Dry polymer preparation system, Dynablend – Pump Solutions Group Neptune User Manual

Page 18

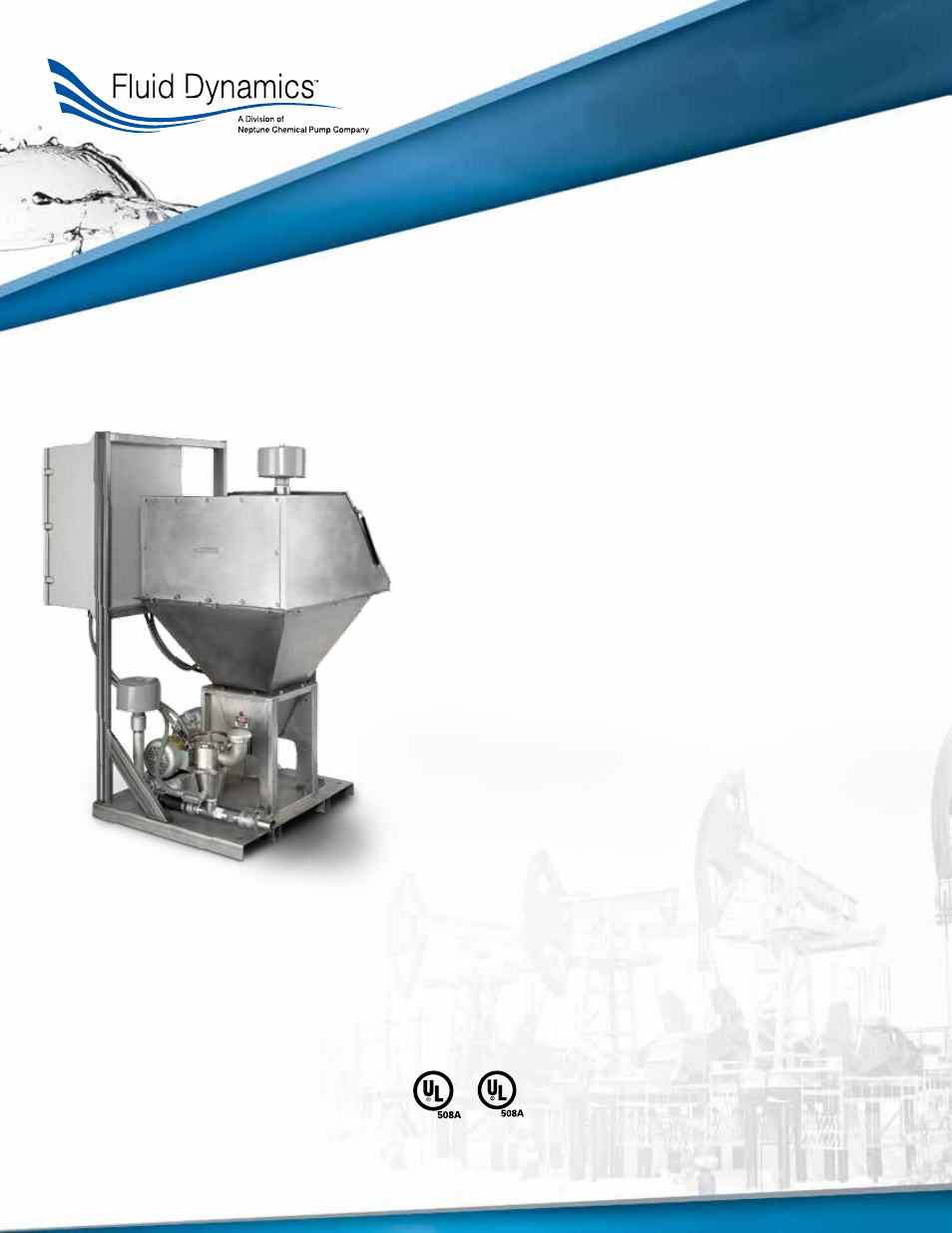

dynablend: dry Polymer

Preparation system

dynablend™

dry Polymer Preparation system

compact, high performance dry polymer preparation system utilizes a

negative pressure conveyance system to transport and disperse the dry

polymer prior to wetting.

Applications

•

Water/wastewater treatment

•

agriculture

•

oil and gas

•

Mining

•

sludge thickening and dewatering

•

Phosphorous removal

•

enhanced setting

•

coagulation and flocculation

•

Filter aids

•

thickening and dewatering in on-site treatment plants

•

dewatering of mud from vegetable washing/water recovery/re-use

•

Polymer flooding for enhanced oil recovery

•

refinery oil water separation

•

ore concentration

Features & Benefits

•

Vacuum induced, non-mechanical polymer conveyance

•

Wetting technology reduces plugging

•

Proven performance

•

assures thorough wetting of polymer for optimum performance

•

Proven quality

•

Prevents polymer build-up at volumetric feeder

•

Proven reliability

•

safer and cleaner operation

•

low life cycle cost

•

Flexibility to choose control features that best

meet the needs of a specific user

•

Handles extreme conditions, harsh environments

Technical Data

• Polymer transfer distance up to 20 ft (from the volumetric

feeder to the mix tank)

• 180-gallon stacked tank system

Performance Data

•

up to 12 lb./hr. dry polymer

Certifications & Associations:

C

18