Pump installation, Typical installation schematic – Bell & Gossett P15776H Little Red Booster Pumps User Manual

Page 3

3

PUMP INSTALLATION

Locate the pump so there is sufficient room for inspection, main-

tenance and service. Bell & Gossett recommends the installa-

tion of service valves on the suction and discharge of all circu-

lators to facilitate servicing or replacement of the circulator

without draining the system.

Install suction and discharge flanges on the pipe ends. The

use of Teflon

®

* tape sealer or a high quality thread sealant is

recommended.

Be sure to minimize any pipe-strain on the pump. Support the

suction and discharge piping by the use of pipe hangers near

the pump. Line up the vertical and horizontal piping so that the

bolt-holes in the pipe flanges match the bolt-holes in the pipe

flanges. [DO NOT ATTEMPT TO SPRING THE SUCTION OR

DISCHARGE LINES IN POSITION. THIS MAY RESULT IN

UNWANTED STRESS IN THE PUMP BODY, FLANGE CON-

NECTIONS AND PIPING.] The code for Pressure Piping

(ANSI B31.1) lists many types of support available for various

applications.

Bell & Gossett flange gaskets must be installed between the

Little Red pump body flanges and the suction and discharge

pipe flanges. Suitable fasteners for this connection are also

supplied in the Bell & Gossett fastener pack.

Apply torque in even increments to both flange bolts until a

value of 175 in-lbs (2.01 Kg-m) is reached. Both the suction

and discharge flanges must be torqued in this manner.

