0 changing a parameter value – Bell & Gossett S13213A MiniBooster Pumping Package User Manual

Page 8

8

APPENDIX 1 - PROGRAMMABLE PUMP

SEQUENCE CONTROL MODULE

1.1

The control system allows for intelligent pump control

while improving system reliability. Timers and relays

used in a conventional controller are integrated into a

single sequence controller. Because all of the timers

and relays are software, changes can be made to the

system operation without costly re-wiring. The work-

ing program is stored on a non-volatile EEPROM chip

that is an integral part of the unit. This means there is

no danger of ever losing a program due to power

losses.

1.2

A 7-day military time clock is standard. It is main-

tained by a super capacitor for a minimum of 8 hours

under a power loss condition. See section 2.4 for

instructions on how to set the clock.

1.3

The following page demonstrates a typical parameter

change. The programming of the module is very simi-

lar to setting a digital watch. As each unit will contain

a program that has been specifically designed for the

application, the actual data you will see will vary from

that shown in the example.

2.0 CHANGING A PARAMETER VALUE

2.1

Adjustable Settings

2.2

If any alarms are shown on the display of the pro-

grammable pump sequence control unit press the

ESC key to proceed with the following instructions.

2.3

Pressing the ESC key will cause the unit display to

show the following selections:

STOP – Do not use, this will stop the program

SET PARAM – Follow instructions as follows

SET CLOCK – Follow instructions as follows

PRG NAME – The name of the program loaded in the

module, such as: 2 pump with duty

Use the up and down arrow keys to select SET PARAM

and press the OK key to accept your selection.

2.4

If you wanted to set the time you would have selected

Set Clock instead. The time would have been set the

same as any other value in the module.

2.5

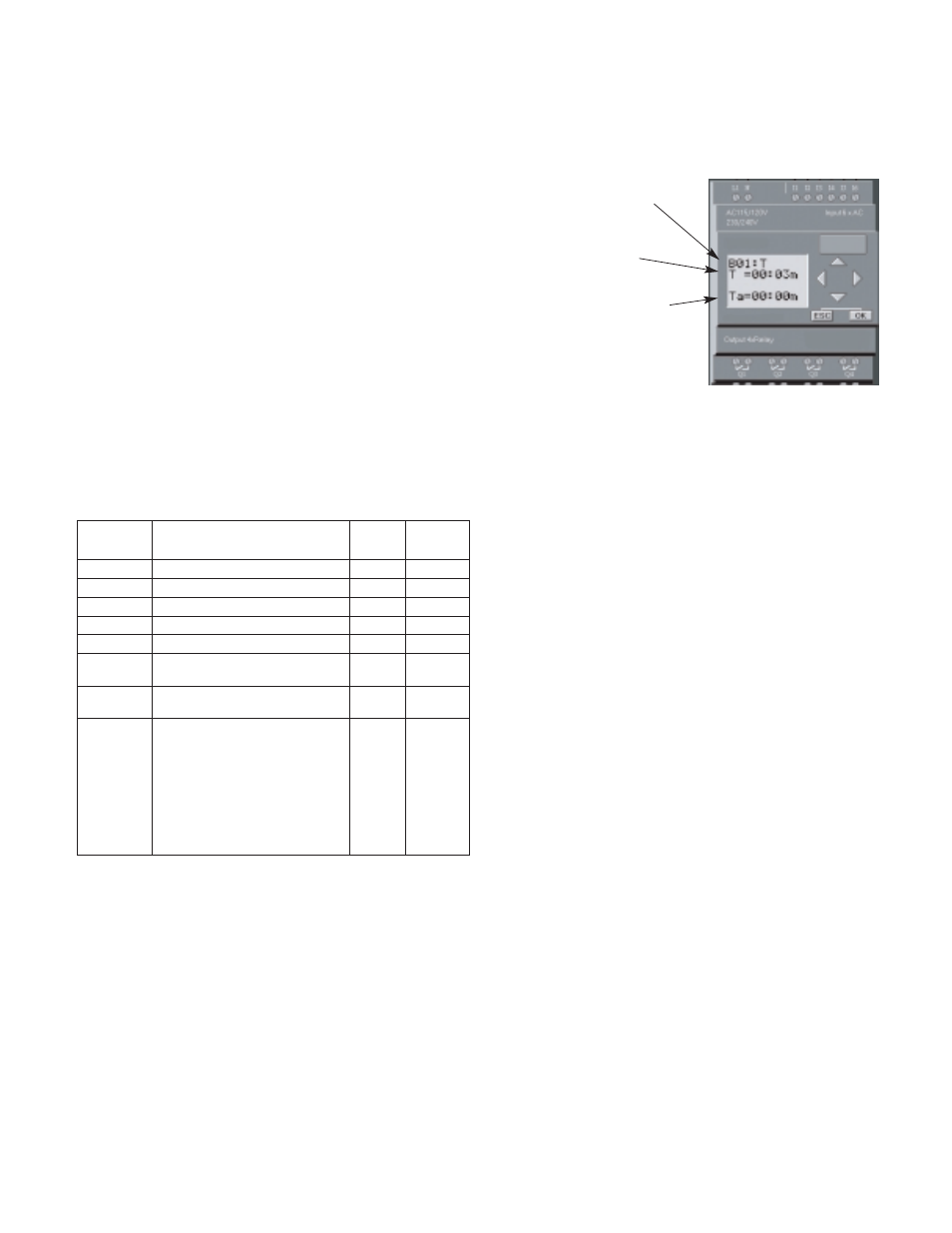

After selecting SET PARAM and pressing the OK key

the display will change as shown to the right.

The parameter number

is indicated here.

The preset value is

indicated here.

A live display of the

timer in question is

shown here. This can be

helpful if you just need

to see when a timer is

about to expire.

2.6

Press the Up and down arrow keys to select the

parameter you wish to change.

2.7

Press OK to edit the displayed parameter.

2.8

Press the left and right arrow keys to select the digit

you wish to change. Selected digit will flash.

2.9

Press the up and down arrow keys to change the

value of the selected digit as required.

2.10 Press OK to accept the change. Pressing the ESC

key instead of OK will abort and the changes will not

be saved.

2.11 Use the ESC key to return to the main screen. Each

time you press the ESC key you will back up one

level from where you are until you finally return to the

normal operating screen, which is the date and time

display.

Parameter

Default Variable

Number

Description

Setting

Range

B01

Lead Pump Minimum Run Timer

10 m

0-99 m

B02

Lag Pump Miimum Run Timer

10 m

0-99 m

B04

Lead Pump Start Delay Timer

1 s

0-99 s

B05

Lag Pump Start Delay Timer

5 s

0-99 s

B07

Pump Fail to Start Delay Timer

5 s

0-99 s

B12

Low Suction/Temp Pump

Shutdown Off-Delay Timer

5 s

0-99 s

B33

Low Suction/Temp Pump

Shutdown On-Delay Timer

5 s

0-99 s

B36

Duty Cycle Alternation

Enable/Disable Switch

OFF

OFF/ON

When setting item B36 the OFF

selection allows the lag pump to

stage on during periods of high

demand. When B36 is set to ON

the lag pump is a standby pump

which will turn on in the event the

lead pump fails.