X 16 at least 1 – Bell & Gossett DN0147D HS Underground Condensate and Boiler Feed Units Series UHM User Manual

Page 6

6

PUMP SER

VICE INSTRUCTIONS FOR UNDERGROUND CENTRIFUGAL PUMPS

Vertical mounting puts motor above floor dirt and water.

These instructions are for pump disassembly. The mechanical

seal can be replaced without complete pump disassembly as

detailed on the prior page.

1. Close inlet gate valve and operate pump momentarily to

remove as much liquid as possible from pump. Close dis-

charge line gate valve.

2. Shut-off and lock out power.

3. Make sure unit is cool enough that pump can be handled safely.

4. Loosen the discharge pipe. Assure that pressure is relieved

per caution note.

5. Disconnect motor leads, conduit and discharge pipe.

6. Remove coverplate and pump assembly.

7. Remove discharge connection and tubing.

8. Remove capscrews holding volute and lower bearing head.

9. To remove impeller from motor shaft proceed as follows:

a) Remove self locking capnut and washer or self locking cap-

screw and washer.

b) Hold end of shaft opposite pump with suitable tool and

back impeller off with a rectangular bar or other flat tool

inserted between the vanes of the impeller.

10. Remove motor from motor support (half of the flexible cou-

pling will come away with the motor) and set aside.

11. Remove remaining part of flexible coupling. Use puller.

12. Remove grease coverplate from bearing support.

13. Remove the snap-ring from above the bearing.

14. Remove the four capscrews that hold the bearing support.

15. Insert two screws

3

/

8

x 16 at least 1

1

/

2

" long, into the tapped

holes in the flange around the bottom of the bearing support,

and the bearing support by turning both screws evenly, or by

alternating half-turns.

16. With the bearing support freed, remove the stationary part of

the seal, the slinger, and the bearing from the bearing support.

Remove the old gasket.

17. Remove bearing (note: bearing is shielded on lower side).

18. Remove rotating part of seal from shaft. Remove collar when

replacing shaft only.

19. Reassemble pump using new gaskets, reversing procedure

and following mechanical seal replacement steps described

on prior page.

20. When replacing lower bearing, remove lower carbon bearing

from lower bearing head and install new bearing.

Note: If lower bearing is made of bronze, then a complete new

lower bearing head assembly is required.

21. Reconnect pump bleed line and motor wiring.

22. Slowly open inlet gate valve. See warning.

23. Jog to check motor rotation. See caution.

CAUTION:

PRESSURIZED SYSTEM

Operating system may contain very hot water under

pressure. Close inlet and open drains before servicing.

When servicing,

loosen screws and move components to

assure pressure is relieved before

removing screws. Keep

drains open during servicing. Failure to follow these instruc-

tions could result in injury or death.

CAUTION:

HOT SURFACE

Surfaces are hot when system is in operation. Do not

touch hot receiver, let unit cool before servicing. Failure to

follow these instructions could result in serious injury or

death.

WARNING:

HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

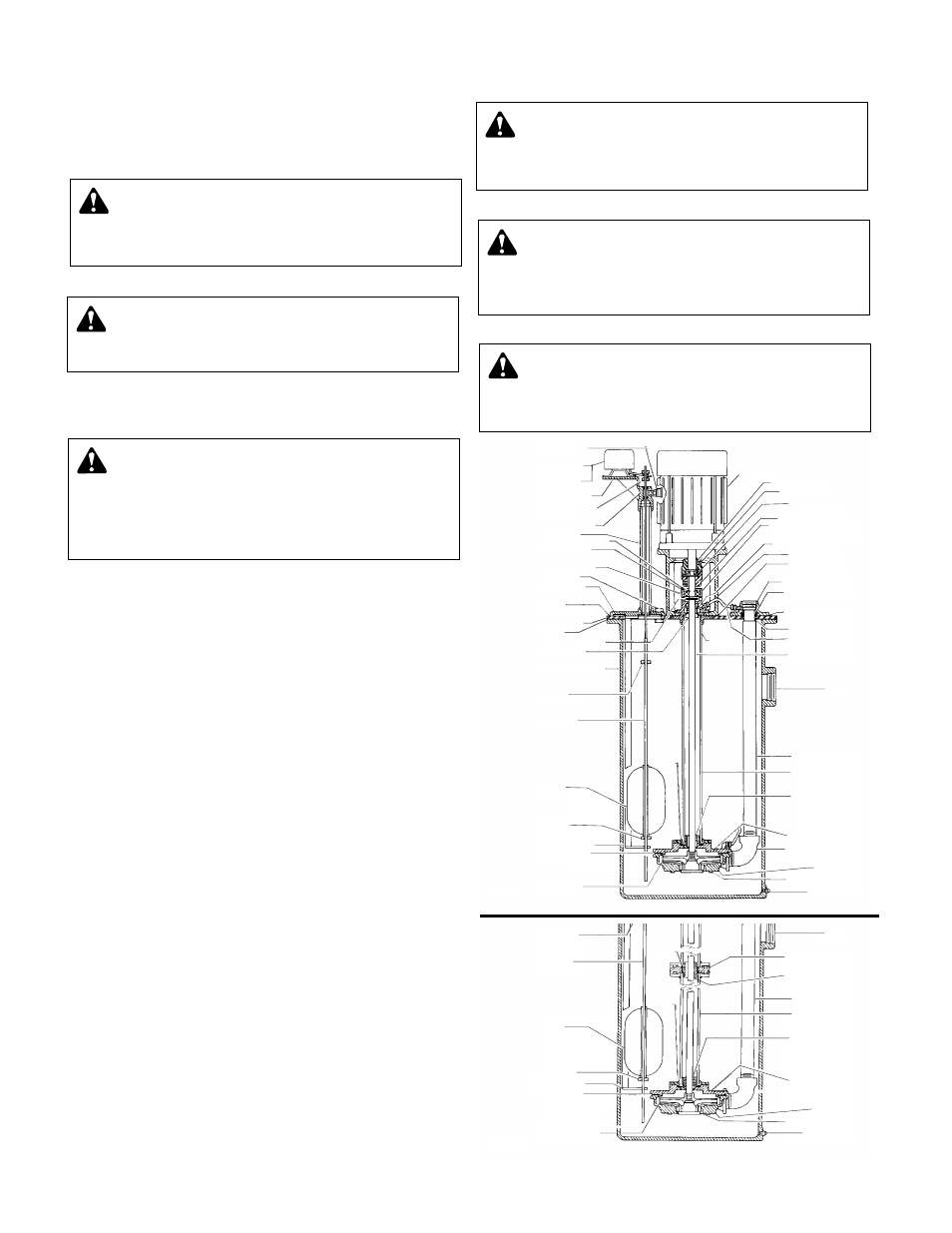

COLLAR

FLOAT STOP

2DPU02

2DPU04

FLOAT ROD

FLOAT

COLLAR

FLOAT STOP

FLOAT ROD GUIDE

GASKET CASE

IMPELLER

BRONZE ENCLOSED

ORIFICE

ORIFICE

DRAIN PLUG

CASE RING BRASS

CASE

DISCHARGE ELBOW

LOWER BEARING

HEAD

PUMP SUPPORT

COLUMN. PILOTED

DISCHARGE PIPE

INTERMEDIATE

BEARING HOUSING

WHEN USED

INLET

DRAIN PLUG

CASE RING BRASS

CASE

INTERMEDIATE

BEARING OIL-LESS

WHEN USED

LOWER BEARING

OIL-LESS

DISCHARGE ELBOW

LOWER BEARING

HEAD

LOWER BEARING

OIL-LESS

PUMP SUPPORT

COLUMN. PILOTED

DISCHARGE PIPE

INLET

IMPELLER SHAFT

STAINLESS STEEL

SEAL LUBRICATING

ASSEMBLY (WATER)

"O" RING

DISCHARGE FLANGE

EXPANSION JOINT

GASKET

DISCHARGE FLANGE

DISCHARGE FLANGE

GASKET

MOTOR SUPPORT

MOTOR SUPPORT

MECHANICAL SEAL

THRUST BALL BEARING WITH

SINGLE SEAL AND PROVISION

FOR RELUBRICATION

FLEXIBLE COUPLING

CUSHION SPIDER

MOTOR

GREASE CUP

FLOAT SWITCH

AUTOMATIC

ALTERNATOR

DUPLEX UNITS ONLY

SWITCH BRACKET

COLLARS (2)

SWITCH DRIP

VAPOR SEALS (2)

PIPE NIPPLE

RETAINING RING SHAFT

BEARING COVER

BEARING HOUSING

AIR VENT

CONTROL BASE

GASKET

CONTROL BASE

COVER PLATE

GASKET

RECEIVER

SLINGER

STOP COLLAR

MECHANICAL SEAL

RECEIVER CAST IRON

COLLAR

FLOAT STOP

FLOAT ROD

FLOAT

ORIFICE

COLLAR

FLOAT STOP

FLOAT ROD GUIDE

GASKET CASE

IMPELLER

BRONZE ENCLOSED

ORIFICE

KEYS (2)

SET SCREWS (2)

CAUTION:

DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation.

Failure to follow these instructions could result in serious

injury or death.

CAUTION:

DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR

Inspect pump seal regularly for leaks Replace as required.

Failure to follow these instructions could result in serious

injury or death.

WARNING:

EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.