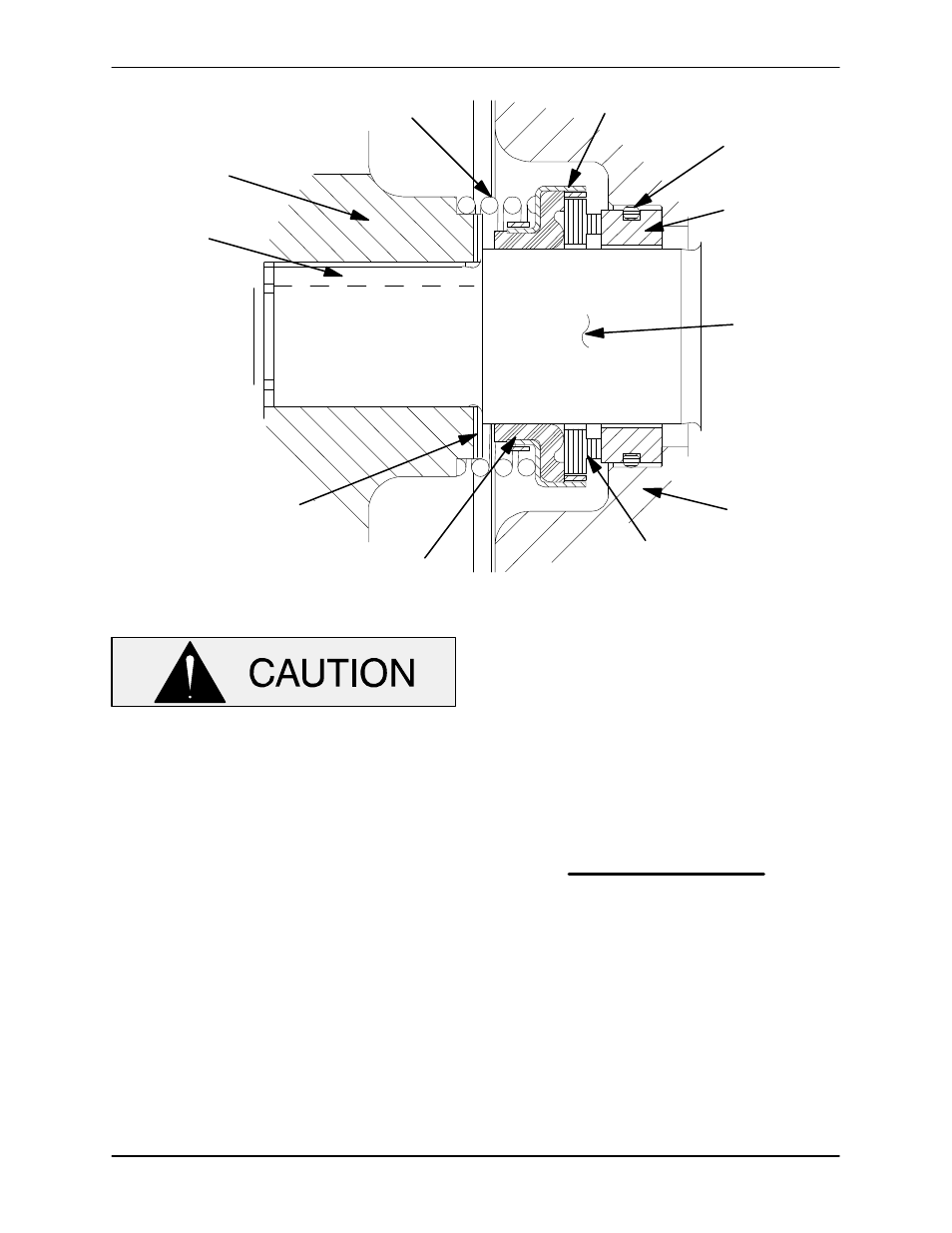

IMPELLER

SHAFT

STATIONARY

SEAT

O‐RING

ROTATING

ELEMENT

BELLOWS

RETAINER

SPRING

IMPELLER

ADJUSTING

SHIMS

IMPELLER

IMPELLER

KEY

PUMP

CASING

Figure 4. 25271-903 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Inspect the impeller shaft for distortion, nicks,

scratches, or damage to the shaft keyway. Dress

small nicks and burrs with a fine file or emery cloth.

If the shaft is defective, refer to GEARBOX DISAS

SEMBLY and replace the shaft.

Lubricate the stationary element O‐ring with a light

coat of oil. Place a clean, lint‐free tissue over the

seal face, and use thumb pressure to press the ele

ment and O‐ring into the pump casing until fully

seated. Be careful not to damage the seal face. Af

ter installation wipe the seal face in a concentric

pattern with a clean, lint‐free cloth to remove any

fingerprints.

NOTE

If the pump casing was removed, install the casing

O‐ring and gasket (18 and 19) on the pump casing

studs. Carefully slide the casing over the shaft, and

secure it to the gearbox with the nuts (15).

Install a tapered sleeve (see Figure 5) over the shaft

keyway to ease installation of the rotating portion of

the seal. This tool can be made from steel tubing or

pipe.