Bell & gossett, Instructions for pump repair, Periodic inspection – Bell & Gossett P15776H Little Red Booster Pumps User Manual

Page 4

Bell & Gossett

© COPYRIGHT 1982, 2004 BY ITT INDUSTRIES, INC.

PRINTED IN U.S.A. 1-04

USA

Bell & Gossett

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-9052

http://www.bellgossett.com

INTL.

Bell & Gossett / Export Dept.

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-8366

http://www.bellgossett.com

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario,

N1H 1T1, Canada

Phone: (519) 821-1900

INSTRUCTIONS FOR PUMP REPAIR

1. Follow steps 1 through 4 of section titled “REMOVAL OF

PUMP FROM EXISTING SYSTEM FOR REPLACEMENT.”

2. Loosen the four capscrews that hold the motor housing to

the pump body. Remove these screws and remove the

housing from the pump body.

3. Place the pump on a flat work surface and insert the plastic

assembly tool (furnished with the repair kit) into the rear

motor housing coverplate middle horizontal vent holes.

Push forward until it engages the rotor cooling fins. This will

lock the rotor allowing removal of the impeller.

4. Remove the impeller nut – left hand thread! – from the pump

shaft. Remove the impeller and rotating seal assembly.

5. Clean the ceramic seat with a clean rag and inspect for

grooving or cracks. If it shows no grooving or cracks, it

may be cleaned and reused.

6. If the ceramic is to be replaced, the face plate must be re-

moved from the motor housing. Remove it by gently pry-

ing it away from the motor housing.

7. Remove the damaged ceramic seat and boot if necessary.

Reinstall new parts in the face plate recess and reposition

the face plate on the motor housing. Gently tap the face

plate evenly around its diameter driving it into the recess

provided in the motor housing.

INSTRUCTIONS FOR PUMP REPAIR

8. Press the rotor fully forward with the plastic assembly

tool. Clean the shaft and sleeve before installing the seal.

9. Press the replacement carbon seal assembly firmly into

the recess in the back side of the impeller.

10. Assemble the seal/impeller assembly to the pump shaft

by pushing the rotor fully forward with the plastic assem-

bly tool. Then slide the seal/impeller assembly onto the

pump shaft until the seal face contacts the ceramic seat.

11. Continue holding the rotor fully forward with the assembly

tool. Install and torque the impeller nut – left hand thread!

– to 15 in-lb (0.17 Kg-m) torque.

12. Clean the recess in the pump body and install a new body

gasket.

13. Install the pump in the body and secure with four cap-

screws. Apply torque evenly in a criss cross pattern to 40

in-lb (0.46 Kg-m) increments to a torque of 80 in-lb (0.92

Kg-m).

14. Reinstall into the system using new flange gaskets. For

instructions, see sections “PUMP INSTALLATIONS”

through and including “LUBRICATION.”

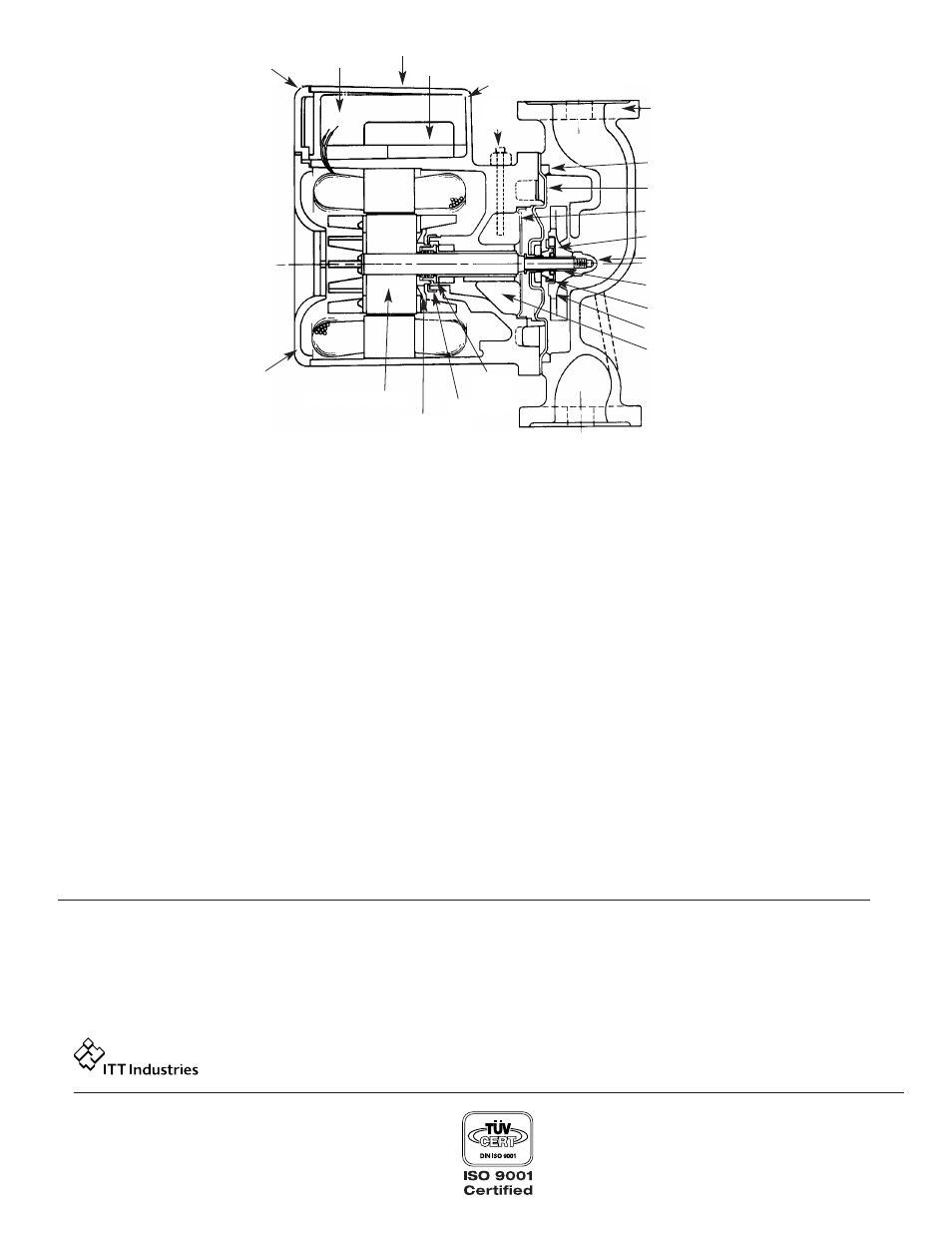

CONDUIT BOX

COVER

CAPACITOR

NAME PLATE

CAPACITOR RETAINER

STATOR & HSG. ASM.

OIL

HOLE

PLUG

BODY

BODY GASKET

COVERPLATE ASM

WICK COVERPLATE

IMP. CUSHION

IMP. NUT

SHAFT SLEEVE

SEAL ASM

IMPELLER

PERMAWICK

THRUST

COLLAR

OIL RETAINER

THRUST DRIVER

MOTOR HSG. COVER

FIG. 6

ROTOR & SHAFT ASM.

PERIODIC INSPECTION

Bell & Gossett Booster Pumps are designed to provide years of

trouble free service. It is recommended that periodic inspec-

tions be made to check for potential problems with the pump. If

PERIODIC INSPECTION

any leakage or evidence of leakage is present repair or replace

the unit.