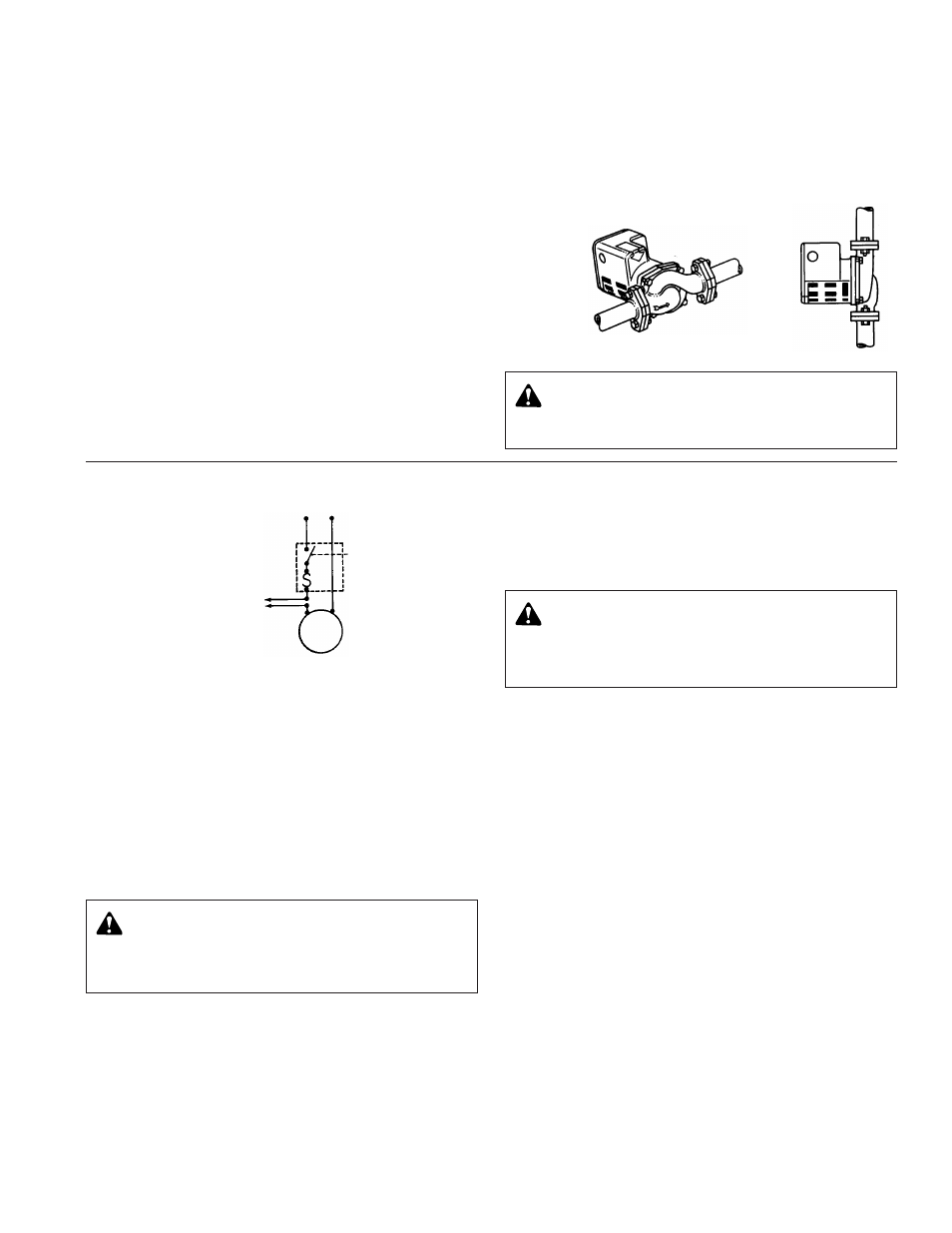

MODE OF DISCHARGE

The Little Red Booster Pump can be installed to discharge up

or down, horizontally left or right, but the oiling port must

always be in the twelve o’clock position (on top). Arrow on

body must point in direction of flow.

TYPICAL INSTALLATION SCHEMATIC

POWER SOURCE 115 Volt. 60 Hz.1ø

ELECTRICAL WIRING

A. Loosen screws securing the conduit box (wiring compart-

ment) cover, removing screws and cover.

B. Select one of the two holes in the side of the conduit box

and wire the motor to a 115 volt, 60 hertz, single phase

power source with number 14 AWG copper electrical wire.

Refer to your local code for wiring restrictions. Plug the

unused hole in the side of the conduit box with the plug

provided.

C. Connect the ground wire to the inside of the conduit box

with the green screw provided.

NOTE: Supply and grounding wires must be suitable for at

least 90°C (194°F).

ELECTRICAL CHARACTERISTICS

Model LR-20BF is rated at 1/20 HP, 115 volts, 1.1 F.L. amps,

60 HZ, 1ø (single phase), 2900 RPM.

Model LR-15B is rated at 1/12 HP, 115 volts, 1.75 F.L. amps,

60 HZ, 1ø (single phase), 3150 RPM.

Little Red Booster Pumps are protected with an inherent over-

heating device and do not require external overload protection.

SYSTEM PREPARATION

Prior to pump start up, closed heating and cooling systems

should be cleaned, drained, and refilled with clean water.

System ph must be maintained between 7 and 9.

Pressurize the pump body slowly while checking for leaks at

all gasketed joints.

PRIMING

Do not run the pump dry. These pumps must be filled with

liquid before being placed in service. Air should be vented

from the system by means of an air vent located at a high

point in the system.

LUBRICATION

All new Bell & Gossett Little Red Booster Pumps are thoroughly

tested at the factory and have been enhanced with a superior

lubrication system which requires a minimum of attention. Please

refer to the recommended lubrication instructions noted below

for the type of pump service required.

1. At installation: Pumps have been factory lubricated and do

not require additional lubrication at start-up.

2. Heating system operation: Pumps should be lubricated at

the start of every heating season. Add one tube (5cc) of

Bell & Gossett P15775 lubricating oil.

3. Continuous duty: Pump should be lubricated every six (6)

months. Add one tube (5cc) of Bell & Gossett P15775 lubri-

cating oil.

NOTE: In lieu of genuine Bell & Gossett P15775 lubricating

oil, use one teaspoon of Mobile 1, SAE 5W-30, motor oil as

required.

IMPORTANT: Over oiling of the pump will result in the

overflow of oil from the oil reservoir.

WARNING: Electrical Shock Hazard

Disconnect and lockout the power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

WARNING: Electrical Shock Hazard

Be certain that all connections are secure and the

conduit box cover is closed before electrical power is con-

nected. Failure to follow these instructions could result in

serious personal injury or death.

FIG. 4

RIGHT OR

LEFT

UP OR

DOWN

FIG. 5

PUMP

MOTOR

FUSIBLE DISCONNECT

OR CIRCUIT BREAKER

BY OTHERS

PUMP MOTOR

INHERENTLY

PROTECTED

TO REMOTE

CONTROL

IF REQUIRED

WARNING: Hot Water Leakage Hazard

Pressurize the pump body slowly while checking for

leaks at all joints with gaskets. Failure to follow these

instructions could result in serious personal injury and/or

property damage.

*Teflon

®

is a registered trademark of E.I. DuPont de Nemours and Company.