Xylem IM228 R03 Model e-SV (esv) User Manual

Page 9

9

WARNING

WARNING

WARNING

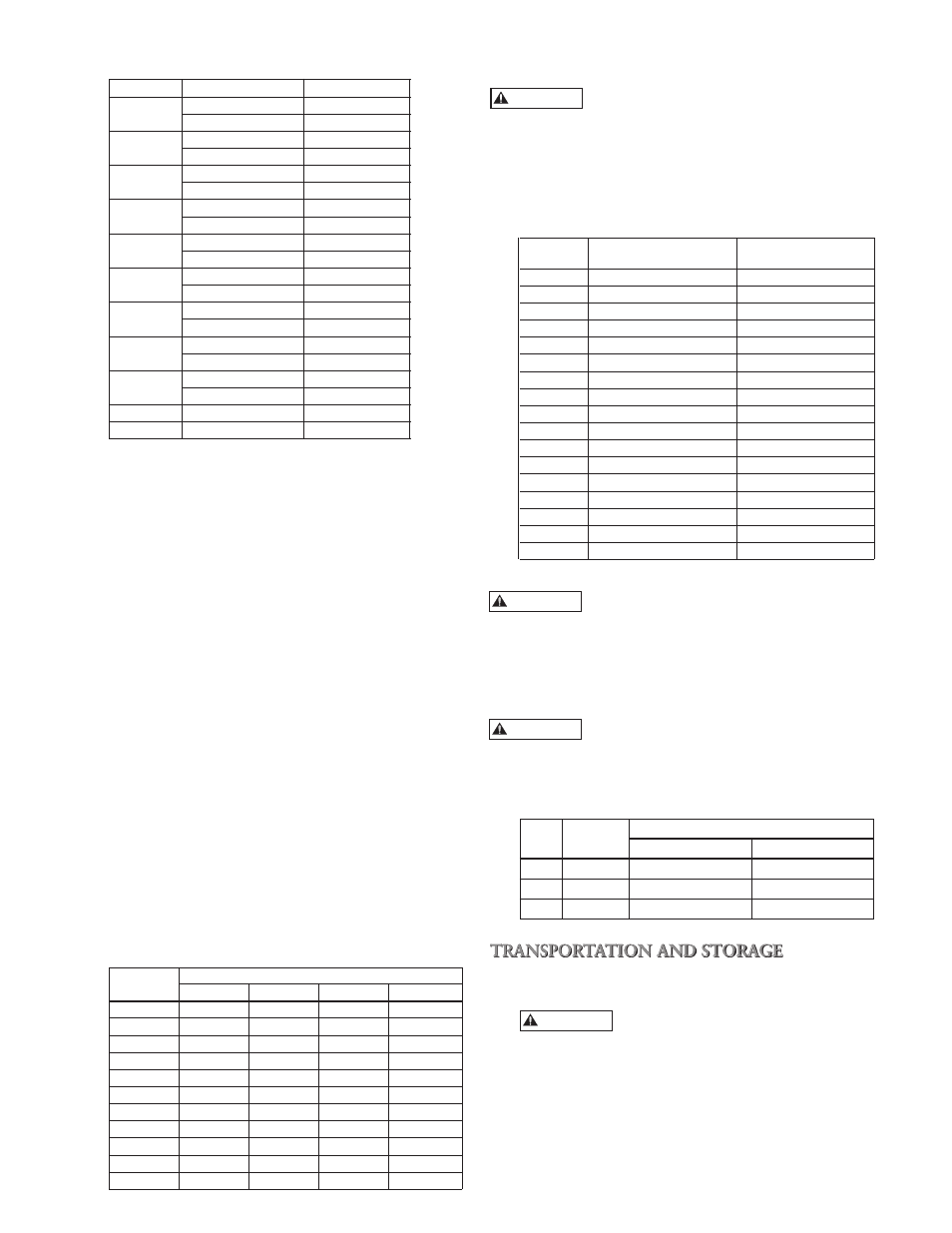

4. MAXIMUM OPERATING PRESSURE

(staging at 3500 RPM)

