Iii. replacement parts – Spencer Vacuum Cleaning Systems User Manual

Page 5

5

III. Replacement Parts

How to order replacement parts

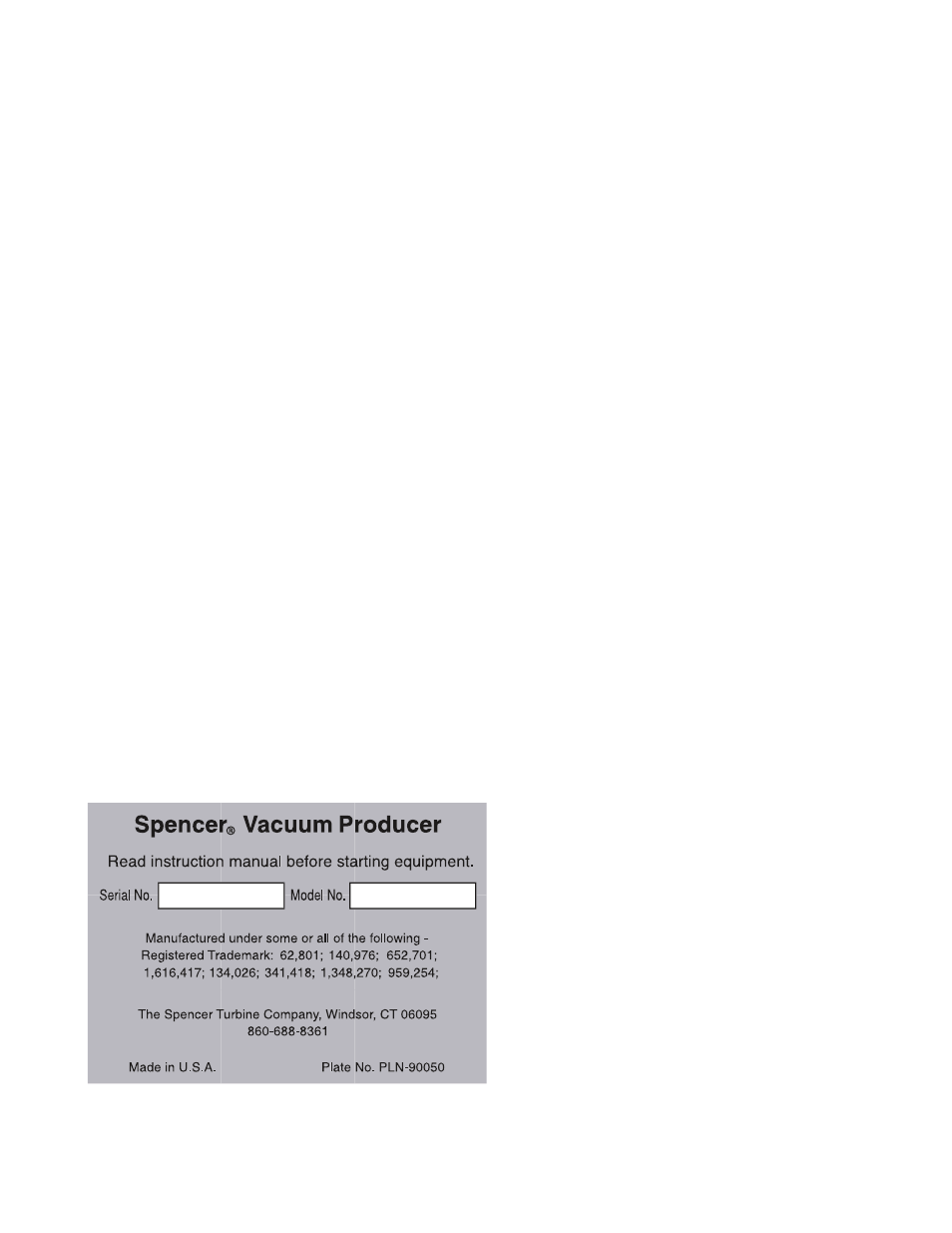

When ordering replacement parts, it is important that the infor-

mation you furnish to Spencer is correct and complete. Be sure

when reading nameplates that you obtain the correct information.

Record nameplate information on one of the typical nameplates

shown here and on the cover to use as a reference when ordering

parts. Remember, the more complete the information, the

quicker the order will be processed; incomplete information will

result in unnecessary delays and expense through callbacks.

When in doubt, consult the factory for further information.

To order replacement parts, furnish the following:

1. Record machine serial number and catalog/model number

from machine nameplate.

2. Record motor horsepower from motor nameplate.

3. Measure and record the casing diameter.

4. Refer to applicable illustration in the instruction manual and

locate needed item by its circled call-out number. Refer to

call-out list for nomenclature and record.

5. When ordering impellers and deflectors be sure to include

the letter designation shown on the applicable illustration. An

alternate method would be to count the number of impellers

from the end of the casing.

6. Include the form number from which you have extracted the

nomenclature. The form number is shown in the bottom right

corner of the cover page and will read AA, EE, etc.

The following are recommended spare parts:

Tubular bag separator.

Complete set of replacement bags.

Standard Overhung (refer to drawing on page 9 for item

numbers).

Item Number

Nomenclature

2

Division head packing

4

Rope packing

9

Interstage packing

12

End head gasket

15

Drive End motor bearing

19

Opposite Drive End motor bearing

Four Bearing Overhung (refer to drawing on page 11 for

item numbers).

Item Number

Nomenclature

1

Flexible coupling

5

Coupling End bearing

5A

Blower End bearing

6

Division head packing

14

Interstage deflector packing

16

End head gasket

18

Rope packing

21

Drive End motor bearing

23

Opposite Drive End motor bearing

Four Bearing Outboard (refer to drawing on page 13 for

item numbers).

Item Number

Nomenclature

2

Drive End motor bearing

3

Flexible coupling

10

Rope packing

18A

Outboard bearing(s)

20

End head packing

22

End head gasket

25

Interstage deflector packing

32

Division head packing

34

Inboard bearing

37

Opposite Drive End motor bearing

38 or 39

Metallic packing (if machine equipped with

packing box).

Typical Nameplate

When aligning a sleeve bearing motor with a machine, use the

following procedure:

1. The motor shaft must be level.

2. Position the motor so that when the rotor is pushed toward

the machine as far as it will go, there will be 0.030 clearance

between the ends of the machine and motor shafts (or the

alignment faces on the coupling hubs).

3. Proceed with the coupling alignment in accordance with

applicable instructions.