Description, Representative piping diagrams – Bell & Gossett DN0147D HS Underground Condensate and Boiler Feed Units Series UHM User Manual

Page 2

2

DESCRIPTION

Series UH condensate units have one (simplex) or two (duplex)

pumps which are controlled by float(s) switch or mechanical

alternator switch in the receiver.

These pump return accumulated condensate to the boiler feed

system.

Series UHM boiler feed units have one (simplex) or two

(duplex) pumps which are controlled by boiler system con-

trollers. Series UHM receivers are sized to provide for accu-

mulating system surges of condensate. Water makeup valves

are also included to insure that water is always available to

meet boiler demands.

Receivers are non-code cast iron.

PRELIMINARY INSPECTION

Assure that there is no shipping damage.

Assure that nameplate ratings agree with job specifications

and actual conditions.

HANDLING

Use care in installing unit.

LOCATION

Place unit for easy access to all parts. Allow adequate space

for servicing. Check ambient conditions.

NOTICE / TEMPERATURE

LIMITS

Motors are designed to operate in 104ºF max. ambient.

Insulate or ventilate as required.

PIPING (General)

Pipe the unit per the Elementary Piping Diagram. Locate and

support piping so as not to load the pump discharge.

PIPING (Returns)

Gravity return lines from the system must be properly pitched

down to unit inlet. Returns must also be trapped to prevent

steam entry into the unit. An inlet basket strainer is recom-

mended.

PIPING (Vent)

Install a vent pipe to atmosphere. Pipe to be size of vent port

on unit. Do not restrict or reduce vent opening or exceed 20

inch vertical height unless an overflow connection is provided.

FLOAT SWITCHES AND MECHANICAL ALTERNATORS

The floats which operate these switches are factory set but

can be field readjusted as required.

Adjustment is made by removing the float switch as an

assembly and readjusting the stop collars on the float rod.

Setting should utilize as much of the tank volume as practical.

Settings should avoid “short cycling” of the pump. See page 3

for detailed instructions.

ELECTRICAL WIRING & CONTROLS

Connect power wiring per NEC. Recheck nameplate vs. speci

-

fications and conditions. All single phase motors have internal

thermal protection.

Three phase motors must use starters with properly sized

overload relays. Overload relays furnished are designed for

manual reset.

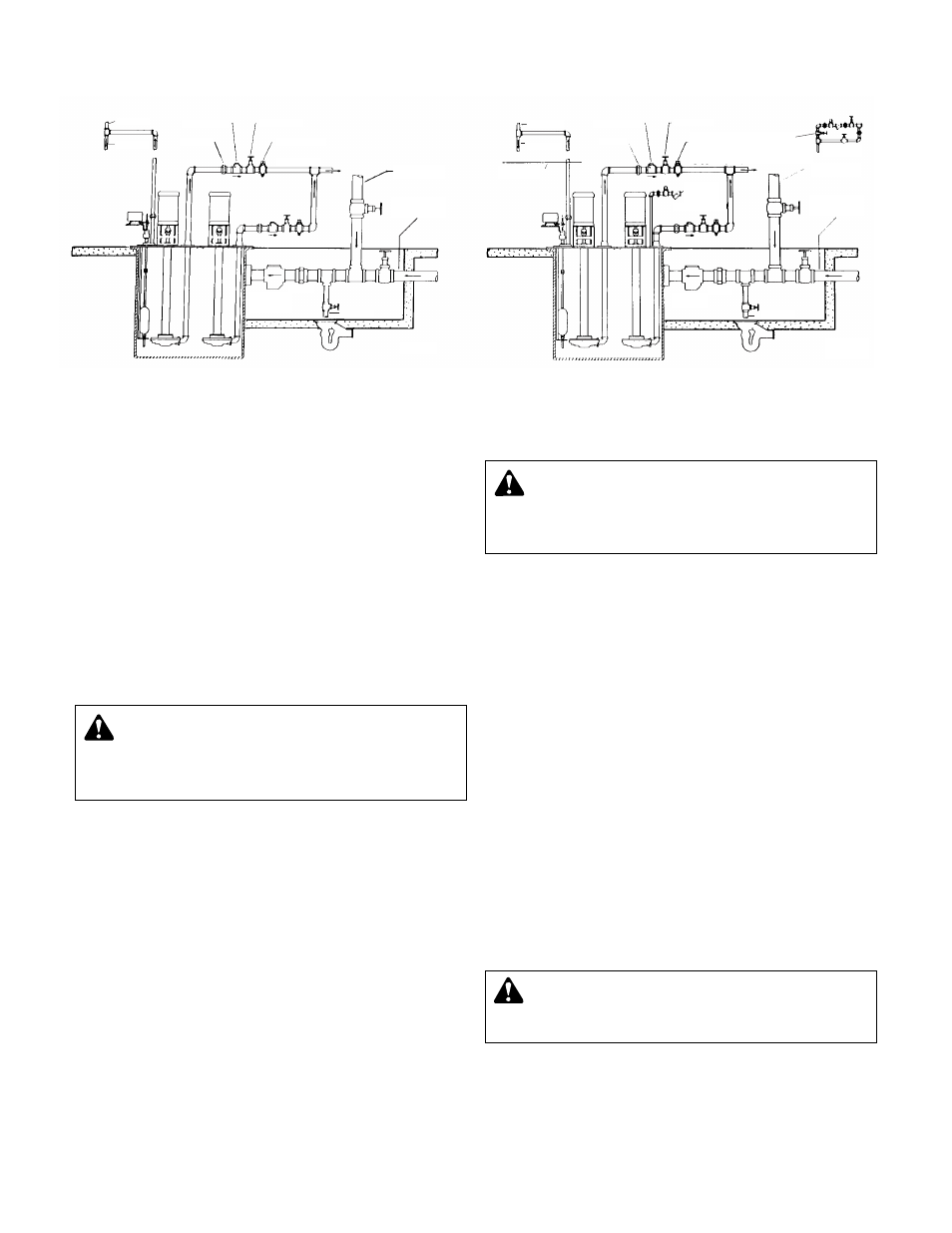

SERIES UH – CONDENSATE UNIT

REPRESENTATIVE PIPING DIAGRAMS

AIR VENT

TO DRAIN

UNION

CHECK VALVE

GATE VALVE

STEAM COCK

DISCHARGE

CONDENSATE

RETURN LINE

UNDERGROUND

CONDENSATE

RETURN LINE

BASKET

STRAINER

(OPTIONAL)

UNION

TO DRAIN

IDPD33

AIR VENT

TO DRAIN

WATER LINE

OF BOILER

UNION

CHECK VALVE

GATE VALVE

STEAM COCK

WATER MAKE-UP

WITH 3 VALVE BYPASS

OPTIONAL

DISCHARGE TO BOILER

DETAIL AA

WATER

MAKE-UP

SUPPLY

(SEE DETAIL AA)

CONDENSATE

RETURN LINE

UNDERGROUND

CONDENSATE

RETURN LINE

BASKET

STRAINER

UNION

TO DRAIN

IDPD44

SERIES UHM BOILER FEED UNIT

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

CAUTION:

NOT A CHEMICAL PUMP

Inject boiler feed compounds from chemical feed

tank into boiler feed piping – never into condensate tank.

Failure to follow these instructions could result in injury or

property damage.

WARNING:

HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.