Pump

Stages

PSI / Bar

1SV

1-29

362 / 25

30

580 / 40

3SV

1-23

362 / 25

24-30

580 / 40

5SV

1-23

362 / 25

24-27

580 / 40

10SV

1-14

362 / 25

15-20

580 / 40

15SV

1-11

362 / 25

12-15

580 / 40

22SV

1-11

362 / 25

12

580 / 40

33SV

1-6

362 / 25

7-10

580 / 40

46SV

1-5

362 / 25

6-10

580 / 40

66SV

1-5

362 / 25

6

580 / 40

92SV

1-5

362 / 25

125SV

1-6

362 / 25

NOTE: Oval flange (1-22SV) maximum working

pressure is 232 psi (16 bar).

5. TEMPERATURE CAPABILITY

The e-SV pump is capable of pumping liquids within

the below temperature range:

Standard Seal

1SV-22SV

-22°F to 250°F (-30°C to 120°C)

33SV-125SV

-22°F to 250°F (-30°C to 120°C)

High Temperature Seal

1SV-22SV

-22°F to 340°F (-30°C to 171°C)

33SV-125SV N/A

NOTE: In order to provide adequate cooling for the

electric motor, the ambient temperature must

be 32º F to 104º F and the relative humidity at

104º F must not exceed 50%.

For temperatures above 104º F and for installations

sites located at elevation in excess at 3000 feet above

sea level it may be necessary to derate the motor

performance. Please contact your distributor/dealer for

assistance.

6. MINIMUM NOMINAL FLOW RATE

To prevent overheating of the internal pump com-

ponents, make sure that a minimum water flow is

always guaranteed when the pump is running.

For continuous operation the minimum flow rate

recommended is specified below.

Pump Size

Minimum Flow GPM

3500 RPM 1750 RPM 2900 RPM 1450 RPM

1SV

2

1

2

1

3SV

3

2

3

2

5SV

7

4

6

3

10SV

9

5

8

4

15SV

18

9

15

7

22SV

21

11

18

9

33SV

35

18

8

4

46SV

40

20

10

5

66SV

70

35

14

7

92SV

100

50

20

10

125SV

128

64

106

53

NOTE: If this cannot be achieved, then a bypass/

recirculate line is recommended.

Do not run the pump against a closed dis-

charge for longer than a few seconds.

7. NUMBER OF STARTS PER HOUR

For electric pumps coupled to motors supplied by

Goulds Water Technology, the maximum number

of work cycles (starts and stops) in one hour are as

follows:

HP

Max. Starts Per Hour*

Min. Run Time

Between Starts (sec)

0.5

24

120

0.75

24

120

1

15

75

1.5

13

76

2

12

77

3

9

30

5

8

83

7.5

7

88

10

6

92

15

5

100

20

5

110

25

5

115

30

4

120

40

4

130

50

3

145

60

3

170

75

3

180

* For more details, refer to technical manual.

If you use a different motor from the

standard one supplied by Goulds Water

Technology, please consult with the motor manu-

facturer to find out the maximum number of work

cycles allowed.

8. POWER SUPPLY REQUIREMENTS

Make sure that the supply voltages and

frequencies are suited to the characteristics

of the electric motor. Check the motor rating plate.

In general, the supply voltage tolerances for motor

operation are as follows:

U

N

Hz Phase

V

±%

60

1

230

10

60

3

230 / 460

10

60

3

460

10

1. TRANSPORTATION AND HANDLING OF

PACKED PRODUCT

The e-SV pump is packed in cartons

or wooden crates having different

dimensions and shapes.

Some cartons (the supporting base is made of

wood) are designed to be transported and handled

in the vertical position. Other cartons, as well as

the wooden crates, are designed to be transported

and handled in the horizontal position. Protect the

product against humidity, heat sources and mechani-

cal damage (collisions, falls, ...). Do not place heavy

weights on the cartons.

WARNING