Gorman-Rupp Pumps 06C1-GHH 1071445 and up User Manual

Page 12

OM-03179

0 SERIES

PAGE B - 5

INSTALLATION

sion jack with custom brackets should be

used to lift and position the pump and

gearbox.

Mounting Location

The following factors must be considered when se

lecting a mounting location for the pump.

a. Mounting brackets

b. Universal joint angles

c. Shift linkage

d. Piping

e. Ground clearance

f. Accessibility of pump and gearbox for service.

.

Any damage to the pump or gearbox resulting from

improper mounting and installation is not covered

by the Gorman‐Rupp Warranty.

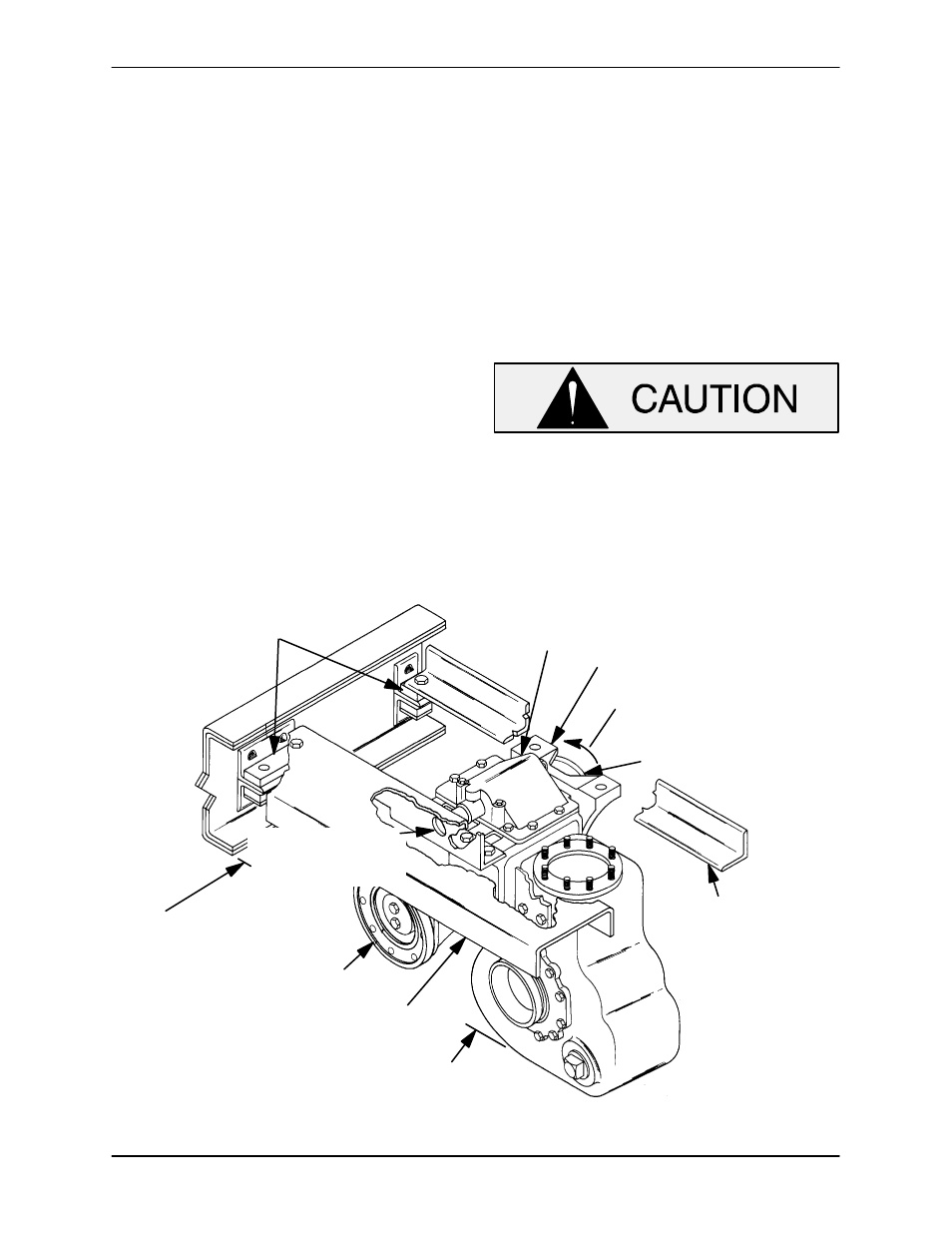

Mounting Brackets

The customer must furnish two cross members

which fit between the vehicle chassis side rails (see

Figure 2). They must be heavy enough to support

the weight of the pump assembly and provide easy

access for pump maintenance.

Secure the rear cross member rigidly to the pump

and gearbox using a fabricated mounting bracket

(customer‐furnished). The mounting bracket must

fasten to the threaded holes located in the pump

casing above the pump suction, and in the top of

the gearbox housing. The bracket and cross mem

ber must not obstruct pump operation or impede

removal of the pump casing during maintenance.

The rear cross member or mounting

bracket must not interfere with movement

of the air shift indicator shaft (located on

top of the gearbox). If necessary, drill a

1.25 inch (31,8 mm) diameter hole through

the cross member or bracket to provide

clearance.

SHIFT COVER

TRUNNION BRACKET

DRIVE INPUT FROM

TRANSMISSION

FRONT CROSS MEMBER

(SUPPLIED BY CUSTOMER)

REAR CROSS MEMBER FURNISHED 40 IN. [1016 MM]

LONG - CUSTOMER TO CUT TO DESIRED LENGTH FOR

INSTALLATION

OUTPUT TO REAR AXLE

1.25 IN. [31,8 mm] DIA.

HOLE FOR AIR SHIFT

POSITION INDICATOR

SHAFT

RUBBER (MOUNTED

BY CUSTOMER)

16.31 IN.* [414,3 MM] APPROX. ROAD

CLEARANCE

29 IN.* [736,6 MM] APPROX.

ROAD CLEARANCE

NOTE: DIMENSIONS MARKED WITH AN ASTERISK (*) MAY BE ALTERED TO FACILITATE INSTALLATION OF UNIT

CLOCKWISE INPUT ROTATION

Figure 2. Typical Pump Mounting on Vehicle Chassis