Service instructions – Bell & Gossett V58912B PSH Primary-Secondary Header Flanged & Threaded Connections User Manual

Page 2

5. Reassemble the two side sections, fitting the lower cap

into one of the two sections and then connecting the other.

6. Finish the assembly with the adhesive tape provided in the

box.

7. Complete with the two black head covers.

8. Fit the automatic air vent and the drain valve.

Recommended sealant: Superclear mastic.

SERVICE INSTRUCTIONS

There is no service required for the PSH.

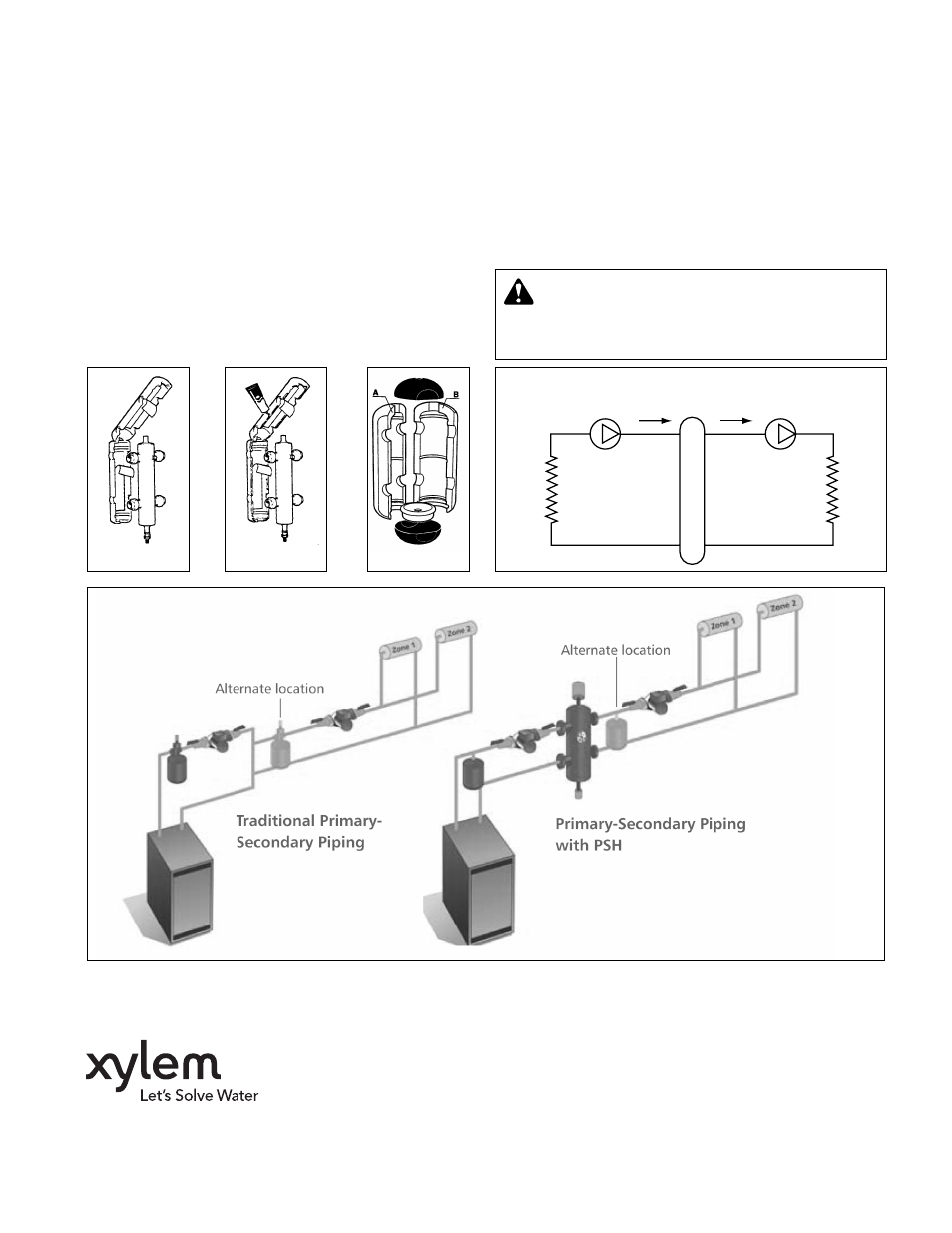

CAUTION: Corrosion or leakage of the PSH can cause

damage or injury. Periodically inspect the PSH for

signs of leakage or corrosion. If noted, PSH must be

replaced. Failure to follow these instructions could result in

property damage and/or moderate personal injury.

Procedure for installation and insulation

assembly on threaded models

1. Remove the protective strip from the adhesive surface. Re-

close the shells (See Illustration A).

2. If the hydraulic separator is used with chilled water spread

a thin layer of sealant on the edge of the insulation and

wait until the solvent evaporates (10 minutes approx.) and

then close it again (See Illustration B).

Procedure for installation and insulation

assembly on flanged models (up to 4")

1. Remove the two black head covers at the ends.

2. Open the two side sections and the lower cap.

3. Install the separator in the system.

4. Use the tape provided on insulation.

Illustration A

Illustration B

Illustration C

secondary

circuit

primary

circuit

Primary

Circuit

Flow

Secondary

Circuit

Flow

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V58912B May 2012