Bell & Gossett P58725B Series 1535C Close Coupled Centrifugal Pump User Manual

Page 5

5

REPLACEMENT PROCEDURE

With motor removed from the system, use the following

instructions to facilitate the replacement.

1. Use a strap wrench or rag to prevent the impeller from

turning with one hand and loosen the impeller nut with the

other.

2. Lift the spring retainer and the seal spring from the shaft.

Remove the compression ring from the seal collar by

inserting a small screwdriver underneath the ring and care-

fully applying an upward prying force. Remove the ring,

collar and the remaining seal components from the shaft.

NOTE: Seal assembly consist(s) of a stationary seal insert

and rotating seal assembly. Each of these components

must be replaced when replacing the mechanical

seal. NEVER REPLACE INDIVIDUAL COMPONENTS

SEPARATELY.

3. Using a clean, lint free rag, remove any debris that may

have accumulated on the seal recess.

4. Place the new seat retainer in the bracket seal recess.

Seat the thin rubber seat gasket in the recess and set the

ceramic seat insert atop the gasket. The ceramic has a top

side and bottom side. The bottom is identifiable by its

slightly recessed grooves. These grooves should face

downward toward the rubber gasket (gear gasket).

5. Lubricate the rubber bellows with soapy water. The entire

rotating seal assembly, which includes the carbon seal

ring, rubber bellows, seal ring retainer and compression

ring, is to be pushed onto the shaft as one unit. Do not

attempt to assemble the seal by placing the components

on the shaft individually. The notches in the seal ring

retainer should be aligned with the recesses found on each

side of the seal ring (rotating ring).

6. Press the rotating seal assembly on the shaft until the

carbon seal ring (rotating ring) makes contact with the

ceramic seat. Press down tightly. A screwdriver can be

used at several points along its periphery to provide a tight

and even fit. Press with the screwdriver – do not tap.

Tapping on the seal may break the ceramic or carbon

insert.

7. Place the seal spring and spring retainer on the shaft.

Next, place the impeller and lock washer. Thread the

impeller nut to the shaft and tighten to 17-22 ft.-lbs. Do

not overtighten.

8. Clean the pump body of excess debris. Place a new

gasket on the pump body; ensure that it sits flush against

the gasket surface.

9. Replace the motor by inserting the impeller in the pump

body and evenly tighten the eight capscrews.

10. Refer to the WIRING INSTRUCTIONS on the motor name-

plate or inside the conduit cover.

11. Follow the OPERATIONAL INSTRUCTIONS in this manual

to 1) check the PH of the system water, 2) to check the

rotation of the pump, and 3) to prime the pump and sys-

tem prior to starting.

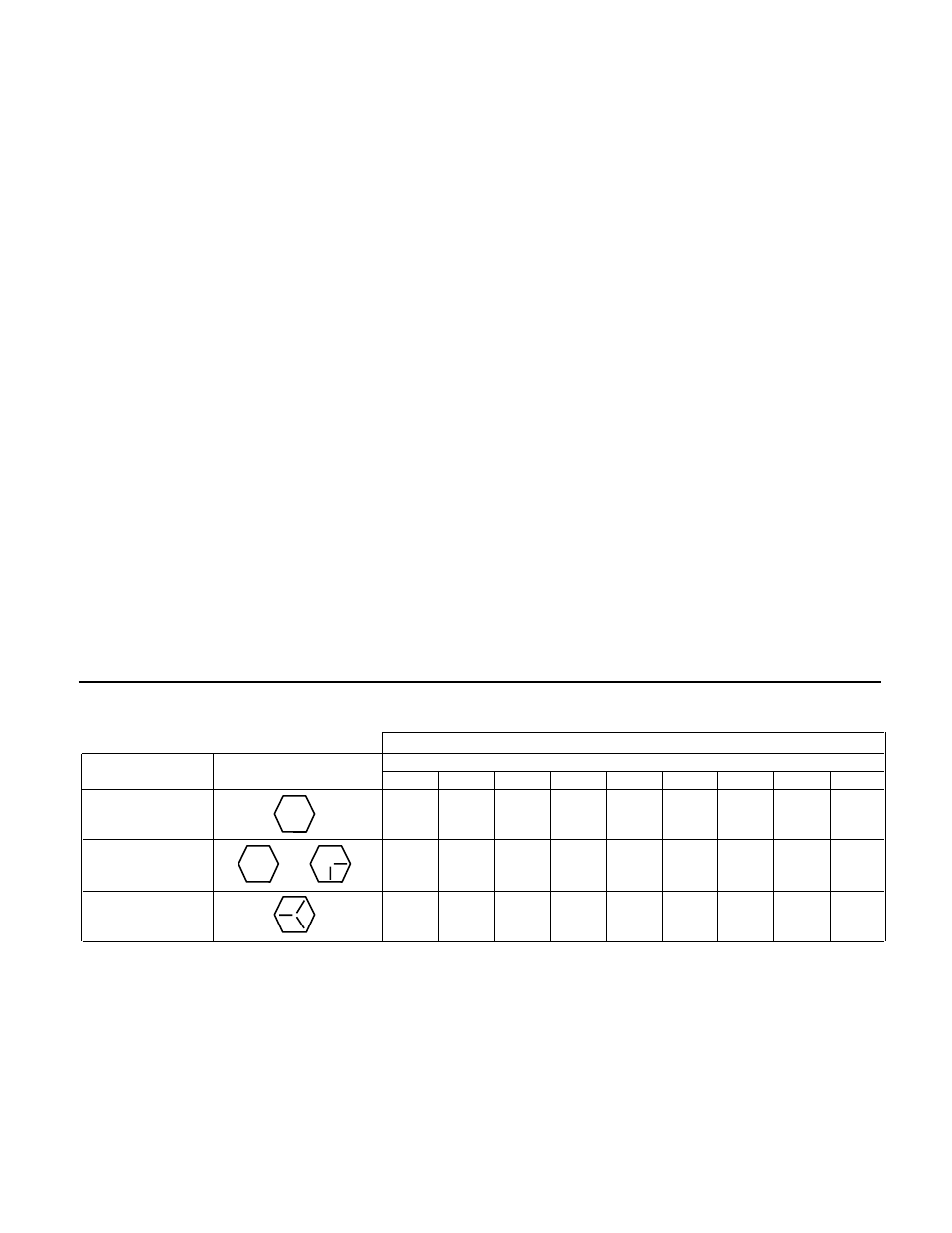

CAPSCREW TORQUE (FOOT-POUND)

CAPSCREW

HEAD

CAPSCREW DIAMETER

TYPE

MARKING

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

SAE Grade 2

6

13

25

38

60

120

190

210

300

Brass

Stainless Steel

or

4

10

17

27

42

83

130

200

300

SAE Grade 5

10

20

35

60

90

180

325

525

800