Caution – Xylem IM205 Vortex Series User Manual

Page 17

Vortex Installation, Operation and Maintenance Manual

15

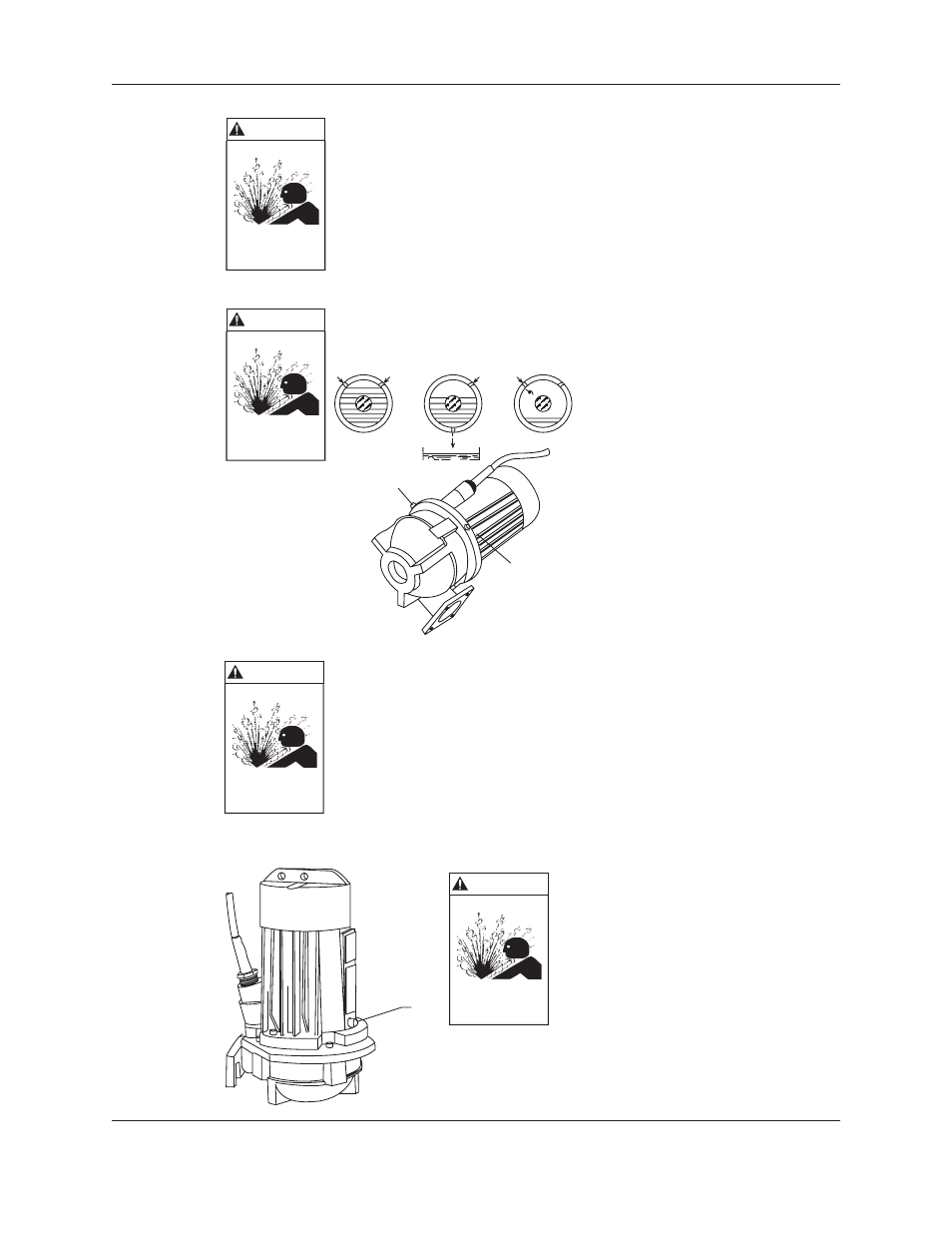

Oil Level

Put the pump in a horizontal position so that the 2 hexagonal socket screws

are on top and one at the bottom (see Figure 11). Unscrew the level plug

(1) and the vent plug (2).

The oil level should be at the lower side of the openings (see drawing). By

turning the pump a bit this should be visible. If not, fill up to the correct

level.

Always use the right kind of oil.

Oil Change

Collection, storage and removal of the oil should be done according to the

regulations of the local authorities.

Figure 10

When necessary replace the sealing rings.

Always use the right kind of oil. (See Figure 10).

Put the pump in a horizontal position so that one of the oil plugs is at the

bottom. Remove the vent plug (2). Put a receiving bin underneath the drain

plug (1). Remove the plug and drain the oil.

Rotate the pump so that the 2 openings are on top.

Refill the oil housing. The oil level should be at the lower side of the

openings. Replace the plugs.

Motor Housing

Unscrew the inspection plug of the motor

housing. Put the pump in horizontal

position with the inspection opening

downwards. If water is present it will run

out this way. A small amount of water,

due to condensation is permissible. More

water is an indication of leakage of the

seal or housing. Oil is an indication of

seal failure between motorhousing and oil

chamber. Motor chamber is air filled only.

Figure 11

Hazardous pressure can

cause personal injury or

property damage.

CAUTION

Hazardous pressure can

cause personal injury or

property damage.

CAUTION

2

1

2

A

1

B

2

1

C

1

2

Hazardous pressure can

cause personal injury or

property damage.

CAUTION

Routine Maintenance (continued)

1

Hazardous pressure can

cause personal injury or

property damage.

CAUTION