Pam2861, Application information – Diodes PAM2861 User Manual

Page 8

PAM2861

Document number: DSxxxxx Rev. 1 - 1

8 of 12

July 2013

© Diodes Incorporated

PAM2861

A Product Line of

Diodes Incorporated

Application Information

Setting Nominal Average Output Current with External Resistor R

S

The nominal average output current in the LED(s) is determined by the value of the external current sense resistor (R

S

) connected between VIN

and I

SENSE

and is given by:

R

1

.

0

I

S

)

NOM

(

OUT

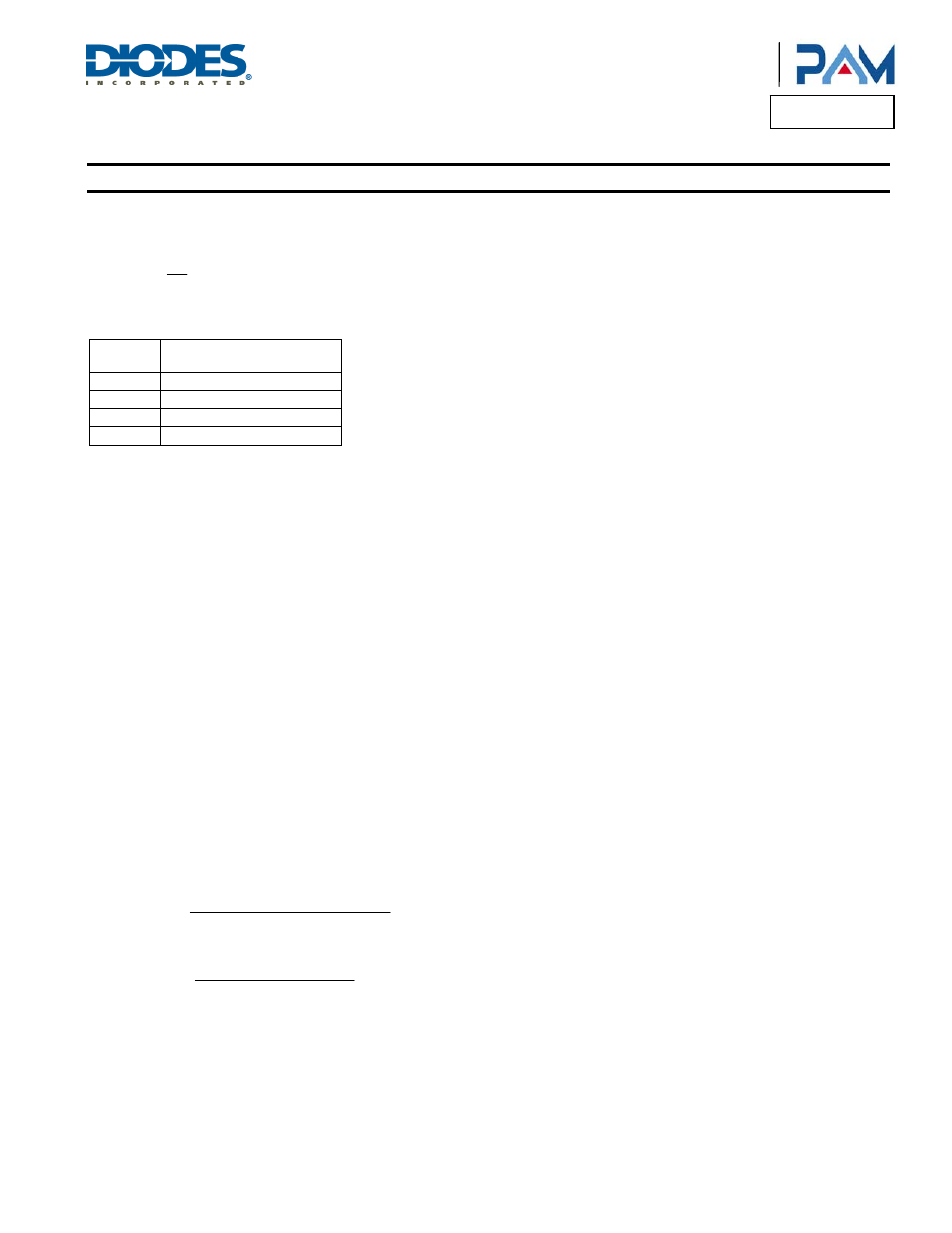

The table below gives values of nominal average output current for several preferred values of current setting resistor (R

S

) in the typical

application circuit shown on page 1.

R

S

(

Ω)

Nominal Average Output

Current (mA)

0.1 1000

0.13 760

0.15 667

0.3 333

The above values assume that the VSET pin is floating and at a nominal voltage of VREF (1.25V). Note that R

S

= 0.1

Ω is the minimum allowed

value of sense resistor under these conditions to maintain switch current below the specified maximum value. It is possible to use different

values of R

S

if the VSET pin is driven from an external voltage.

Capacitor Selection

A low ESR capacitor should be used for input decoupling, as the ESR of this capacitor appears in series with the supply source impedance and

lowers overall efficiency. This capacitor has to supply the relatively high peak current to the coil and smooth the current ripple on the input

supply.

A minimum value of 4.7µF is acceptable if the input source is close to the device, but higher values will improve performance at lower input

voltages, especially when the source impedance is high. The input capacitor should be placed as close as possible to the IC.

For maximum stability over temperature and voltage, capacitors with X7R, X5R, or better dielectric are recommended. Capacitors with

Y5Vdielectric are not suitable for decoupling in this application and should NOT be used.

Inductor Selection

Recommended inductor values for the PAM2861 are in the range 33µH to 100µH. Higher values of inductance are recommended at higher

supply voltages in order to minimize errors due to switching delays, which in increased ripple and lower efficiency. Higher values of inductance

also result in a smaller change in output current over the supply voltage range. The inductor should be mounted as close to the device as

possilbe with low resistance connections to the LX and VIN pins. The chosen coil should have a saturation current higher than the peak output

current and a continuous current rating above the required mean output current.

The inductor value should be chosen to maintain operating duty cycle and switch ‘on’/’off’ times within the specified limits over the supply voltage

and load current range. The following equations can be used as a guide.

LX Switch ‘On’ time

)

R

R

R

(

I

V

V

I

L

T

LX

L

S

LED

LED

IN

ON

Lx Switch ‘Off’ time

)

R

R

(

I

V

V

I

L

T

L

S

LED

D

LED

OFF

Where: L is the coil inductance; R

L

is the coil resistance; R

S

is the current sense resistance I

LED

is the required LED current;

ΔI is the coil peak-

peak ripple current (Internally set to 0.25 x I

LED

); V

IN

is the supply voltage; V

LED

is the total LED forward voltage; R

LX

is the switch resistance

(0.3

Ω nominal); V

D

is the diode forward voltage at the required load current