Iii. start up procedures – Xylem IM205 Vortex Series User Manual

Page 10

8

Vortex Installation, Operation and Maintenance Manual

III. Start Up Procedures

After unpacking the pump, carry out the following check points:

Delivery Check

Check for possible transport damage and especially check that the cable has not

been nicked or damaged.

Check for complete delivery.

When the delivery is incomplete or damaged, please contact your dealer

immediately.

Oil Level

Check the oil level (see Routine Maintenance section: Oil Level).

Power Supply

Before making the electrical connections, check if the line voltage and frequency are the

same as on the pump data plate.

For examples of electrical diagrams and pump cable coding, see appendix 1.

Cable Entry

Especially when the pump has been in storage for a long time, the cable gland should be

checked and if necessary tightened.

Motor Protection

The pump should always be connected to the line by means of a suitable motor protection

circuit breaker.

Overload protection must be provided in the panel.

Motor Check

If in doubt about the condition of the motor or cable, Megger test motor windings against

grounding wire.

The phase resistance against grounding wire should be at least 1 Mohm.

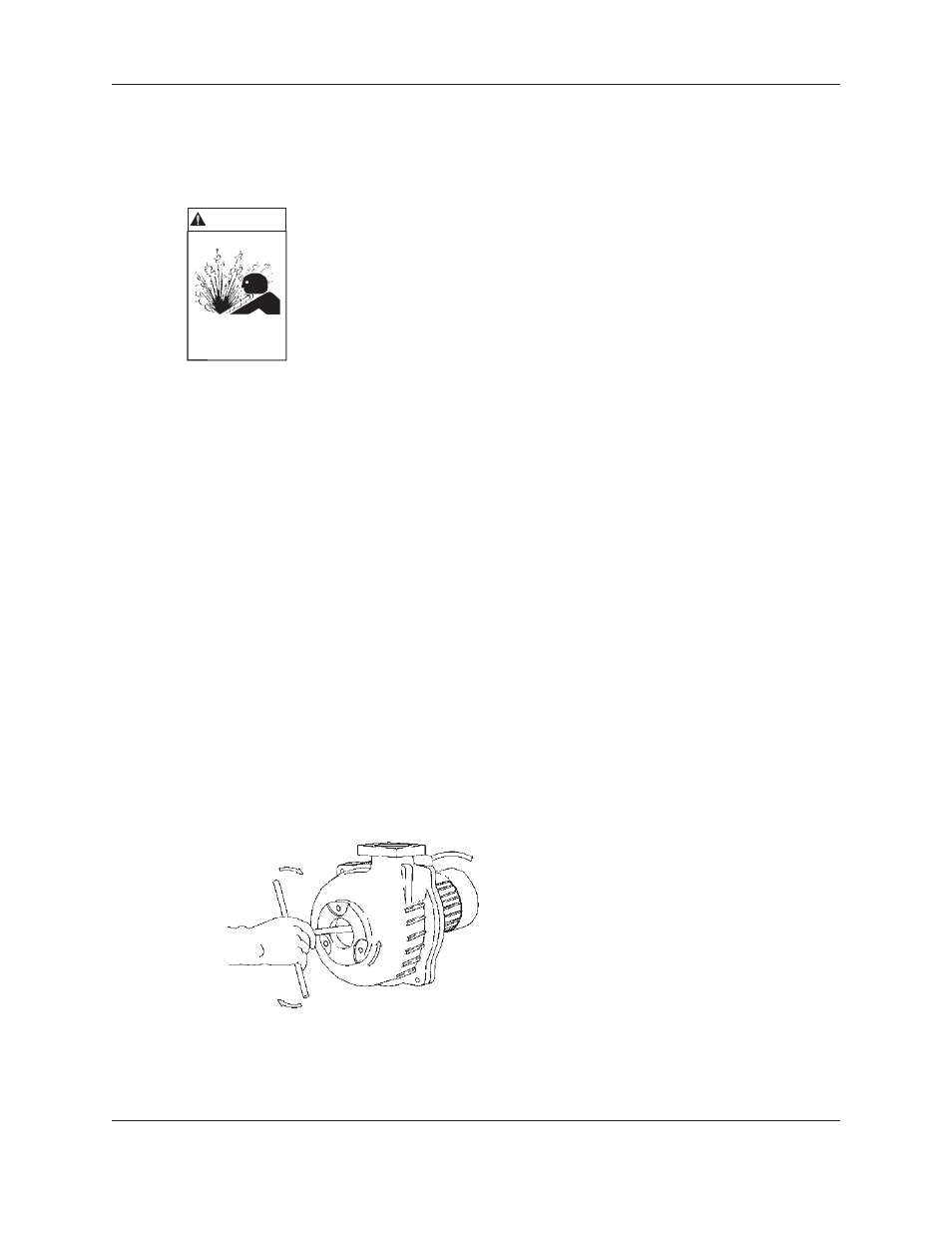

Figure 2

Turn the impeller clockwise by hand, using a proper socket wrench (see figure 6).

This should be possible without much force.

With this procedure sticking mechanical seal surfaces will be loosened smoothly.

Hazardous pressure can

cause personal injury or

property damage.

CAUTION

Start Up Procedures