Gatlin, How to, Size select – Pump Solutions Group Neptune Polymaster User Manual

Page 3: Distribution head

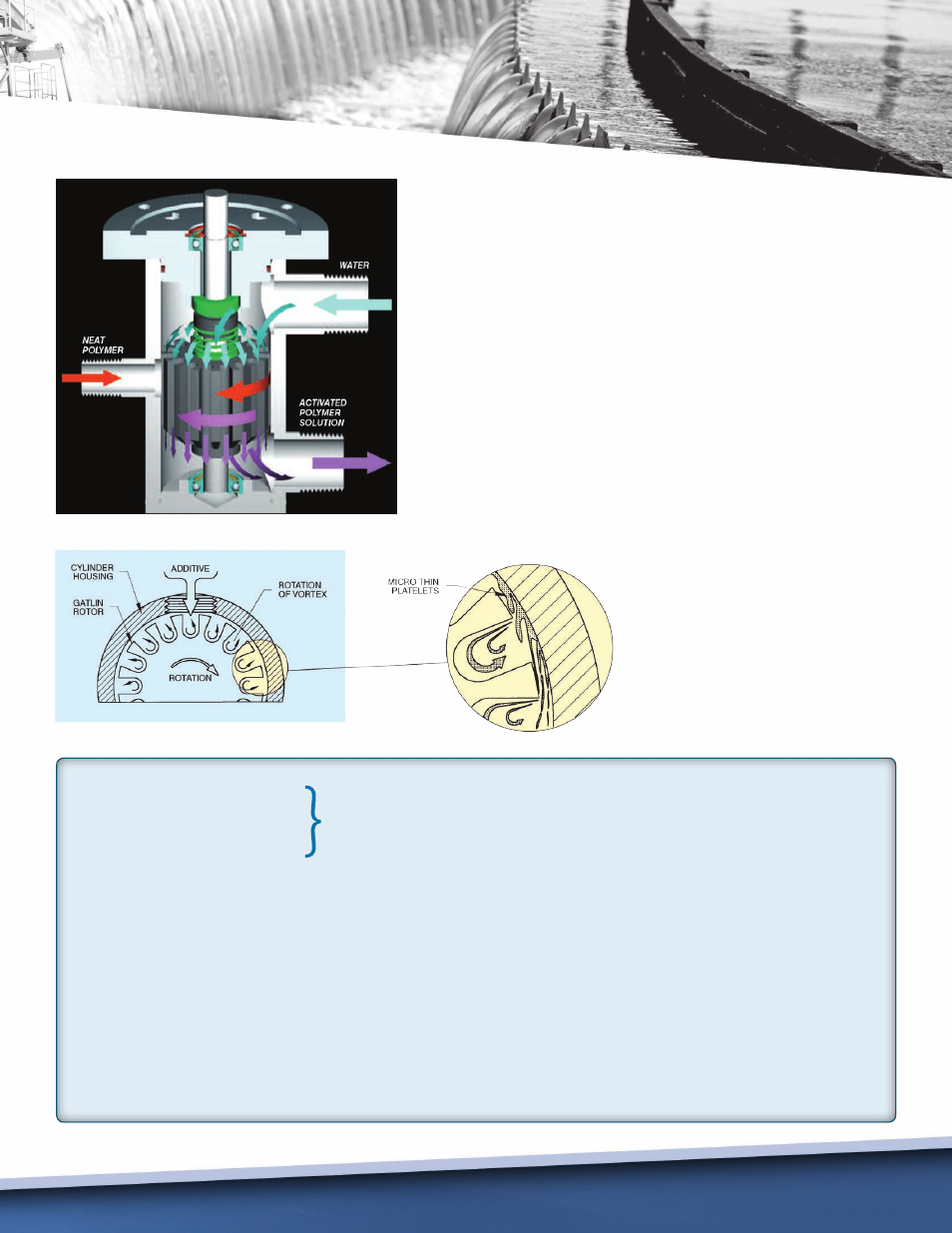

Gatlin

Distribution Head

The patented, motorized Gatlin distribution head hydraulically segments polymer

into ultra-thin film platelets, maximizing the polymer surface area exposed to

dilution water, providing maximum activation. Degree of activation is not affected

by fluctuating water pressures or dilution-water ratio changes.

How It Works

The Gatlin provides a rapid, high-energy initial introduction of polymer to water

followed by gentle, low-shear mixing in a multi-stage static mixer.

The rotating, slotted head operates at close tolerance to the inner wall of the

mixing chamber. The clearance does not permit fish eyes or gels to form. The

slotted rotor creates a series of high-velocity vortexes without the use of turbine

blades that can damage fragile polymer chains.

Superior performance proven repeatedly in side-by-side tests with other

blending machines.

1.

Determine the amount of neat polymer required. This will

determine the pump size.

2.

Determine the correct dilution ratio at which the polymer is

to be used. This will determine the Polymaster™ model.

Example: 9.5 lph (2.5 gph) of liquid polymer is required. The

desired application rate is a 0.5% solution (200:1 dilution).

Therefore, a pump 9.5 lph (2.5 gph) or greater is required.

The dilution water requirement is (200 x 9.5) 1,893 lph or

(200 x 2.5) 500 gph.

3.

Select correct Polymaster and pump combination.

Example: Decide if the unit is to be manual or automatic.

Assuming an automatic model is desired, select an

automatic Polymaster with greater than 1,893 lph

(500 gph) water capacity: the Model PAD-600 is selected.

Select a pump with a capacity greater than 9.5 lph (2.5 gph):

the 17 lph (4.5 gph) automatic pump (Model 107804A)

is selected.

Order Polymaster Model PAD-600 with pump

Model 107804A.

How to

Size

Select

&

Follow these easy steps to select the correct Polymaster

™

unit:

3